Dust removal method and device for ground horizontal well of coal mine roadway driving face

A technology for excavating working face and coal mine roadway, which is applied in the directions of safety devices, dust prevention, mining equipment, etc., can solve problems such as reducing coal mining efficiency and the impact of underground roadway space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

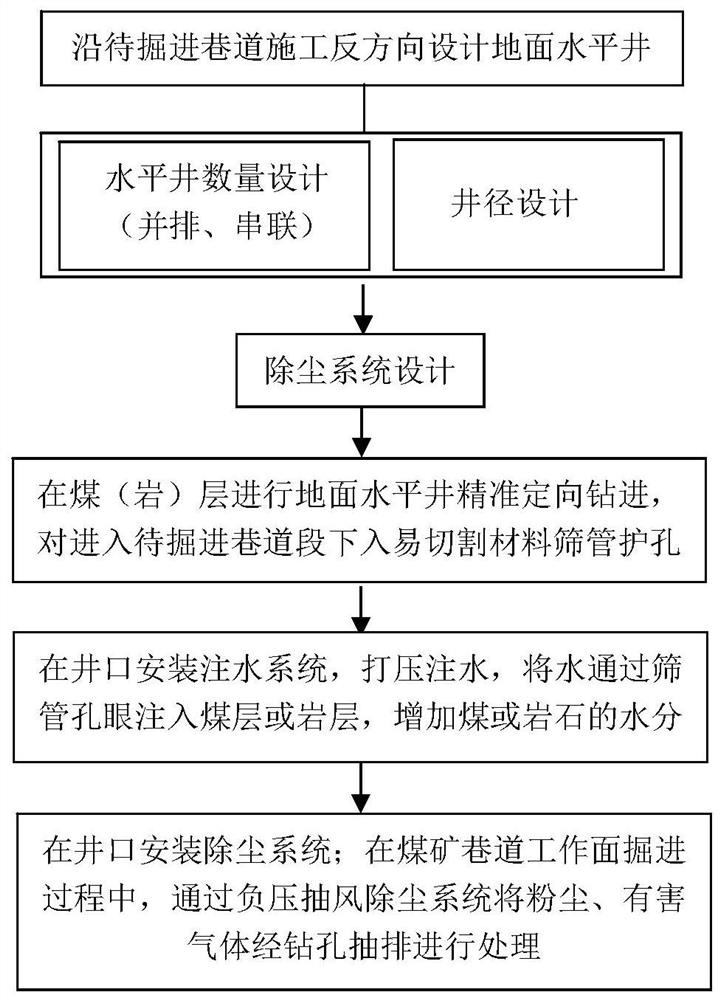

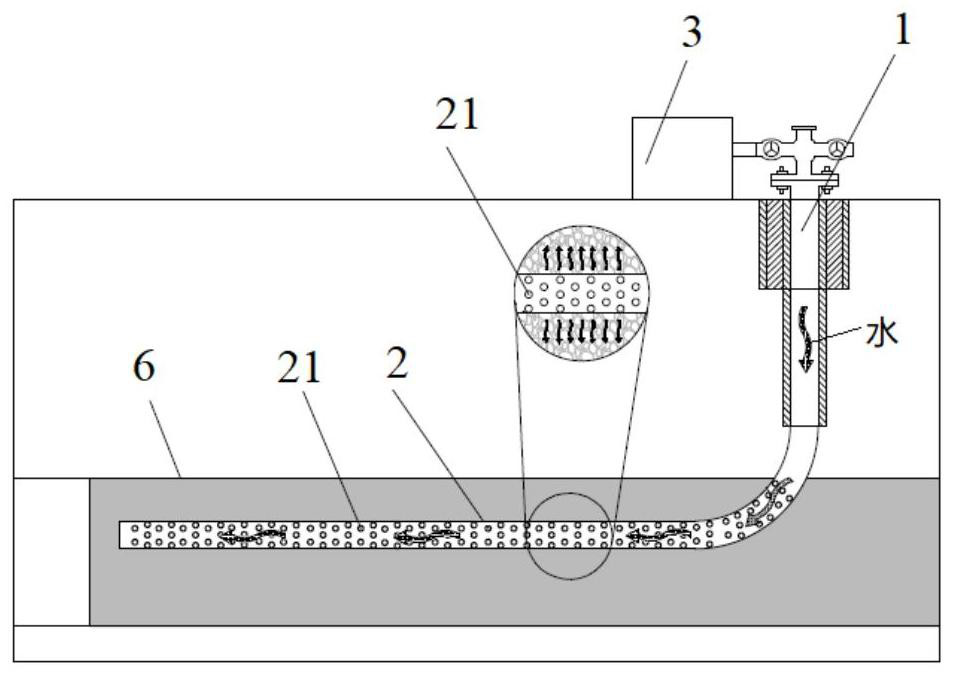

[0066] Taking the tunneling of a coal mine as the background, see Figure 2-Figure 4 , the excavation object is the coal seam with good coal structure, which can construct the ground horizontal well along the coal seam. The roadway has a rectangular section, 3m wide and 2.6m high, and the length of the roadway is 1000m. The excavation process mainly solves problems such as dust and noise, and the specific implementation steps are as follows:

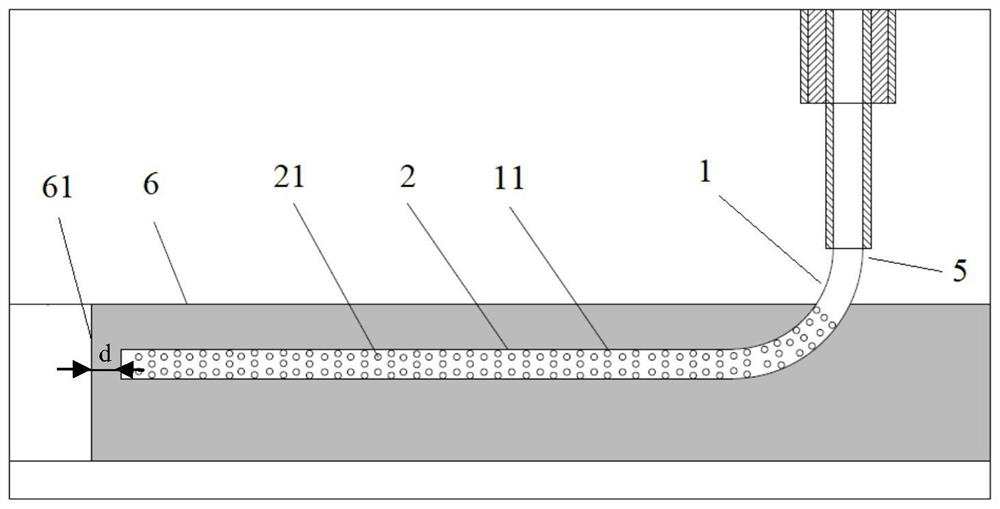

[0067] Step 1: Design a surface horizontal well 1 along the opposite direction of the roadway 6 to be excavated in combination with the size of the roadway section (see figure 2 ), the horizontal section 11 is 1.3-1.8m away from the roadway side in the width direction of the roadway excavation working face, and 1.5-2.55m away from the roadway bottom in the height direction, the length of the horizontal section 11 is 995m, and the horizontal section 11 does not drill through the roadway 6 The starting end 61 of the roadway is completed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com