Composite oxide electrode material and producing method thereof, and mixed super capacitor

A composite oxide and electrode material technology, which is applied in the manufacture of electrolytic capacitors, capacitors, electrodes, etc., can solve the problems of capacity attenuation and achieve the effects of small capacity attenuation, good cycle performance, and stable charge and discharge cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation of embodiment 1 composite oxide electrode material

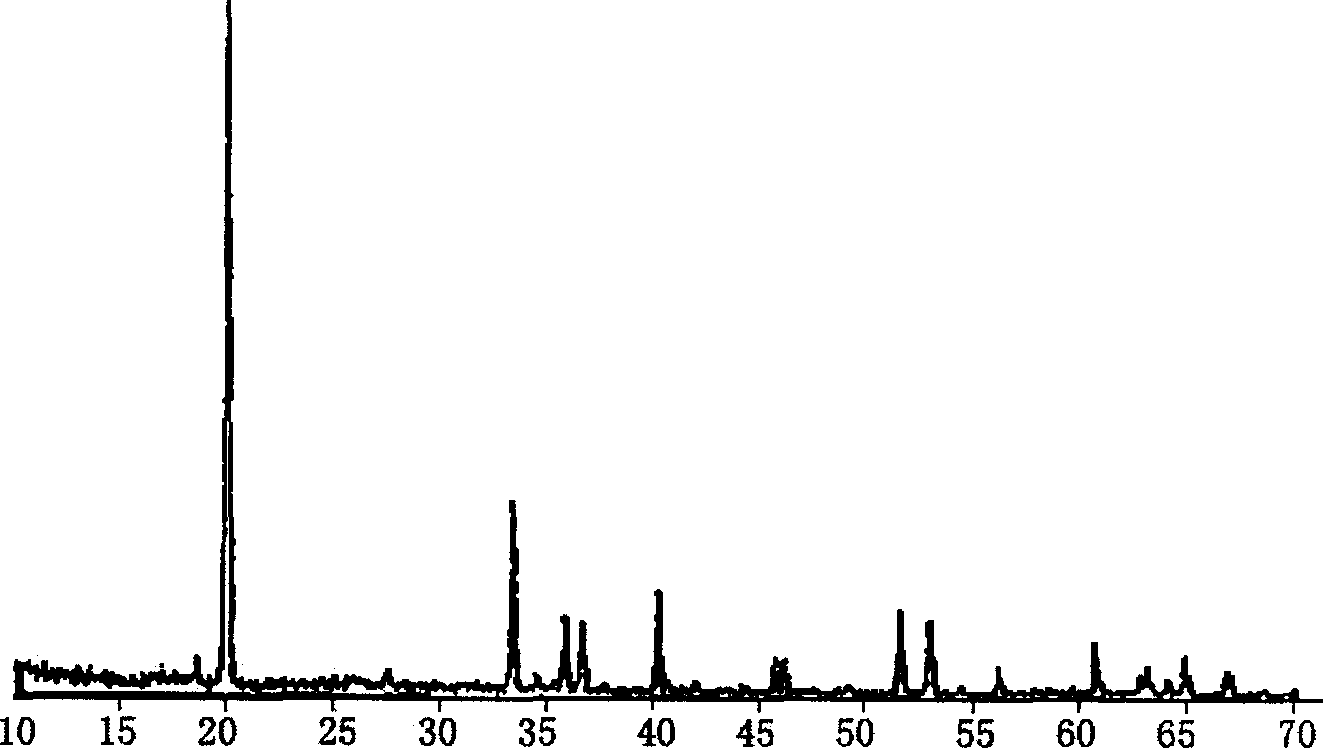

[0036] With Li 2 CO 3 , Anatase TiO 2 According to the ratio of the amount of Li and Ti being 2:3, add it into the ball mill jar equipped with zirconia balls, and use the mixed solution of deionized water, acetone and ethanol as the volume ratio of 1:2.5:3 as the dispersion medium, rotate the ball mill at a rate of 750 rpm for 6 hours, and spray-dry the obtained mixed slurry at 75°C, heat-treat the obtained powder in a muffle furnace at a high temperature of 950±50°C for 14 hours, and obtain a composite oxide electrode after cooling Material. X-ray powder diffraction analysis was carried out to this material, the instrument used is Japan Rigaku D / MAX 2400 diffractometer, test condition is Cukα, 40kV, and the diffraction pattern sees figure 1 . The intensity of each peak reflects the characteristics of the space group Pbnm very well. The parameters of the lattice unit are a=5.07, b=9.53, c=2.94,...

Embodiment 2

[0037] Preparation of embodiment 2 composite oxide electrode material

[0038] The material preparation method of this embodiment is basically the same as that described in Example 1, the difference is that LiOH·H 2 O and anatase TiO 2 The dispersion medium is polyacrylic acid with an average molecular weight of 850. After rotary ball milling, the slurry is dried in an oven at 80°C to form a bulk precursor. The precursor is preformed in an air atmosphere in a muffle furnace at 400°C Heat treatment, when the color turns white and no gas is released, raise the temperature to 950±50°C for 14 hours, and obtain a composite oxide electrode material after cooling.

Embodiment 3

[0039] Preparation of embodiment 3 composite oxide electrode material

[0040] The material preparation method of this embodiment is the same as 1, and its difference is to increase Fe in the raw material 2 o 3 , where Li 2 CO 3 , Anatase TiO 2 , Fe 2 o 3 The amount of the three compounds is 2:2.75:0.25 with the ratio of Li, Ti, Fe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com