Negative electrode material as well as preparation method thereof, and sodium ion secondary battery

A negative electrode material and ion technology, applied in the field of negative electrode materials and its preparation, and sodium ion secondary batteries, can solve the problems of not being well applied, limited specific capacity, volume expansion, etc., and achieve excellent reversible specific capacity and good cycle Effect of performance and high specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention also provides a method for preparing the material described in the above technical solution, which includes the following steps:

[0030] (1) Mix calcium salt, phosphate, organic titanium salt and carbon source with water, and react to obtain a mixture gel;

[0031] (2) Pre-sintering the mixture gel obtained in the step (1) to obtain a mixture precursor;

[0032] (3) Sintering the mixture precursor obtained in the step (2) to obtain a negative electrode material.

[0033] In the present invention, calcium salt, phosphate, organic titanium salt and carbon source are mixed with water and reacted to obtain a mixture gel. In the present invention, the molar ratio of Ca, P, Ti and C in the mixed gel is preferably 0.5 to 1.5: 5 to 7: 3 to 5: 10 to 14, more preferably 0.8 to 1.2: 5.5 to 6.5 : 3.5 to 4.5: 11 to 13, most preferably 1 to 1.1: 6 to 6.2: 4 to 4.2: 11.5 to 12.5. In the present invention, the concentration of the carbon source in water is preferably 0...

Embodiment 1

[0059] Dissolve 0.001 mol of calcium carbonate, 0.006 mol of ammonium dihydrogen phosphate and 0.004 mol of isopropyl titanate in 100 ml of a 0.02 mol / L citric acid solution, and heat and stir at a constant temperature of 70°C until the solution shows a paste-like gel. Mixture gel

[0060] The mixture gel was dried in a drying box at 100°C for 12 hours and then ground into a mixture powder in an agate mortar. The mixture powder was pre-sintered to 350°C under the protection of nitrogen and kept for 7 hours. After natural cooling, it was taken out. Mixture precursor

[0061] The mixture precursor was pressed into tablets under a pressure of 22 MPa, and the flake precursors were sintered to 750° C. under the protection of nitrogen and kept for 15 hours. After natural cooling, they were taken out to obtain the negative electrode material of the sodium ion secondary battery.

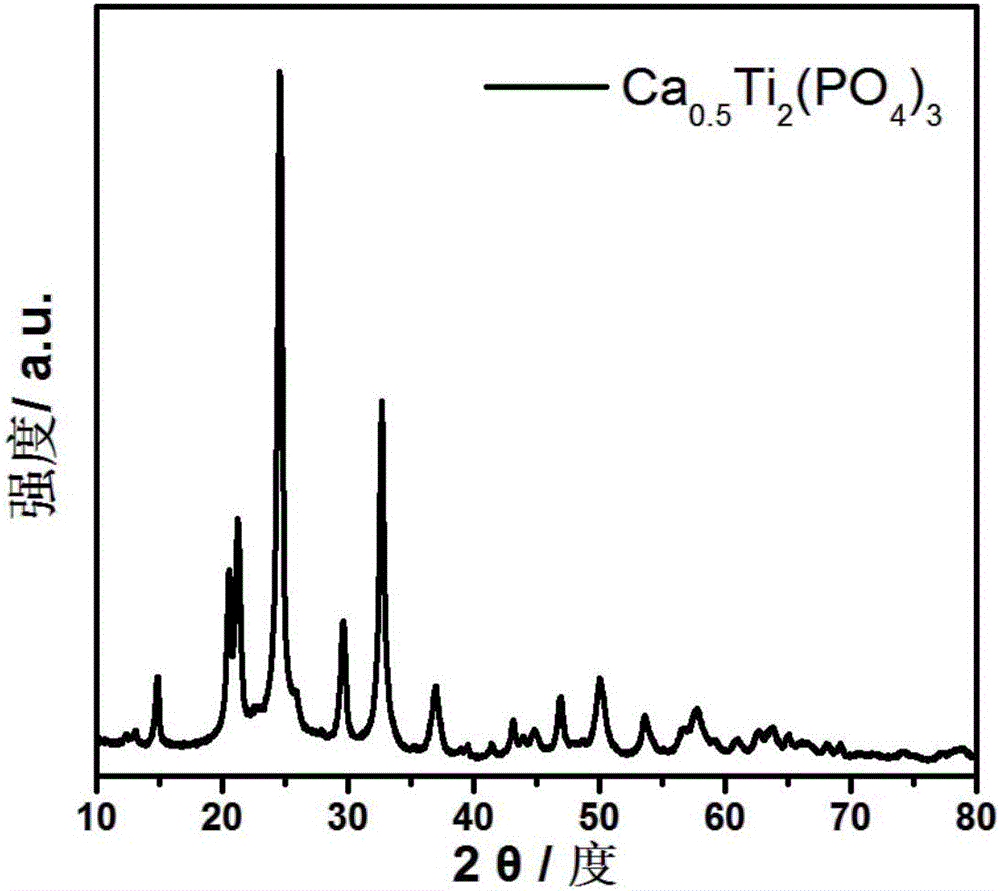

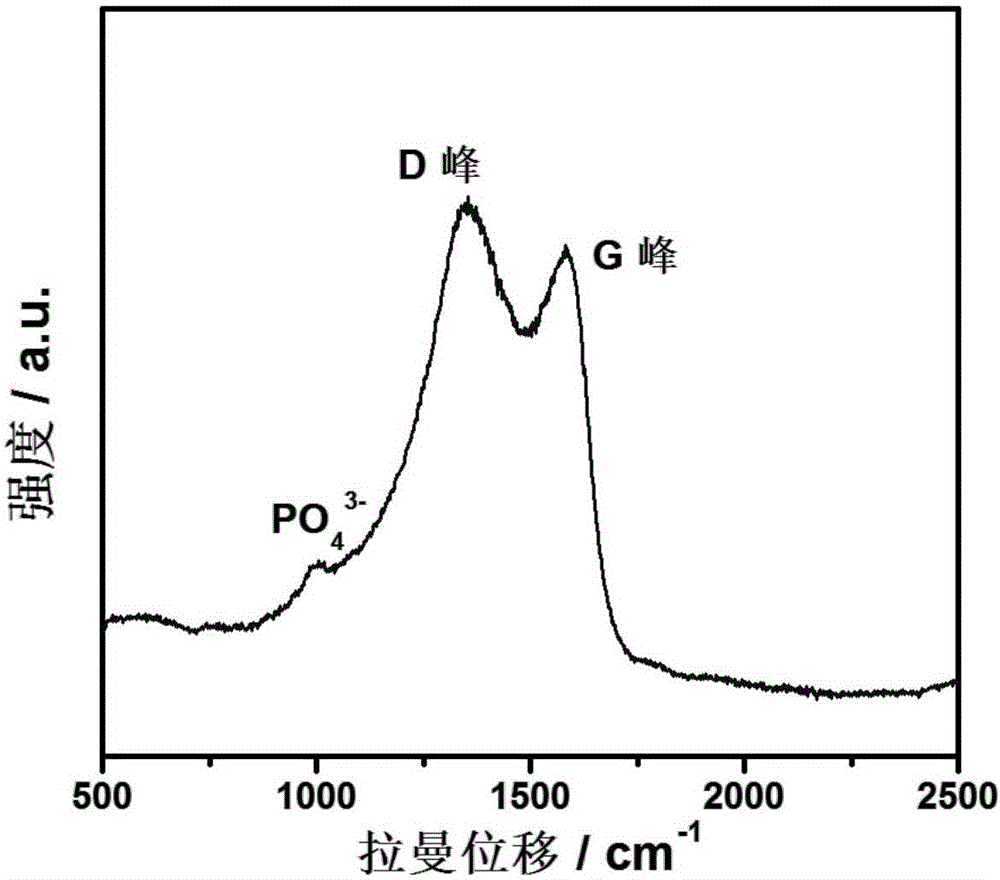

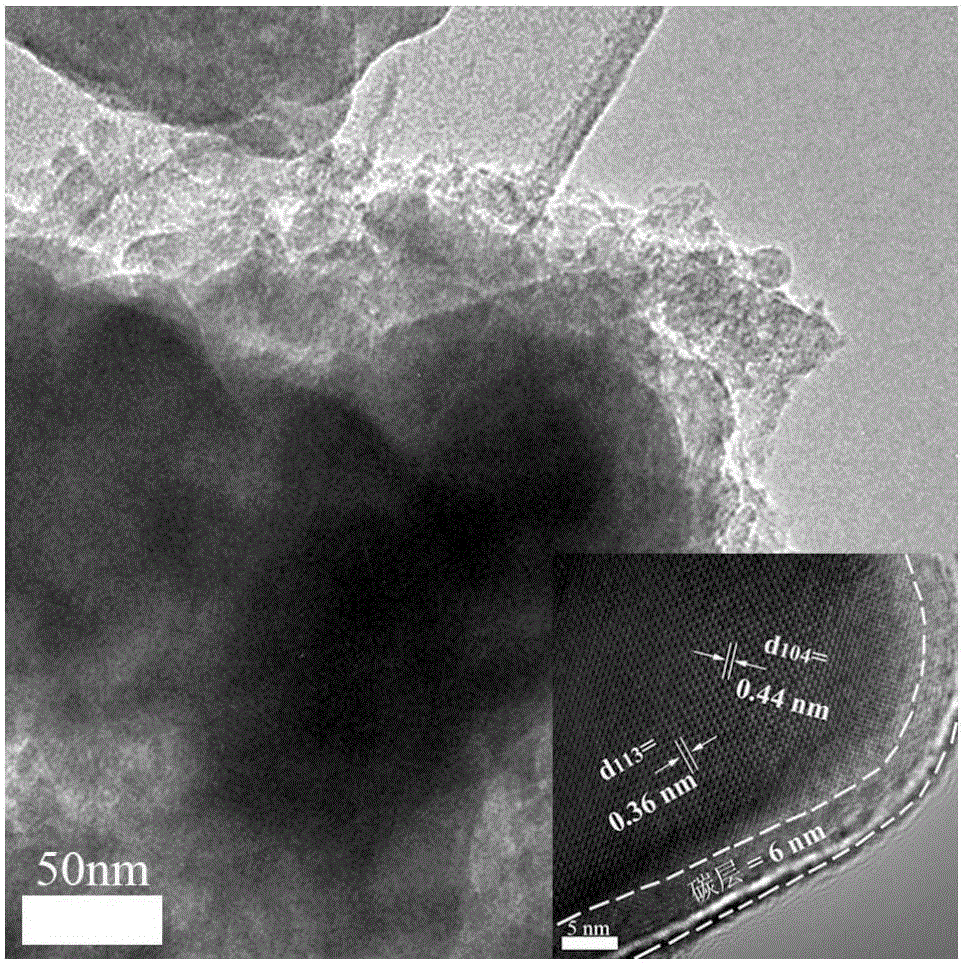

[0062] A Bruker D8 diffractometer equipped with a copper target X-ray tube was used to perform an X-ray powder ...

Embodiment 2

[0066] The negative electrode material prepared in Example 1, acetylene black and PVDF (polyvinylidene fluoride) were mixed into a slurry according to a ratio of 7:2:1, and uniformly coated on the copper foil substrate to obtain an electrode sheet;

[0067] The obtained electrode sheet was dried in a vacuum oven at 120°C for 10 hours, and then compressed under a pressure of 20 MPa, and then the prepared electrode sheet was cut into 8mm×8mm sheets as electrodes, each sheet containing 1.7mg Left and right anode material.

[0068] Use pure sodium tablets as the counter electrode of the half-cell (a disc with a diameter of about 1cm and a thickness of about 3mm), with 1mol / L sodium perchlorate as the solute, dissolved in PC:EC=1:1(v / v ) The organic liquid in the mixed solvent configuration is the electrolyte, which is compatible with the GLASS MICROFIBER FILTERS GF / C TM The diaphragm was assembled into an experimental battery in a glove box filled with argon (water and oxygen content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com