Process for manufacturing beams of vehicle with varied sections

A technology of automobile girders and process methods, which is applied in the field of manufacturing automobile girders, and can solve problems such as poor mechanical properties of variable-section beams, insufficient process performance, and vehicle accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

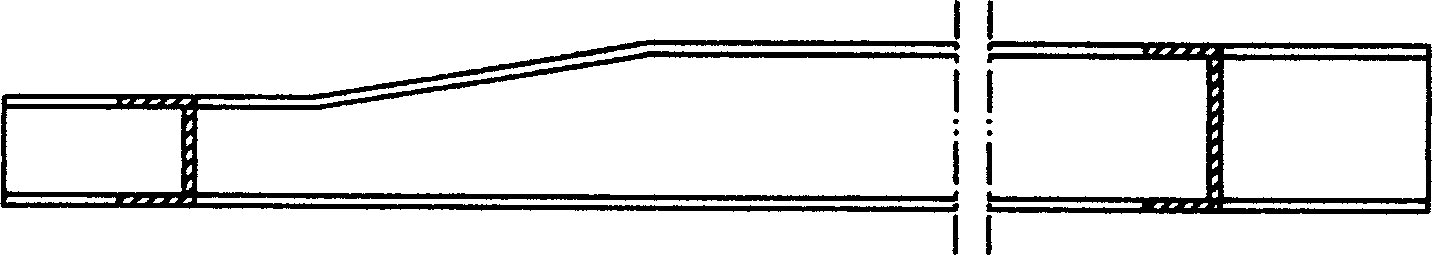

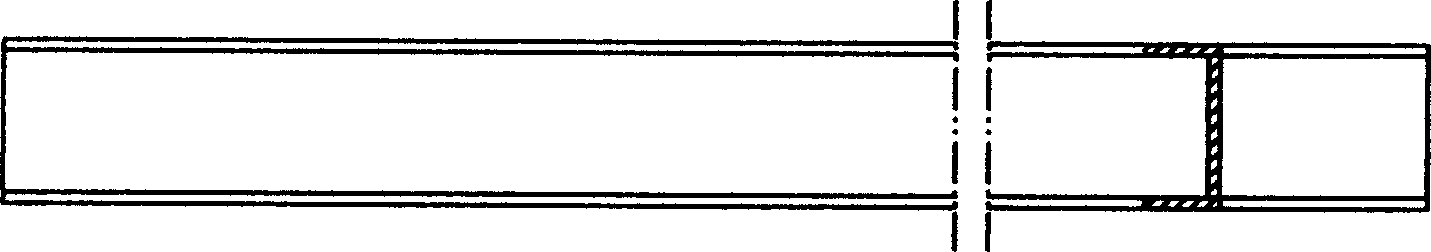

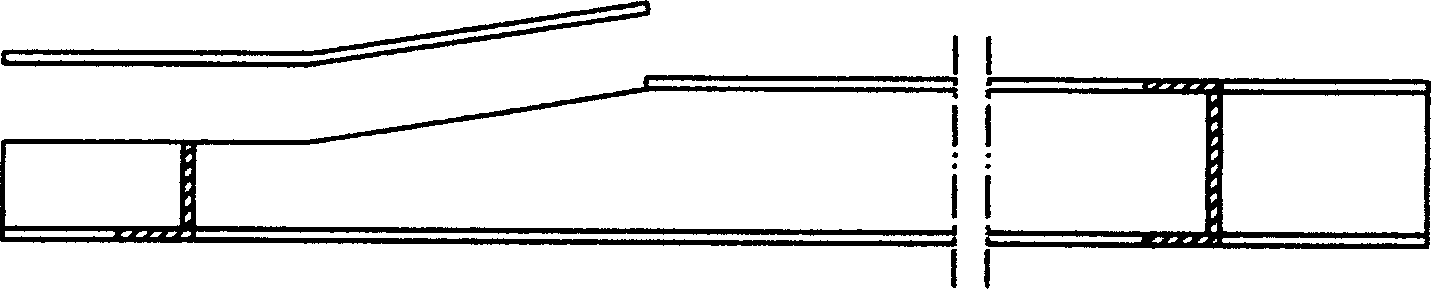

[0010] A kind of technological method of manufacturing automobile variable cross-section girder, its technological process is as follows: figure 2 As shown, firstly, the strip-shaped steel plate meeting the width and length requirements of the automobile girder is rolled into an equilateral channel steel by rolling equipment, and then one end of the equilateral channel steel is stamped and formed into a narrow end channel steel and a transition slope, and then cut off the end channel steel and the side growth of the transition slope, so that the girder blank becomes as attached figure 1 The equilateral variable cross-section automobile frame shown.

[0011] The present invention can process various lengths of automobile variable cross-section girders, the first step process can process the initial blank of automobile variable cross section girders of any length, and the second step process can punch different lengths of automobile variable cross section girders with the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com