Nano-grade glass fibre cotton and mfg. technology and apparatus thereof

A technology of glass fiber wool and manufacturing process, which is applied in the field of glass fiber cotton and can solve the problems of not having the characteristics of nanomaterials and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] formula:

[0039] SiO 2 600g, CaO 50g, Na 2 O 110g, K 2 O 10g, Li 2 O 60g, TiO 2 150g, Al 2 o 3 30g, MgO 20g.

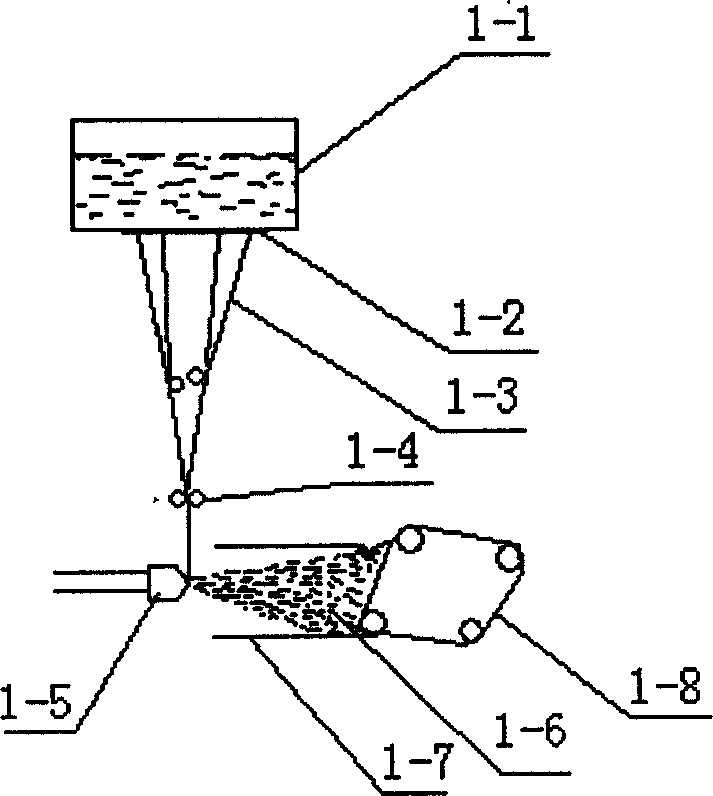

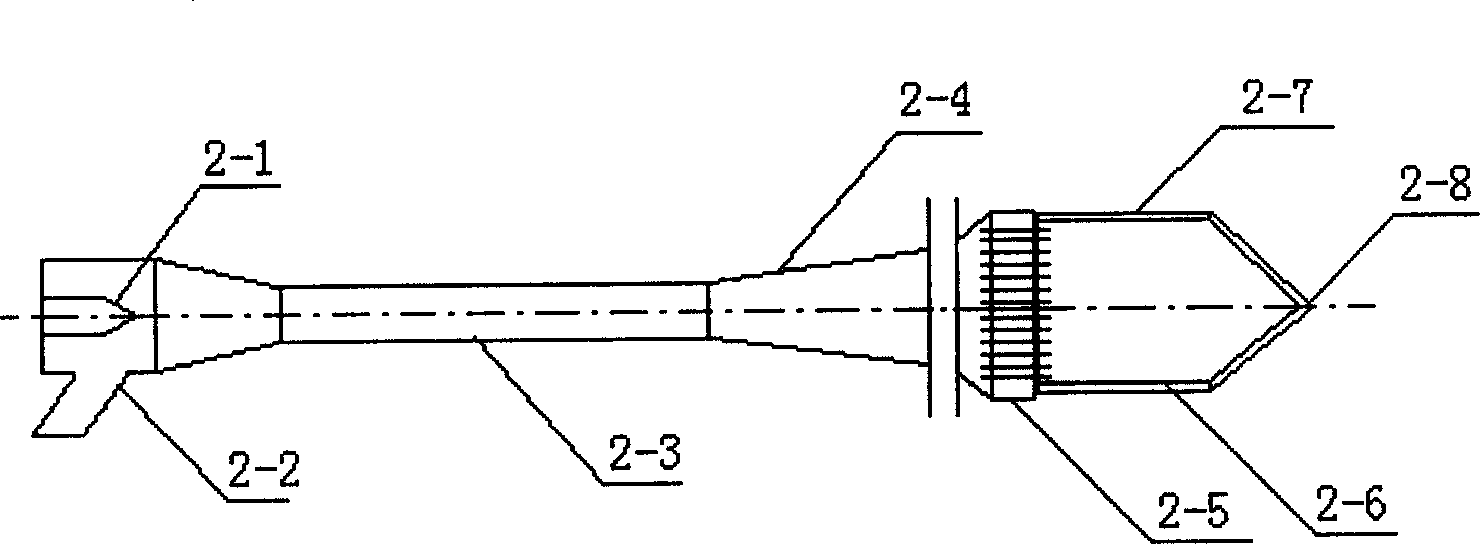

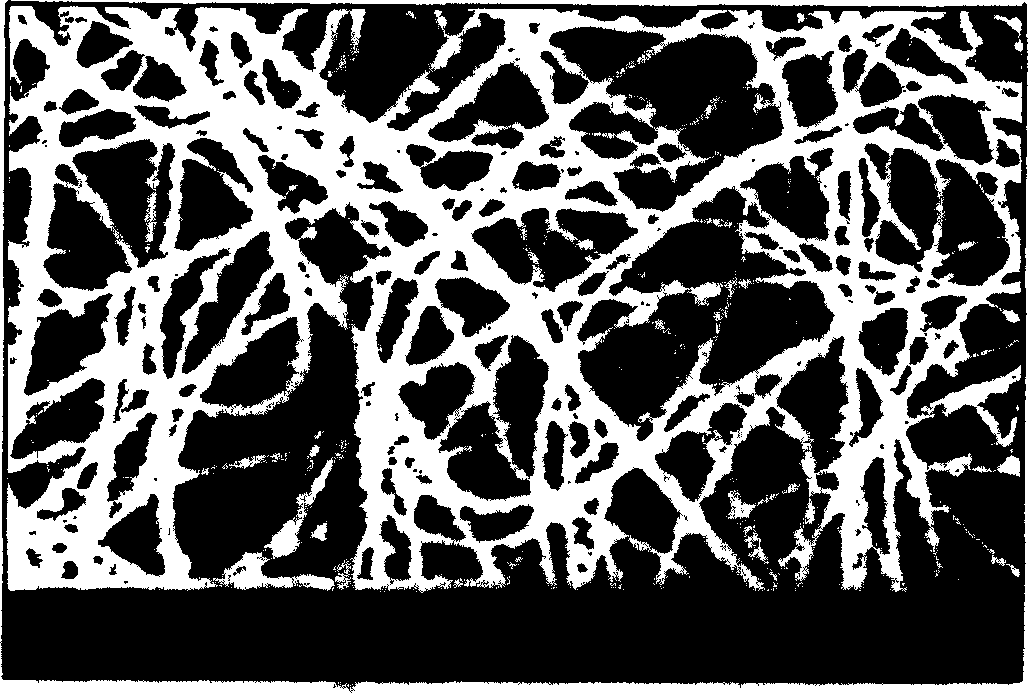

[0040] Manufacturing process (combined with the accompanying drawings in the manual): Take the raw materials according to the formula, wash them, put them into the furnace 1-1 and heat them to 1400°C for melting, the molten glass flows out through the leakage holes of the platinum-rhodium alloy leakage plate 1-2, and the aperture of the leakage nozzle is φ1. 8mm, the drawing speed is 2.5m / min, drawn into fiber 1-3, the diameter of the drawn fiber is controlled at 120μm, pulled by the rubber stick 1-4, sent to the flame ejected from the injection combustion chamber 1-5, using natural gas As the injection medium, at a high temperature above 1500°C and a blowing airflow velocity of 600m / s, use the high-speed airflow ejected from the nozzle of the combustion chamber with a width of 6.0mm to make the glass filament into nano-sized glass fiber cotton 1-6, ...

Embodiment 2

[0042] formula:

[0043] SiO 2 600g, CaO 50g, Na 2 O 110g, K 2 O 10g, Li 2 O 60g, TiO2 150g, Al 2 o 3 30g, MgO20g.

[0044] Manufacturing process (combined with the accompanying drawings in the manual): take the raw materials according to the formula, wash them, send them to the furnace 1-1, heat them at 1400°C and melt them, and the molten glass flows out through the leak holes of the nickel-chromium alloy leak plate 1-2, and the hole diameter of the leak nozzle is 2.8mm , the wire drawing speed is 2.5m / min, drawn into fiber filaments 1-3, the diameter of the drawn fiber filaments is controlled at 150μm, and sent to the flame ejected from the injection combustion chamber 1-5 under the traction of the rubber stick 1-4, using natural gas as the Spray medium, under the high temperature of 1500 ℃ and the blowing air velocity of 600m / s, use the high-speed air flow ejected from the nozzle of the combustion chamber with a width of 6.0mm to make the glass fiber into nano-siz...

Embodiment 3

[0046] formula:

[0047] SiO 2 600g, CaO 50g, Na 2 O 110g, K 2 O 10g, Li 2 O 60g, TiO 2 150g, MgO 20g.

[0048] Manufacturing process (combined with the accompanying drawings in the manual): take the raw materials according to the formula, wash and mix them, send them to the furnace 1-1 and heat them to 1400°C for melting, and the molten glass flows out through the leakage holes of the platinum-rhodium alloy leakage plate 1-2, and the aperture of the leakage nozzle is 1.9mm, the drawing speed is 2.8m / min, drawn into fiber filaments 1-3, the diameter of the drawn fiber filaments is controlled at 150μm, and sent to the flame ejected from the injection combustion chamber 1-5 under the traction of the rubber stick 1-4, using Petroleum liquefied petroleum gas is used as the injection medium, and at a high temperature above 1500°C and an injection airflow velocity of 650m / s, the glass filament is made into nano-sized glass fiber cotton by using the high-speed airflow ejected ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Sound absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com