Polycrystalline structure and its production method

A technology of polycrystalline structure and crystal, which is applied in the fields of record carrier manufacturing, nanostructure application, inductance/transformer/magnet manufacturing, etc. It can solve the problems of not being able to enjoy the diffusion of non-magnetic atoms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

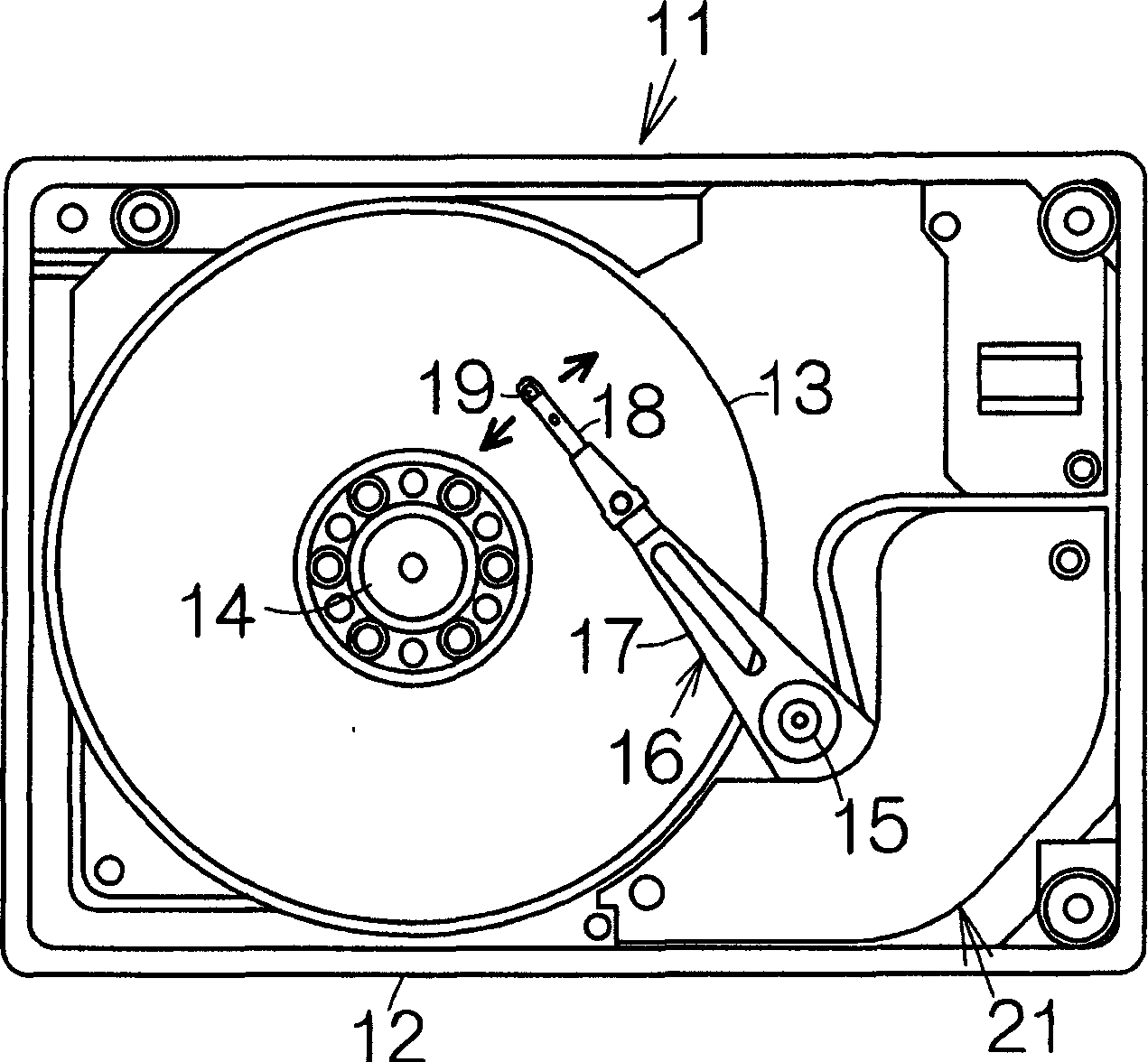

[0034] figure 1It is used to illustrate the configuration of a hard disk drive (HDD) 11 as a specific example of a magnetic recording medium drive or storage device. The HDD 11 includes a box-shaped main housing 12 defining, for example, a flat parallelogram-shaped inner space. At least one magnetic recording disk 13 is accommodated in an inner space within the main casing 12 . The magnetic recording disk 13 is mounted on a drive shaft of a spindle motor 14 . Make the spindle motor 14 drive the magnetic recording disc 13 to rotate at a high speed, such as 7200rpm, 10000rpm and so on. A cover, not shown, is attached to the main housing 12 to define a closed interior space between the main housing 12 and therebetween.

[0035] A carriage 16 is also installed in the inner space of the main housing 12 to swing around the vertical support shaft 15 . The carriage 16 includes a rigid swing arm 17 extending in the horizontal direction from a vertical support shaft 15 and an elasti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| coercivity | aaaaa | aaaaa |

| coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com