Large plate mass concrete seamless construction method

A large-volume concrete and construction method technology, which is applied in the direction of construction, building structure, and building material processing, can solve the problems of inability to guarantee the quality of concrete pouring, numerous procedures, and slow construction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

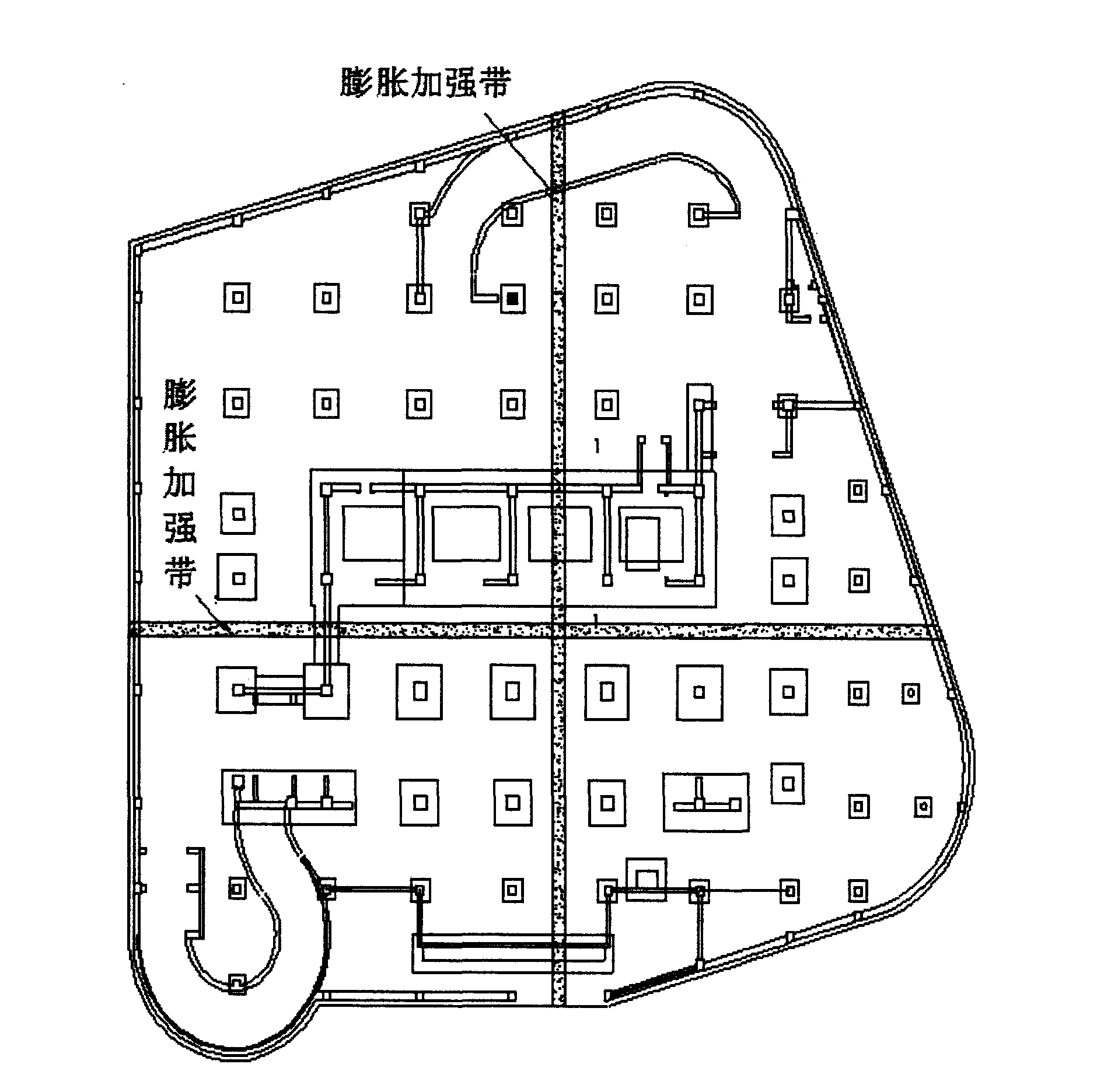

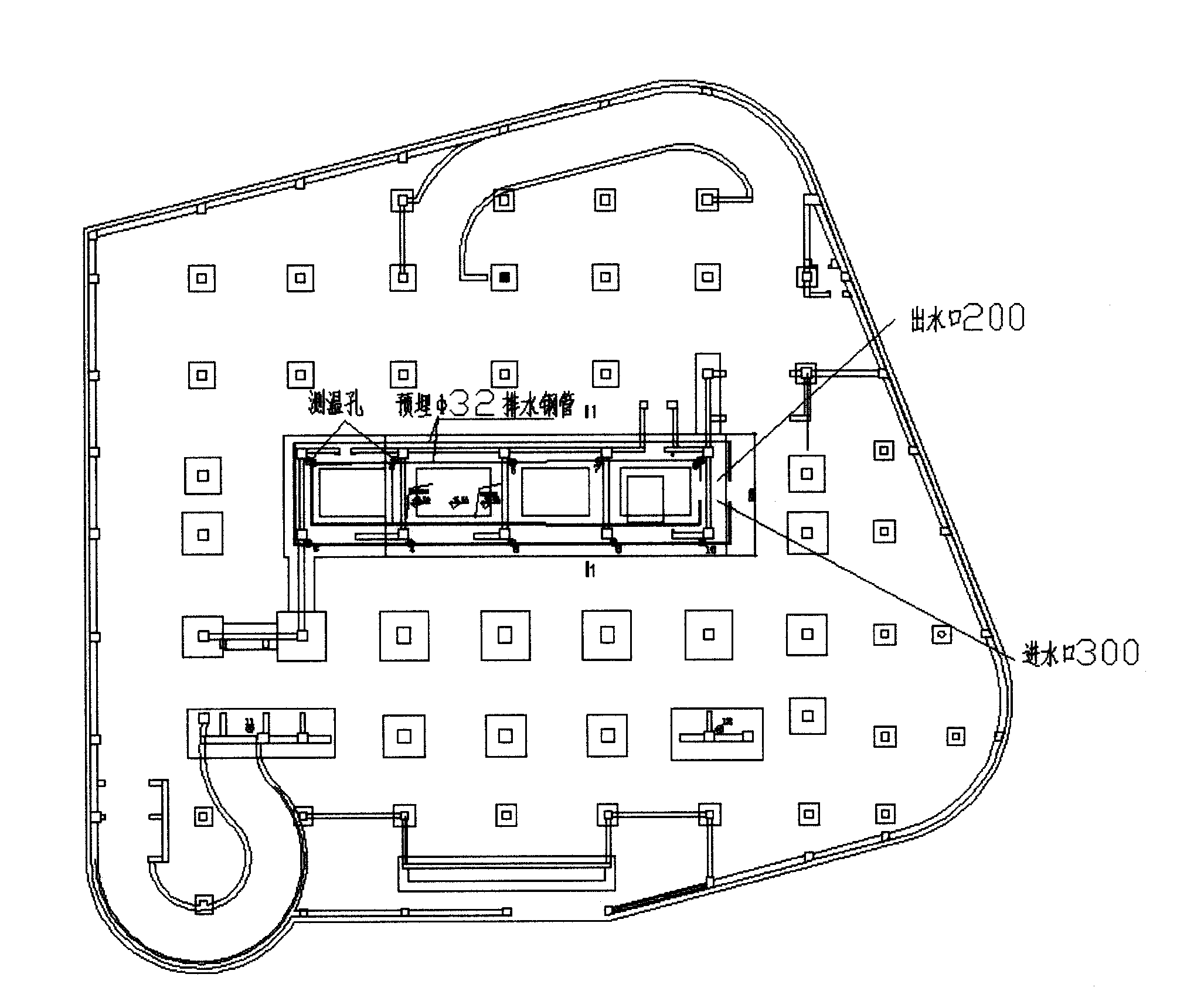

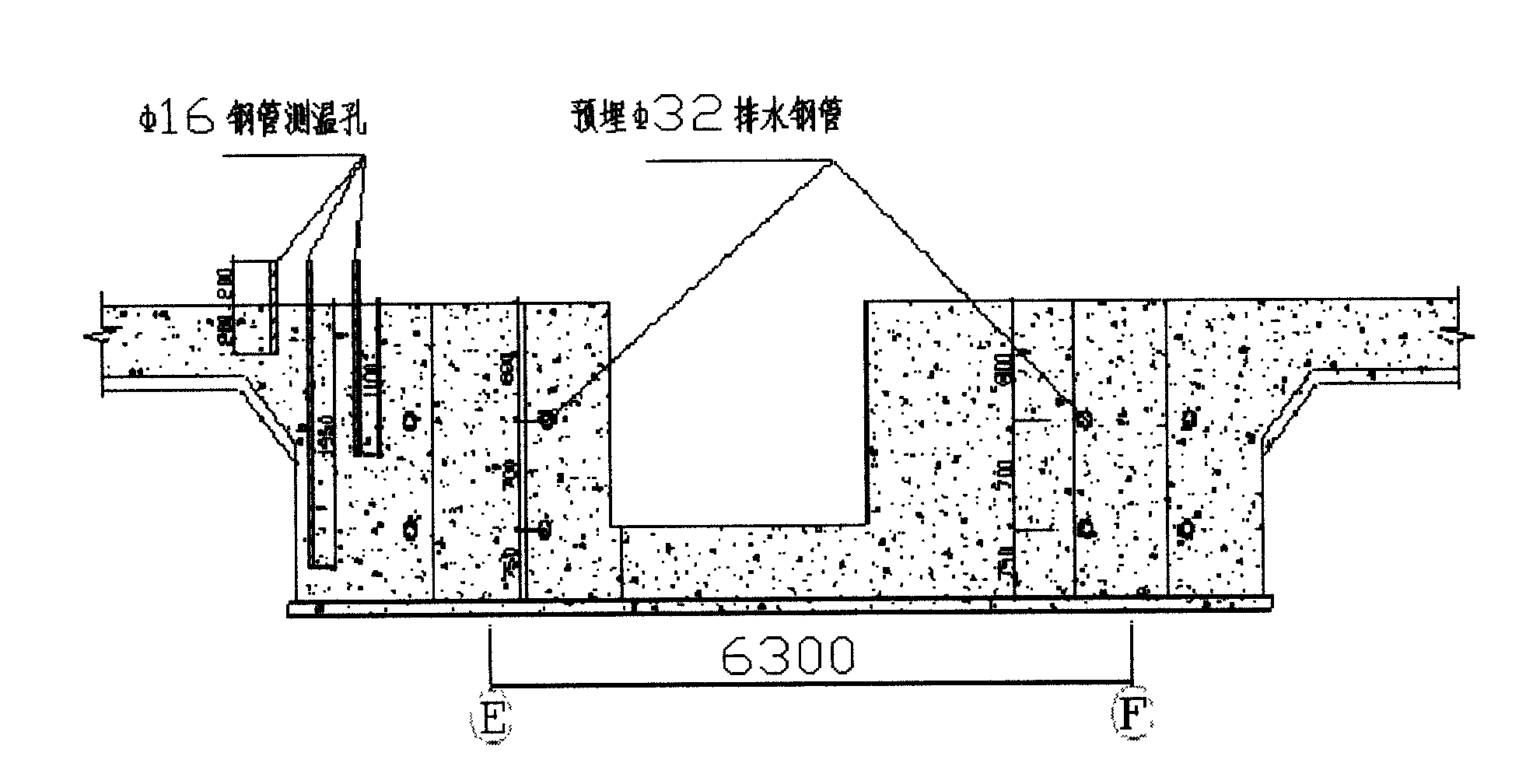

[0016] Hereinafter, specific implementations of the method for seamless construction of large slabs and large-volume concrete according to the present invention will be described with reference to the accompanying drawings.

[0017] First, the inventors of the present application carefully analyzed various causes of cracks in large-area concrete structures.

[0018] (1) Shrinkage cracks in concrete

[0019] If the post-pouring belt is canceled, the problem of concrete cracks that may occur beyond the geometric dimensions specified in the code must be solved. The causes of concrete cracking are extremely complex and can be divided into two major types of action, namely, external load action and deformation action. We call the deformation effect "deformation load", and the cracks caused by it account for more than 80%. Deformation includes air temperature (daily temperature difference and annual temperature difference) production heat source, temperature deformation caused by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com