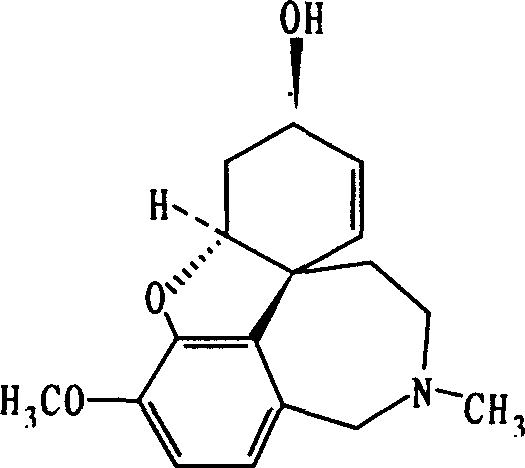

Method for separating galanthamine from plant extract

A technology of plant extracts and galantamine, applied in the direction of organic chemistry, can solve problems that have not been seen, and achieve the effects of less consumption of raw materials, high yield, and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Amaryllidaceae plant extract 10kg, add 1% hydrochloric acid solution to dissolve, adjust and maintain the acidity of the solution. Remove the insoluble particles in the solution by filtration, exchange through a well-balanced STREAMLINE SP cation exchange resin (2L), wash the resin with water to neutrality, carry out gradient elution with 1mol / L sodium chloride solution, track and detect with TLC method, collect Has the same R as Galantamine f Value fractions were basified to pH 9.2 with saturated sodium carbonate solution, extracted 5 times with ethyl acetate (500ml×2, 250ml×3), dried over anhydrous sodium sulfate, and distilled to dryness under reduced pressure to obtain galantamine 10.2 g of the free base crude product was recrystallized with acetone to obtain 8.0 g of galantamine free base crystals with a content of about 99%.

Embodiment 2

[0029] Amaryllidaceae plant extract 10kg, add 1% hydrochloric acid solution to dissolve, adjust and maintain the acidity of the solution. Remove the insoluble particles in the solution by filtration, exchange through the transformed Amberlite CG-120 cation exchange resin (10L), wash the resin with water to neutrality, carry out gradient elution with 5% ammonia water / ethanol solution, track and detect with TLC method, collect Has the same R as Galantamine f Fractions of value, distillation recovery ethanol. The solution was adjusted to pH 9.2, extracted 5 times with chloroform (500ml×2, 250ml×3), dried over anhydrous sodium sulfate, and distilled to dryness under reduced pressure to obtain 13.1g of crude galantamine free base, which was recrystallized with acetone to obtain 8.5 g of galantamine free alkali crystals with a content of about 99%.

Embodiment 3

[0031] Amaryllidaceae plant extract 10kg, add 1% hydrochloric acid solution to dissolve, adjust and maintain the acidity of the solution. Remove the insoluble particles in the solution by filtration, exchange through the transformed STREAMLINE SP cation exchange resin (2L), wash the resin with water to neutrality, and use 0.1mol / L, 0.2mol / L, 0.3mol / L, 0.4mol / L respectively , 0.6mol / L, 0.8mol / L sodium chloride / 20% ethanol solution for elution, follow-up detection with TLC method, collection and galantamine have the same R f Value fractions were basified to pH 9.2 with saturated sodium carbonate solution, extracted 5 times with ethyl acetate (500ml×2, 250ml×3), dried over anhydrous sodium sulfate, and distilled to dryness under reduced pressure to obtain galantamine 10.5 g of the free base crude product was recrystallized from acetone to obtain 8.1 g of galantamine free base crystals with a content of about 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com