Method for driving induction motor

A technology of induction motor, driving method, applied in the direction of starter, motor generator/starter, motor generator control, etc. of a single polyphase induction motor, which can solve trial errors, difficult to achieve optimal adjustment, long time, etc. problem, to achieve the effect of large output torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

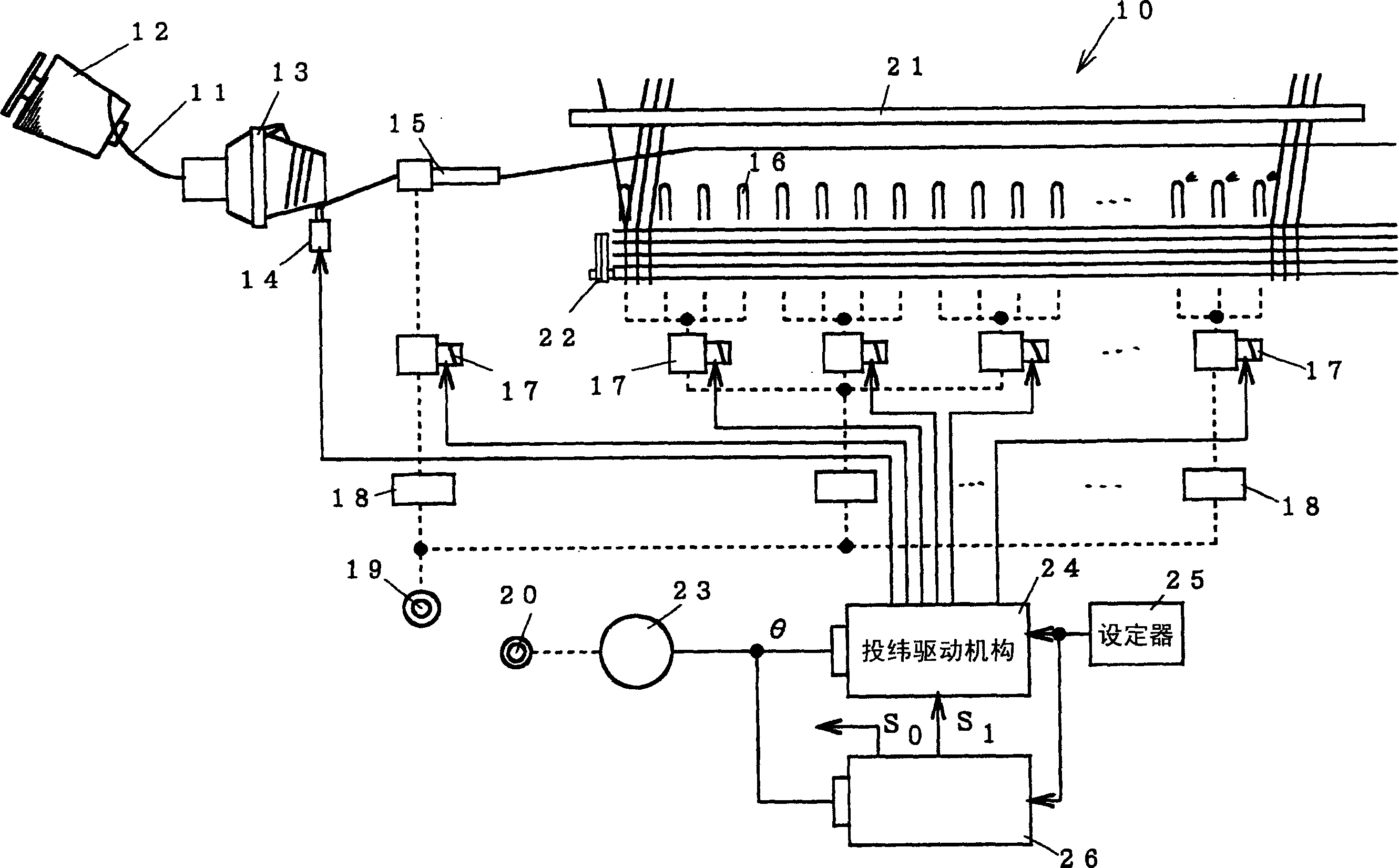

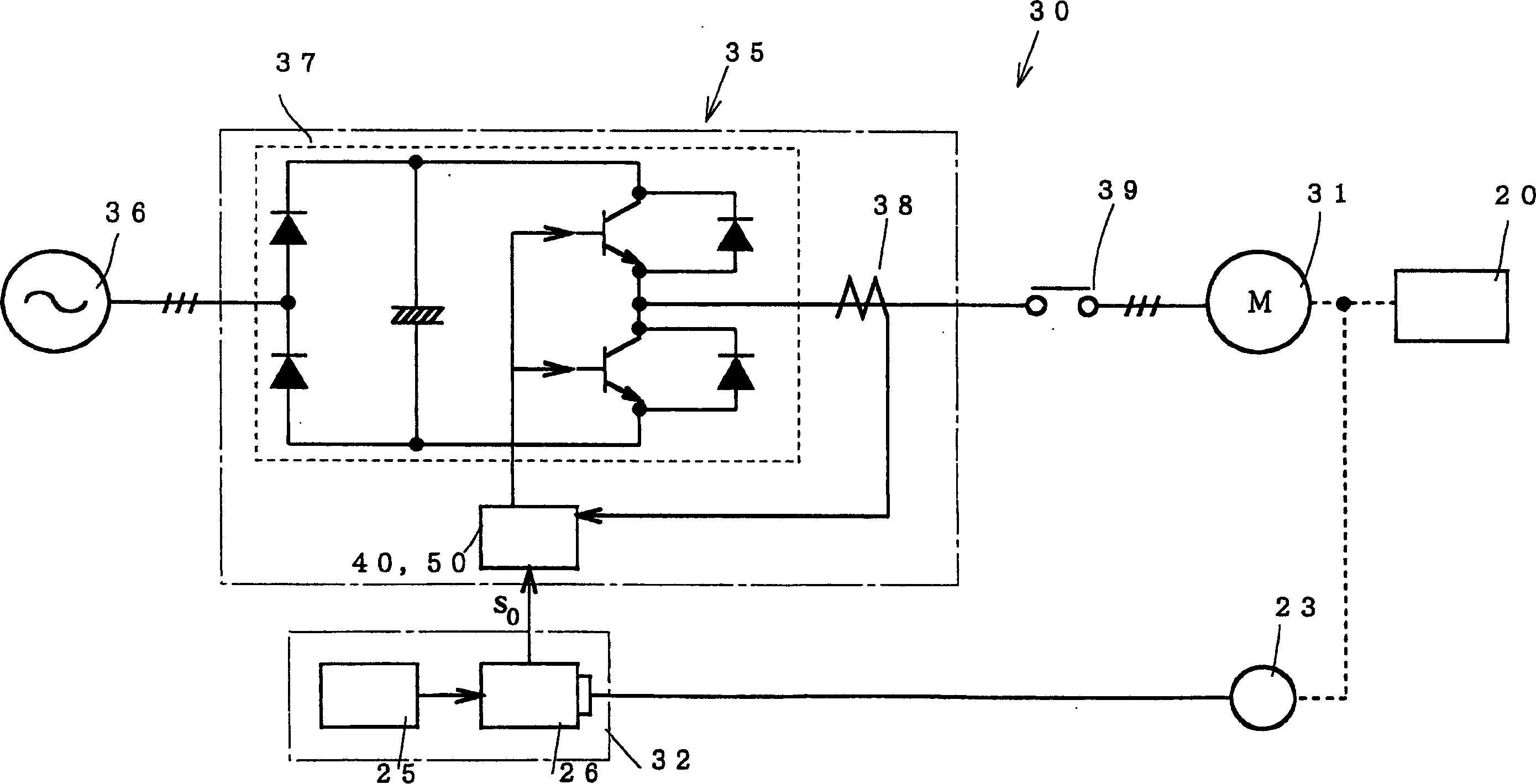

[0037] Hereinafter, specific embodiments of the present invention will be described with reference to the drawings. figure 1 It represents a kind of loom in fiber machinery, and more specifically, it represents the multi-color weft insertion that switches the number of revolutions of the loom while switching the weft yarn type of a weaving condition corresponding to the number of weft insertion and picks. Air jet loom.

[0038] In the loom 10, there is a yarn feeding body 12 for supplying the weft yarn 11, a weft yarn length measuring device 13, a stop pin 14 arranged thereon, and a main nozzle 15 for weft insertion of the weft yarn 11 by air jetting and a controlled A plurality of sub-nozzles 16 are arranged in the warp yarn opening on the way of the flying weft yarn and assist the flying weft yarn 11 by spraying air. The main nozzle 15 is connected to a pressure regulating device 18 constituted by, for example, an electropneumatic proportional valve or the like via an elect...

no. 2 Embodiment

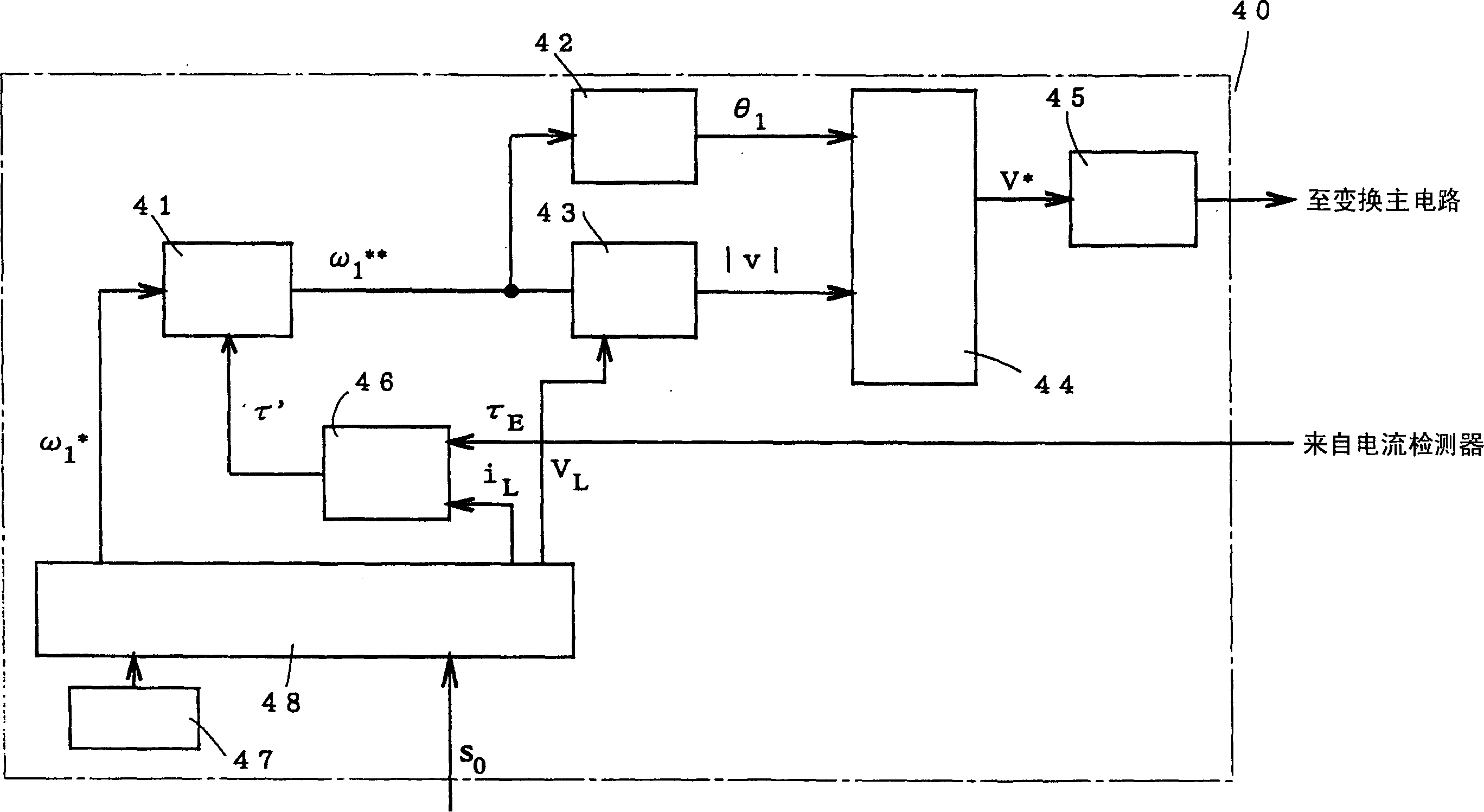

[0062] As the conversion device, besides a device in which the output voltage is controlled by so-called V / f, a device in which the output voltage is controlled by vector calculation can also be used. Figure 11 The internal block diagram of the control circuit 50 using such a conversion device is shown, and more specifically, the slip frequency ω detected as the rotation speed of the induction motor 31 is shown. S , and by making the slip frequency ω S Corresponding to the changed frequency setting value and exceeding the determined specified value ω S0 , A circuit that can return to the normal state voltage. and compared to image 3 , adding a vector operator 52, a coordinate converter 51, and a slip frequency arrival detector 53 with the same function as the above-mentioned comparator 55, for the other parts, because and image 3 The parts shown have the same functions, so the same symbols are attached and explanations thereof are omitted.

[0063] In the control circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com