Semiconductor light emitting device and manufacturing method for the same

A technology for light-emitting devices and semiconductors, which is applied to the structural details of semiconductor devices, semiconductor lasers, and semiconductor lasers. , the effect of avoiding characteristic deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

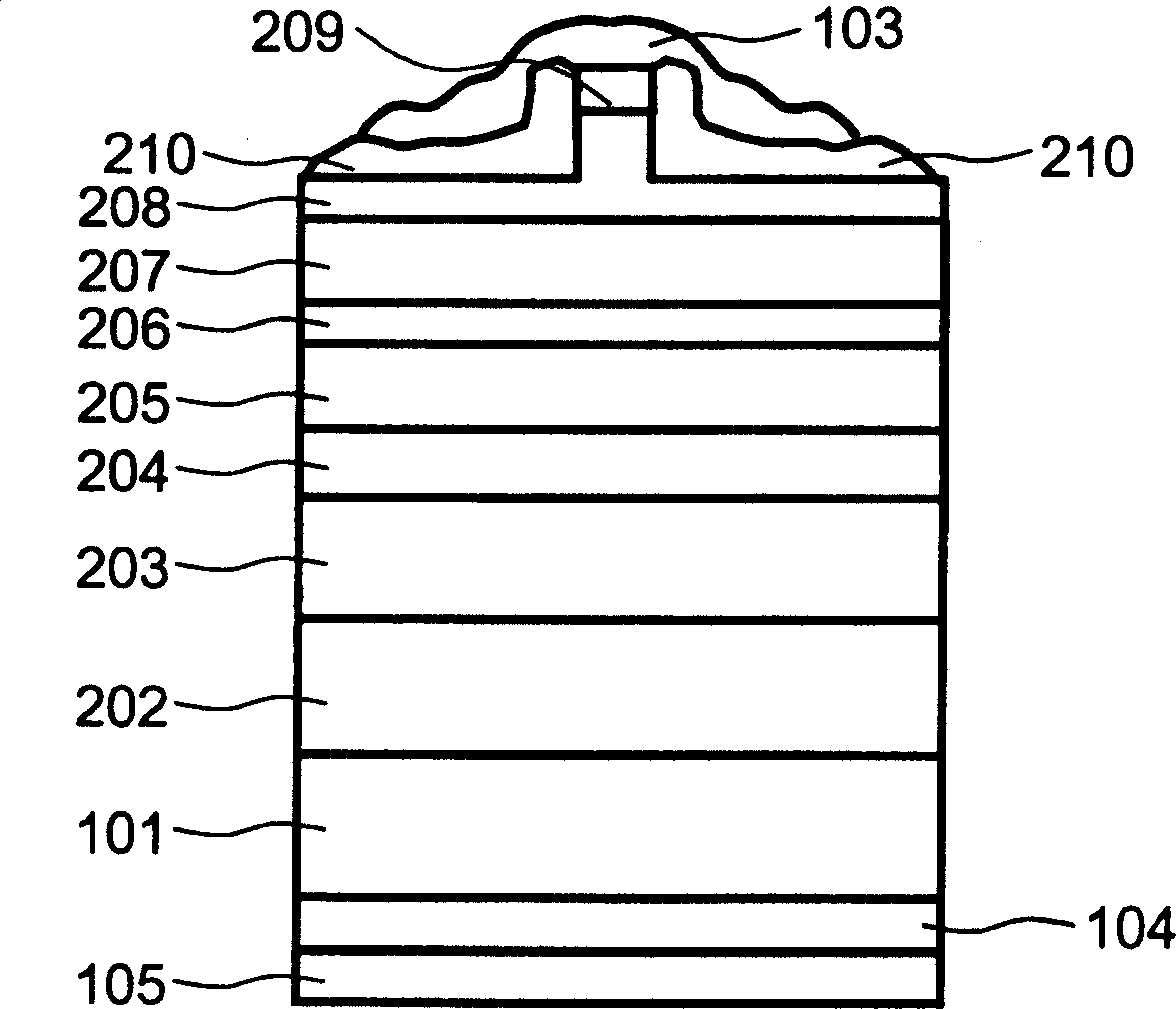

[0023] FIG. 1 is a side view of a semiconductor laser device 100 according to a first embodiment. In FIG. 1 , a nitrogen-based semiconductor layered body 102 is formed on a GaN substrate 101 . Furthermore, p-electrode 103 is provided on the upper surface of nitrogen-based semiconductor layered body 102 , and n-electrode 104 and multilayer metal film 105 a for metallization are provided under the lower surface of GaN substrate 101 .

[0024] The basic structure of the semiconductor laser chip used in the semiconductor laser device 100 according to the first embodiment is as described above, and its details will be described below.

[0025] Via heat spreader 110 , the semiconductor laser chip is protected and layered on support base 120 . The semiconductor laser chip is connected to the heat sink 110 together with the p-electrode 103 facing upward via the solder 112 and the multilayer metal film 105b. Then, the heat sink 110 is connected to the support base 120 via the multila...

no. 2 example

[0044] By changing the material of the solder 113 transcribed to the support base 120 in the semiconductor laser device according to the first embodiment to SnAgCu, the semiconductor laser device according to the second embodiment is obtained. The same numerals denote the same constituent parts as those of the first embodiment, except that numeral 113a denoting the above-mentioned solder is used to describe the second embodiment.

[0045] A Teflon tape with a length of 500 mm and a width of 600 μm was prepared, and the SnAg 0.03 Cu 0.005 Deposited from the vapor form onto a Teflon tape to have a thickness of about 8 μm. Subsequently, the Teflon tape on which the SnAgCu solder 113 a is deposited is placed relative to the supporting base 120 . After placement, ultrasonic vibration of about 80 kHz was applied to the solder 113 a through the Teflon tape, so that the solder 113 a having dimensions of 500 μm length×500 μm width×8 μm thickness was transcribed onto the supporting ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com