Dielectric ceramic material for piece type capacitor and preparing method thereof

A technology for dielectric ceramics and capacitors, applied in the field of chip capacitors, can solve the problems of difficulty in obtaining fine crystals, insulation resistance and dielectric coefficient temperature characteristics have a great influence on grain size, low dielectric coefficient, etc. The effect of flat temperature characteristics and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Principal component expression Ba m (Ti 1-x Zr x )O 3 Among them, m=1.01, x=0.015; the first auxiliary component selects Mg(NO 3 ) 2 ·6H 2 O, based on the main component as 100mol%, Mg(NO 3 ) 2 ·6H 2 The amount of O added was 1.0 mol%.

[0055] BaTiO produced by the oxalic acid method 3 and analytically pure feedstock: BaCO 3 , ZrO 2 , Mg(NO 3 ) 2 ·6H 2 O According to the above chemical composition ratio, add pure water, mix ball mill evenly, dry it by spray drying method, put it in resistance furnace and calcined under air atmosphere, the calcining temperature is 1200°C, keep it warm for 2 hours, add water after cooling, place it in high-speed ball mill for 5 hours ball milling , to obtain the main material after drying.

[0056] Production of the third sub-component: BaCO 3 , CaCO 3 , B 2 o 3 , SiO 2 The molar ratio is: 1.0:0.5:1.5:1.0, weighed and mixed, placed in a crucible, heated to 1350°C and melted, then made into glass cullet by water coolin...

Embodiment 2

[0072] The glassy material (the 3rd subcomponent in the material composition) of four kinds of chemical composition is made with the same process of embodiment 1, and its chemical composition mol ratio is respectively:

[0073] Glassy material A: BaCO 3 : CaCO 3 :B 2 o 3 : SiO 2 =1.0:0.5:1.5:1.0

[0074] Glassy material B: BaCO 3 : CaCO 3 :B 2 o 3 : SiO 2 =1.0:1.0:2.0:1.0

[0075] Glassy material C: BaCO 3 : CaCO 3 :B 2 o 3 : SiO 2 =1.0:0.1:1.0:0.5

[0076] Glassy material D: BaCO 3 : CaCO 3 :B 2 o 3 : SiO 2 =1.0:0.5:1.5:1.5

[0077] Principal component expression Ba m (Ti 1-x Zr x )O 3 In, let m=1.01, x=0.015

[0078] Magnesium nitrate [Mg(NO 3 ) 2 ·6H 2O], its addition amount is 1.0mol%.

[0079] MnO as one of the second subcomponents 2 MnCO 3 The form is added, the addition amount is 0.12mol%, as one of the second subcomponents Re 2 o 3 Choose Y 2 o 3 and Dy 2 o 3 0.4 mol% of each was added.

[0080] BaTiO produced by the oxalic acid m...

Embodiment 3

[0086] The glassy material A (the third subcomponent in the material composition) was produced by the same process as in Example 2, and the addition amount was: 1.5wt%.

[0087] MnO as one of the second subcomponents 2 MnCO 3 The form is added, the addition amount is 0.15mol%, as one of the second subcomponents Re 2 o 3 Choose Y 2 o 3 and Dy 2 o 3 0.4 mol% of each was added.

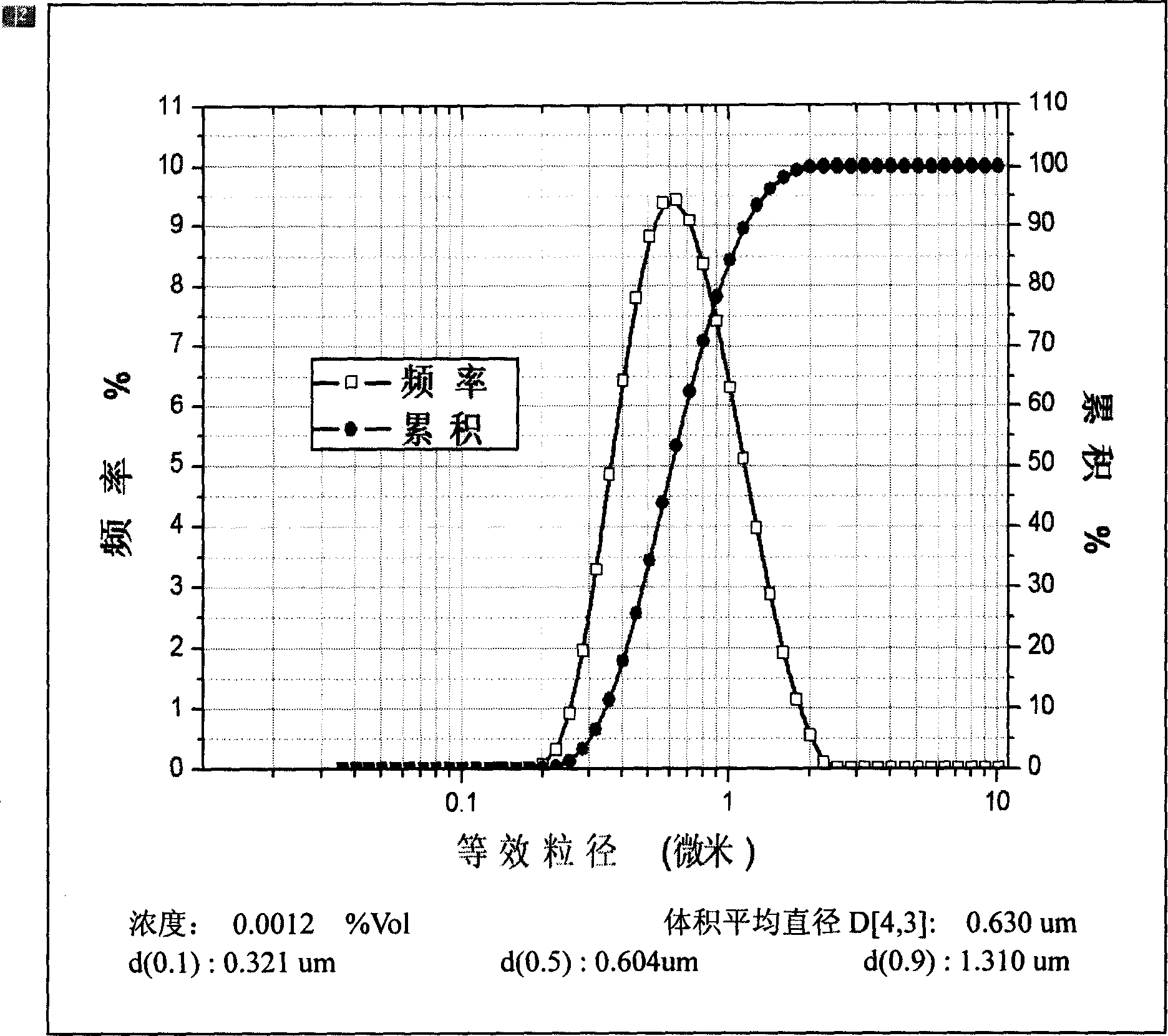

[0088] The material numbered 113 is BaTiO produced by hydrothermal method. 3 Raw materials, whose powder particle size is less than 200nm when observed under a scanning electron microscope.

[0089] As the first subcomponent, number 113 selects MgO for use, and the consumption is 1.0mol%, and other number materials select magnesium nitrate [Mg(NO 3 ) 2 ·6H 2 O], the dosage is listed in Table 5.

[0090] BaTiO 3 and analytically pure BaCO 3 , ZrO 2 , the first auxiliary component is according to the chemical composition ratio listed in Table 5, plus pure water, mixed ball mill evenly, dried...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com