Semiconductor device and manufacturing method

A manufacturing method and semiconductor technology, applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve the problems of not being practical, increasing costs, dislocations, etc., and achieve the effect of excellent drain current characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Hereinafter, examples of the present invention will be described. In addition, this invention is not limited to the following Example, It can apply to another aspect.

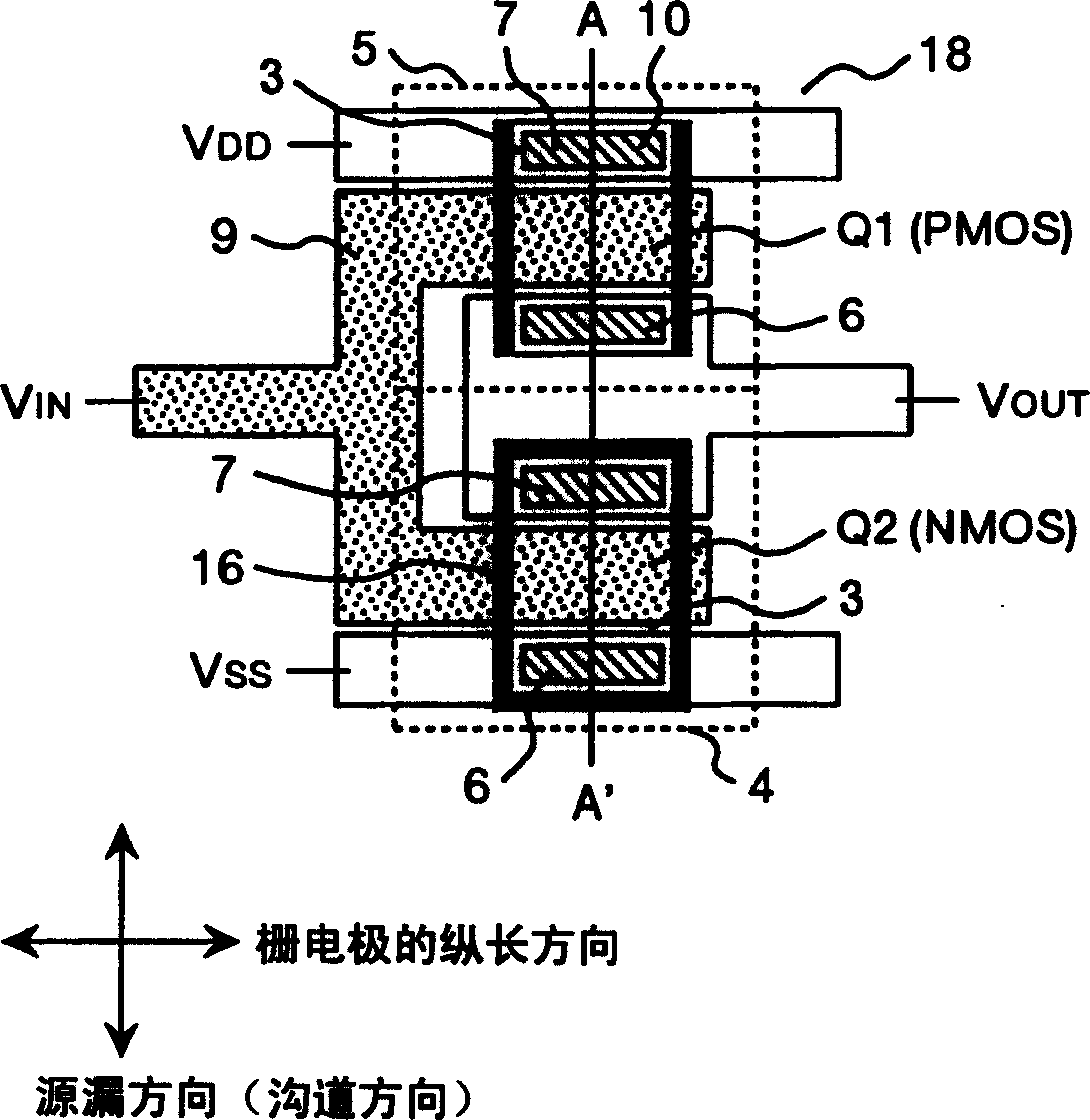

[0049] use below figure 1 The first embodiment of the present invention will be described. figure 1 is the inverter circuit diagram of this embodiment, figure 2 It is a layout diagram. image 3 yes means figure 1 Sectional view of A-A'.

[0050] like figure 2 As shown, the present embodiment has a p-channel field effect transistor Q1, an n-channel field effect transistor Q2, and wirings electrically connecting these transistors.

[0051] The n-channel type field effect transistor Q2 formed on the substrate (sub1) 1 consists of an n-type source (soce1) 6, a drain (drain1) 7, and a gate electrode formed on a p-type well layer (pwell) 4. (poly-Si) 9, gate oxide film (gato-ox) 8. And the p-channel type field effect transistor Q1 is formed on the n-type well layer (pwell) 5 by the p-type source (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com