Polymer emulsion for cement base material water reducing and its preparing method

A technology of polymer emulsion and cement-based material, applied in the field of polymer emulsion, can solve the problems of high water absorption, reducing the water resistance of polymer emulsion-modified cement-based materials, and increasing the fluidity of modified cement-based materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

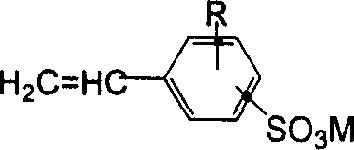

[0041] Embodiment 1: the preparation of polymer emulsion of the present invention

[0042] Methoxylated polyethylene glycol methacrylate (number average molecular mass M n =1000) 5g, methoxylated polypropylene glycol polyethylene glycol methacrylate (M n =2000) 5g, polyethylene glycol methacrylate (M n =5000) 5g, methyl methacrylate 5g, butyl acrylate 45g, sodium styrene sulfonate 3g, sodium vinyl sulfonate 2g, styrene 30g, mix well, put into 200g of water under stirring, vigorously stir to make it emulsified. Then put 1 / 5 of the emulsion into the three-necked bottle, add 0.25g of ammonium persulfate initiator, raise the temperature to 70-72°C, and keep warm until the material turns blue. At this time, an exothermic peak will appear, and the temperature may rise to 80°C. ℃ or more. After the temperature drops, add the remaining emulsion and 0.25 g of the remaining initiator dropwise, and control the temperature in the bottle to stabilize at 70-75°C. Vacuumize to remove unr...

Embodiment 2

[0043] Embodiment 2: the preparation of polymer emulsion of the present invention

[0044] Polypropylene glycol polyethylene glycol methacrylate (M n =2000) 10g, polyethylene glycol acrylate (M n =4000) 5g, methyl methacrylate 25g, butyl acrylate 47g, ethyl methacrylate 6g, methacrylic acid 2g, trifluoroethyl methacrylate 3g, 2-acrylamido-2-methylpropanesulfonate Mix 2g of acid (AMPS) evenly, put it into 200g of water under stirring, and stir vigorously to emulsify it. Then put 80g of emulsion into a three-necked bottle, add 0.35g of potassium persulfate initiator, raise the temperature to 72-75°C, keep warm until the material turns blue, and control the temperature at about 80°C when the reaction exotherms. After the temperature drops, add the remaining emulsion and 0.35 g of the remaining initiator dropwise, and control the temperature in the bottle to stabilize at 70-75°C. Vacuumize to remove unreacted monomers, and finally cool down, and add ammonia water to adjust the ...

Embodiment 3

[0045] Embodiment 3: the preparation of polymer emulsion of the present invention

[0046] Polyethylene glycol acrylate (M n =4000) 8g, polytetramethylene glycol methacrylate (M n =2000) 4g, methoxylated polyethylene glycol methacrylate (M n =8000) 8g, methyl methacrylate 5g, butyl acrylate 7g, N-methylol acrylic acid amine 2g, polyethylene glycol methylene succinate butylsulfonate sodium 5g, methoxylated polyethylene glycol Alcohol (polymerization degree m=10) 5 g of sodium maleate hexadecyl sulfonate, 55 g of vinyl acetate, and 1 g of methylene succinic acid were evenly mixed, and were thrown into 200 g of water under stirring, and vigorously stirred to make it emulsified. Then put 50g of the emulsion into a three-necked flask, add 0.25g of potassium persulfate initiator, and raise the temperature to 75°C for polymerization. When there is no obvious reflux in the condenser, drop the remaining emulsion and 0.6 g of the remaining initiator within 2 to 2.5 hours, keep warm f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com