Polymer processing aid and method for processing polymers

一种加工助剂、聚合物的技术,应用在体融加工各种高聚物的助剂和加工领域,能够解决聚合物的方法和助剂组合物未满足等问题,达到消除薄膜条纹现象、减少浑浊、减少或消除口型泄漏的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

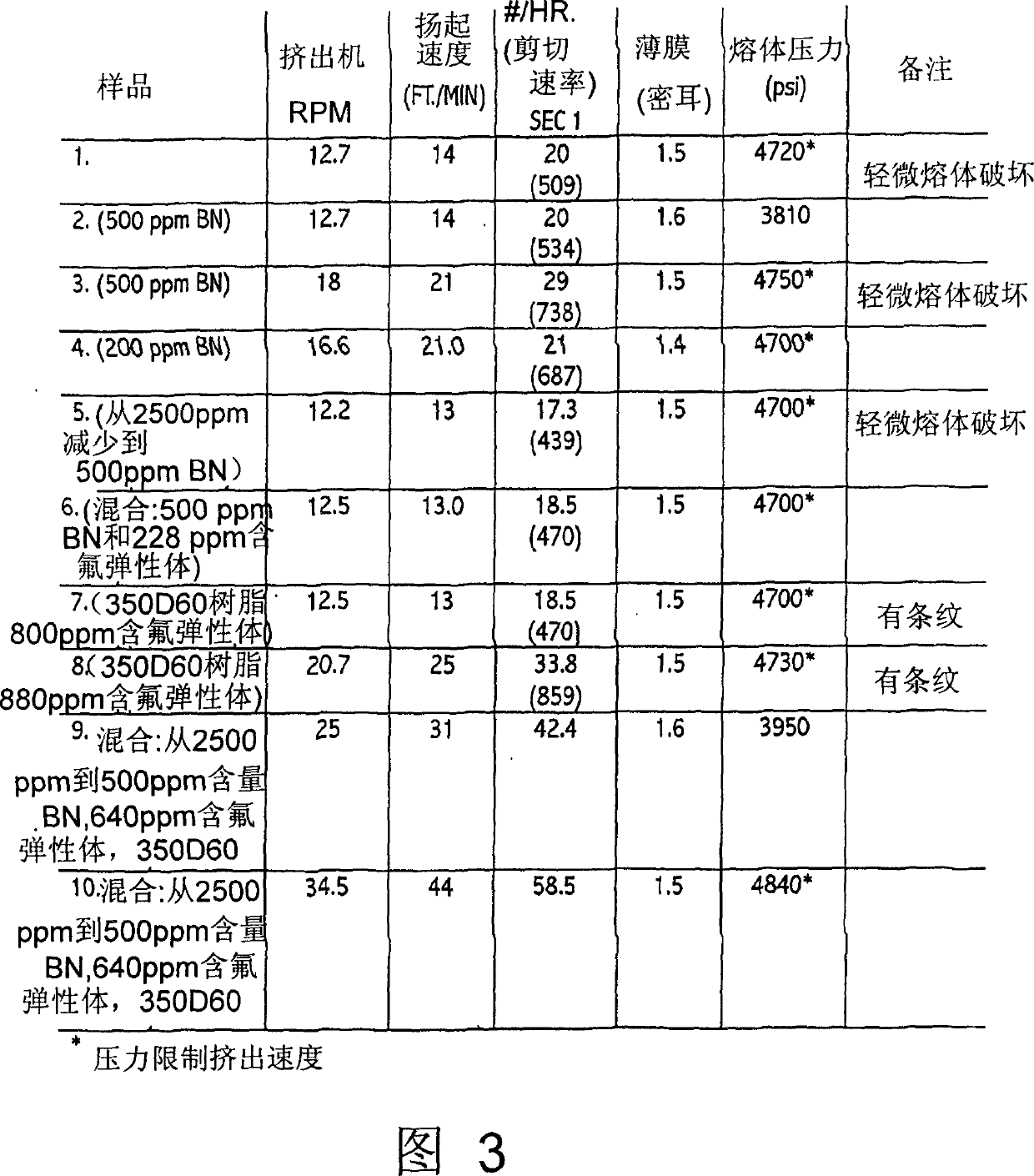

[0060] The following examples will provide further guidance to those skilled in the art in the practice of the invention. The examples provided are merely representative of those which assist in the practice of the invention. Accordingly, these examples are not intended to limit the invention as defined by the appended claims.

[0061] General steps for masterbatch preparation

[0062] Both the fluoroelastomer and the boron nitride were mixed in powder form in a suitable ratio in a V-type mixer with reinforcing rods at 10 revolutions per minute. The fluoroelastomer / BN mixture is then mixed with polyethylene, preferably also in powder form. After mixing in a suitable mixer, it is melted and extruded to form pellets of various sizes.

[0063] The extrusion operation was carried out in a single-pass Farrell mixer, followed by a melt extrusion pelletization process. Alternatively, the extrusion operation can be carried out together with the pelletizing process in a twin-screw ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com