Welded steel pipes with ribs and method of manufacture

A technology for welding steel pipes and manufacturing methods, applied in the direction of tubular elements, lighting and heating equipment, heat exchange equipment, etc., can solve the problems of inability to adopt processing technology, unfavorable cleaning and cleaning of oil dirt, reduce the range of rib areas, etc., and achieve width and dimension accuracy Easy to control, basically consistent heat transfer efficiency, easy to clean and clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the drawings and specific embodiments.

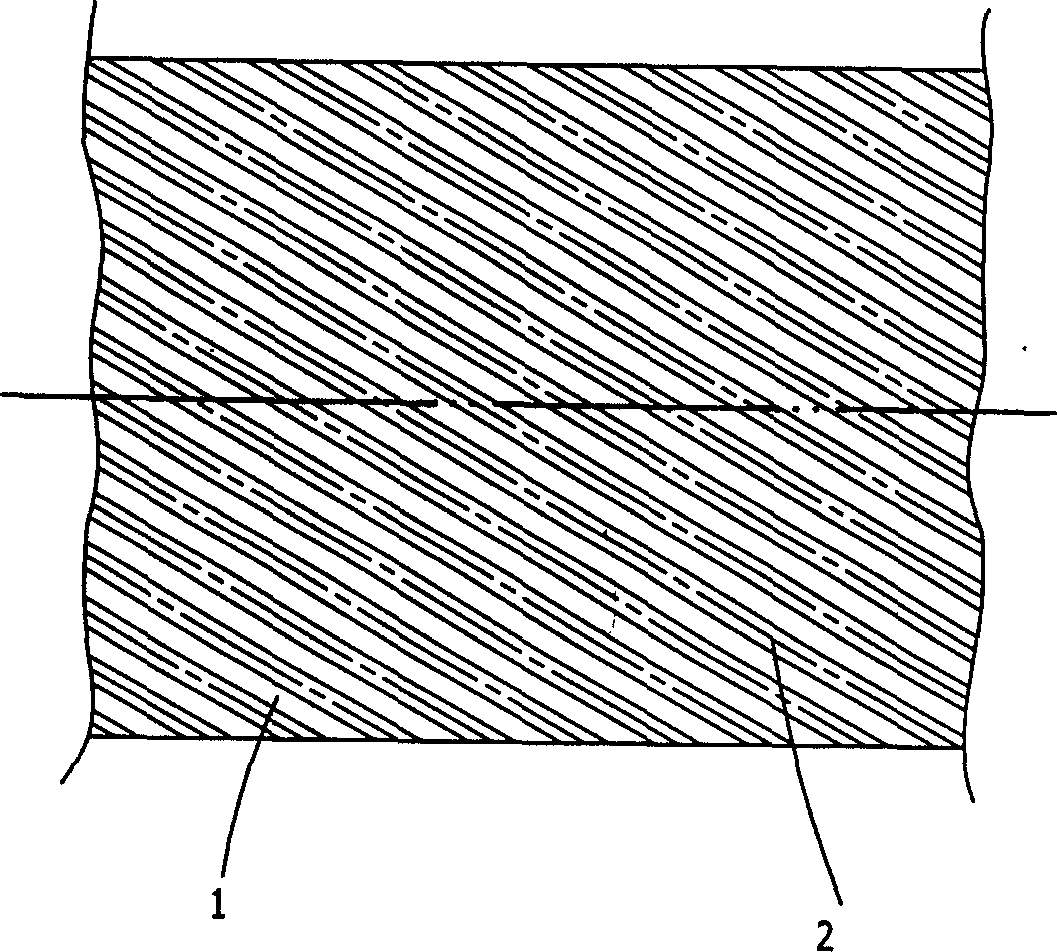

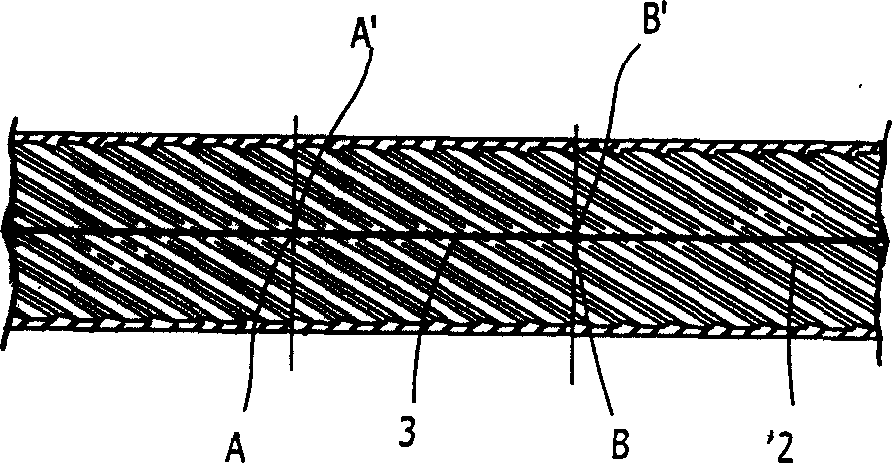

[0035] Figure 1~7 The shown finned welded steel pipe with low cost but improved heat conduction efficiency and its manufacturing method are one of the embodiments of the present invention. The finned welded steel pipe is actually formed on the basis of Bondi pipe It is formed by bending and welding steel strips that have been rolled, sheared and heat-treated. The welding seam is parallel to the longitudinal axis of the steel pipe. There are multiple convex spiral ribs 2 on the wall of the steel pipe 1. These The fins form a certain angle with the longitudinal axis of the steel pipe, that is, the spiral angle, and are parallel and continuously distributed. The cross-sectional shape of the fins is triangular. They are butted with the corresponding fins at the steel pipe welding seam to form a complete spiral rib. Among them, the outer diameter of the steel pipe is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com