Preparation method for reinforced aluminum base composite material composed by in situ alpha-Al2O3 crystal whisker and TiC grain

An aluminum-based composite material and particle compounding technology, which is applied in the field of preparation of in-situ α-Al2O3 whiskers and TiC particle composite reinforced aluminum-based composite materials, can solve the problems of backward development speed, high cost, complicated process technology, etc., and achieve The effect of low cost, small size and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

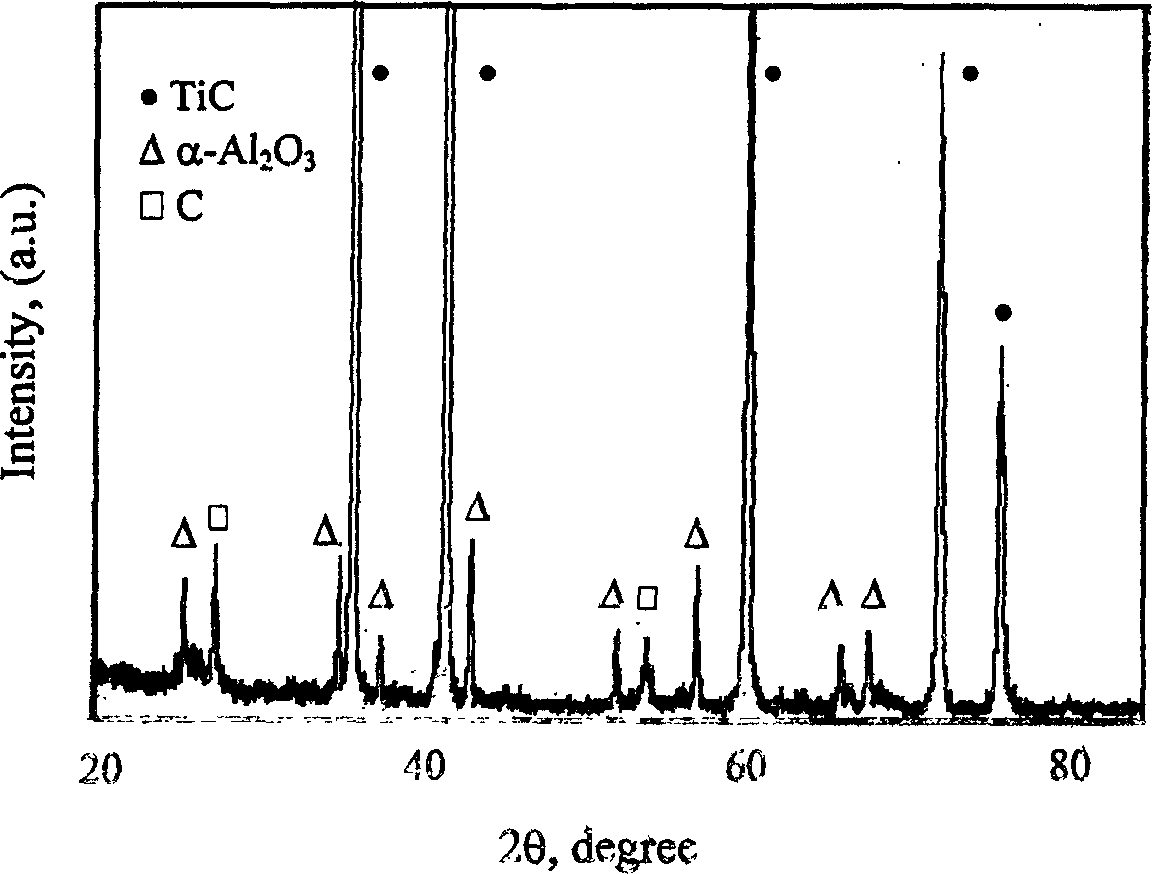

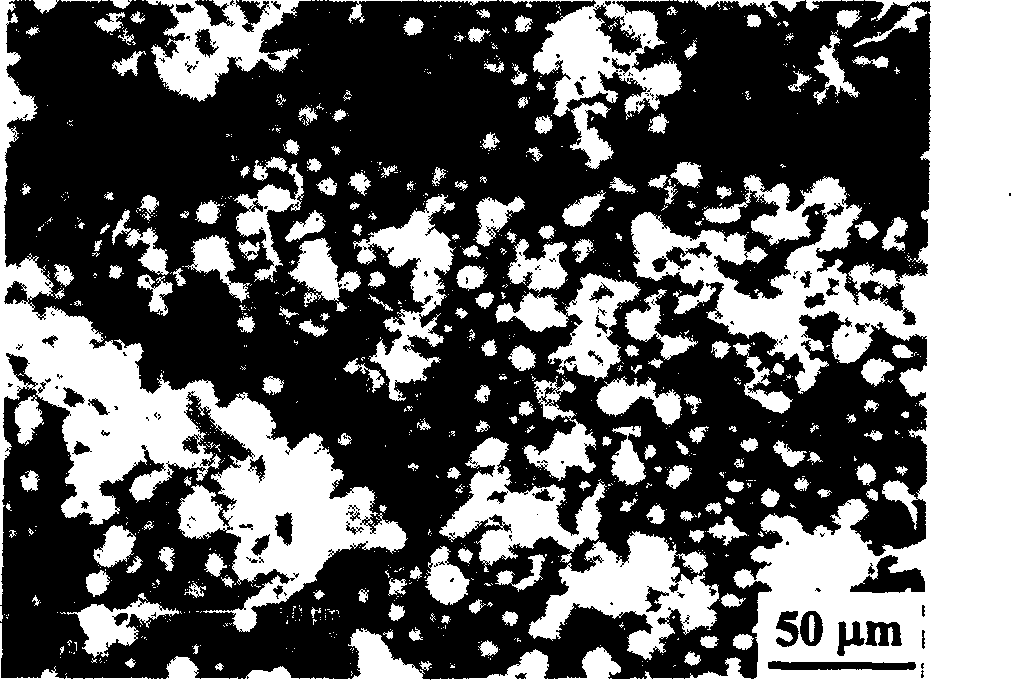

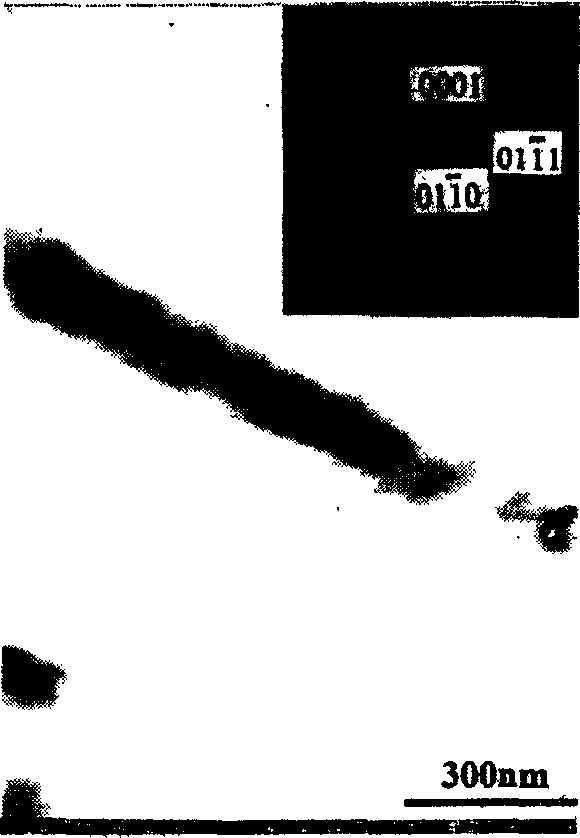

Embodiment 1

[0042] Preparation of 0.3% α-Al 2 o 3 Whiskers (calculated. % by weight) and 3% by weight TiC / technically pure aluminum composite. Weigh Al powder, Ti powder and C powder with purity of 98%, 99.8% and 99.5% and particle size of 75 μm, 45 μm and 10 μm according to the ratio of Al:Ti:C=2:70:28, and mix them evenly . A cylindrical prefabricated block of Φ20×30mm is pressed on a 50-ton press. Put 2 kg of industrial pure aluminum into an intermediate frequency induction furnace to melt and heat to 850°C. Press 0.06 kg of prefabricated blocks into molten aluminum with a graphite bell jar and keep warm for 10 minutes. When the temperature drops to 750° C., add 0.4 wt % hexachloroethane for refining. When the melt temperature is 720°C, it is poured into a metal mold to obtain 0.3 wt% α-Al 2 o 3 Whiskers and 3 wt% TiC / commercially pure aluminum composites. Composite material σ b is 147MPa, and δ is 14%.

Embodiment 2

[0044] Preparation of 0.45% α-Al 2 o 3 Whiskers (calculated. % by weight) and 5% by weight TiC / Al-21Si-2.5Cu composite. By Al:TiO 2 : C = 1: 2.22: 0.33 ratio to take appropriate amounts of Al powder, TiO with a purity of 98%, 99.8% and 99.5% and a particle size of 75 μm, 75 μm and 10 μm respectively 2 powder and C powder, mix them well. A cylindrical prefabricated block of Φ20×30mm is pressed on a 50-ton press. Put 4 kg of Al-21Si-2.5Cu alloy into a medium-frequency induction furnace to melt and heat to 950 °C. Press a 0.20 kg prefabricated block into molten aluminum with a graphite bell jar and keep it warm for 15 minutes. Refining is added by adding 0.3% by weight of hexachloroethane to the melt. When the temperature drops to 740°C, add 0.4% hexachloroethane to the weight of the melt for refining. When the melt temperature is 730°C, it is poured into a metal mold to obtain 0.45 wt% α-Al 2 o 3 Whiskers and 5 wt% TiC / Al-21Si-2.5Cu composites. Composite material σ b ...

Embodiment 3

[0046] Preparation of 0.5% α-Al 2 o 3 Whiskers (calculated. wt%) and 5 wt% TiC / 7075 composite. By Al:TiO 2 : Ti: C=1: 2.6: 0.44: 0.44 The ratio of weighing appropriate amount of purity is respectively 98%, 99.8% and 99.5%, the particle size is respectively 75 μm, 75 μm, 45 μm and 10 μm of Al powder, TiO 2 Powder, Ti powder and C powder, mix them evenly. A cylindrical prefabricated block of Φ20×30mm is pressed on a 50-ton press. Put 4 kg of 7075 alloy into an intermediate frequency induction furnace to melt and heat to 900°C. Press a 0.20 kg prefabricated block into molten aluminum with a graphite bell jar and keep it warm for 10 minutes. Refining by adding 0.3% hexachloroethane by weight of the melt. When the melt temperature is 730°C, it is poured into a metal mold to obtain 0.5 wt% α-Al 2 o 3 Whiskers and 5 wt% TiC / 7075 composite. Composite material σ after extrusion b It is 675MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com