Internal combustion engine homogeneous pressure combustion system capable of directly controlling igniting time

A technology of homogeneous compression ignition and ignition timing, applied in electrical control, engine control, fuel injection control, etc., can solve the problem of narrow application range of CAI combustion process conditions, insufficient control of lean mixture ignition timing, control accuracy and flexibility gender issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

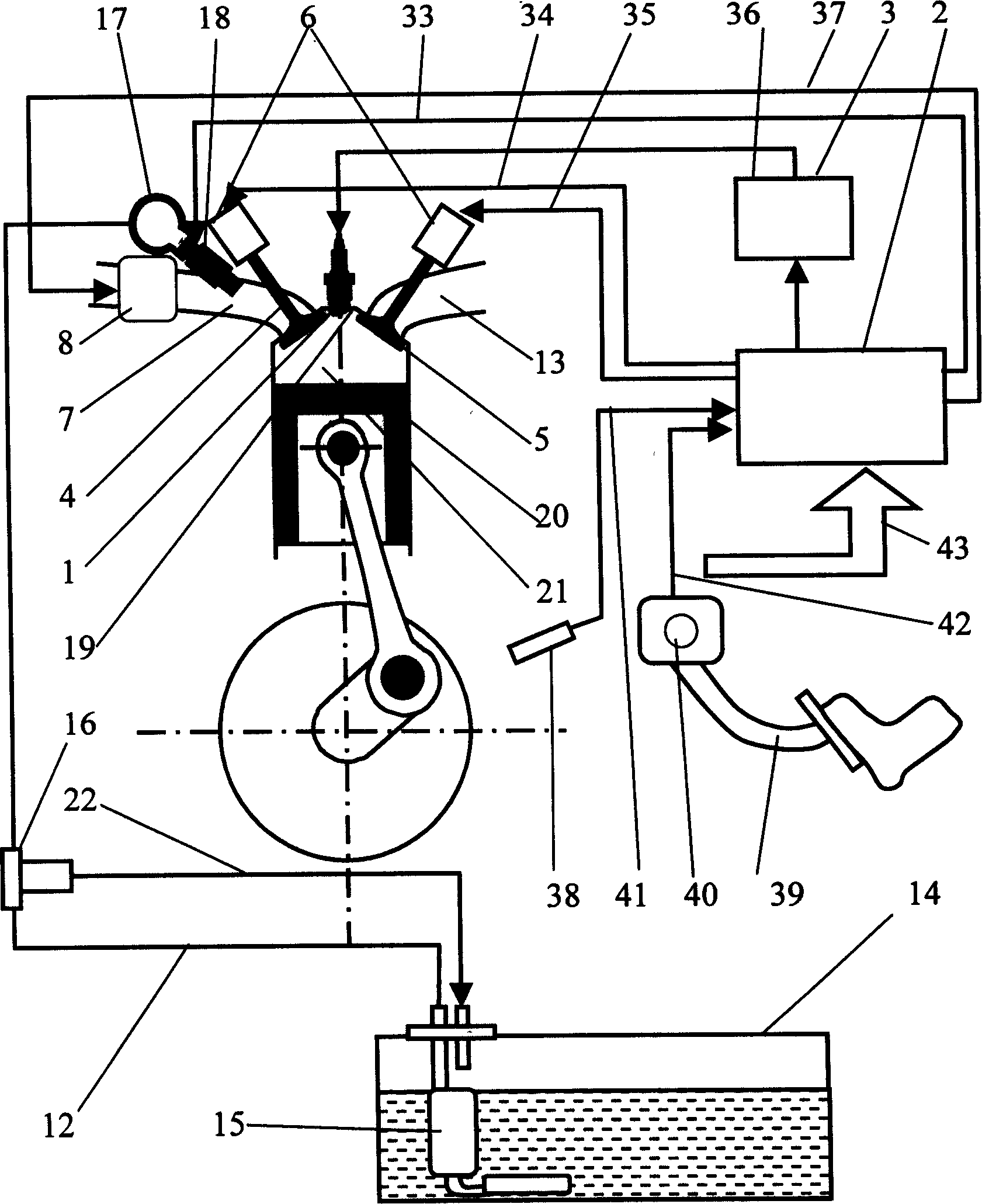

[0008] Such as figure 1 As shown, the homogeneous compression ignition combustion system of an internal combustion engine that can directly control the ignition moment includes five parts: gas distribution system, fuel injection system, ignition system, combustion chamber 21, and electronic control unit 2.

[0009] Among them, the function of the gas distribution system is to quantitatively provide the required air to the engine cylinder, and realize the internal exhaust gas recirculation (EGR) according to the need, so as to achieve the purpose of increasing the temperature of the mixture in the cylinder. The system includes an electronic throttle body 8 , an intake port 5 , an intake valve 4 connected in sequence, and an exhaust valve 5 and an exhaust port 13 connected in sequence. On the upper ends of the intake valve 4 and the exhaust valve 5 are two variable valve timing drivers 6, which can adopt electro-hydraulic drive mechanisms or other known forms. The electronic th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com