Autombobile windshield glass possessing infrared reflection performance and its preparation method

A windshield and infrared reflection technology, applied to windshields, vehicle parts, windows, etc., can solve the problem of low transmittance of visible light and achieve the effect of ensuring clarity and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

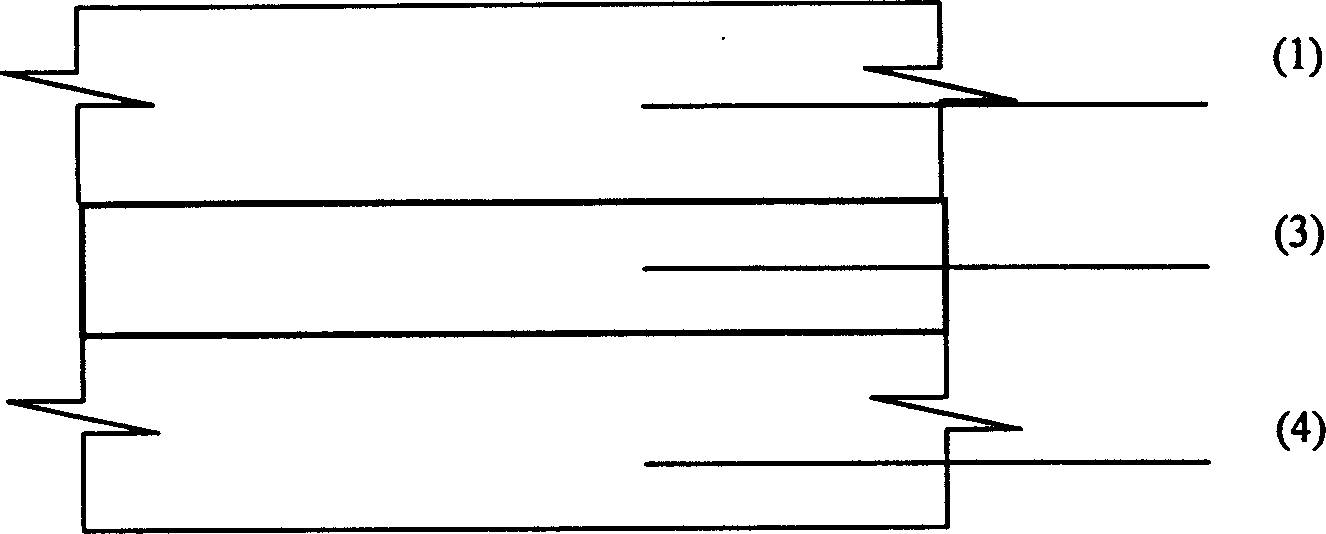

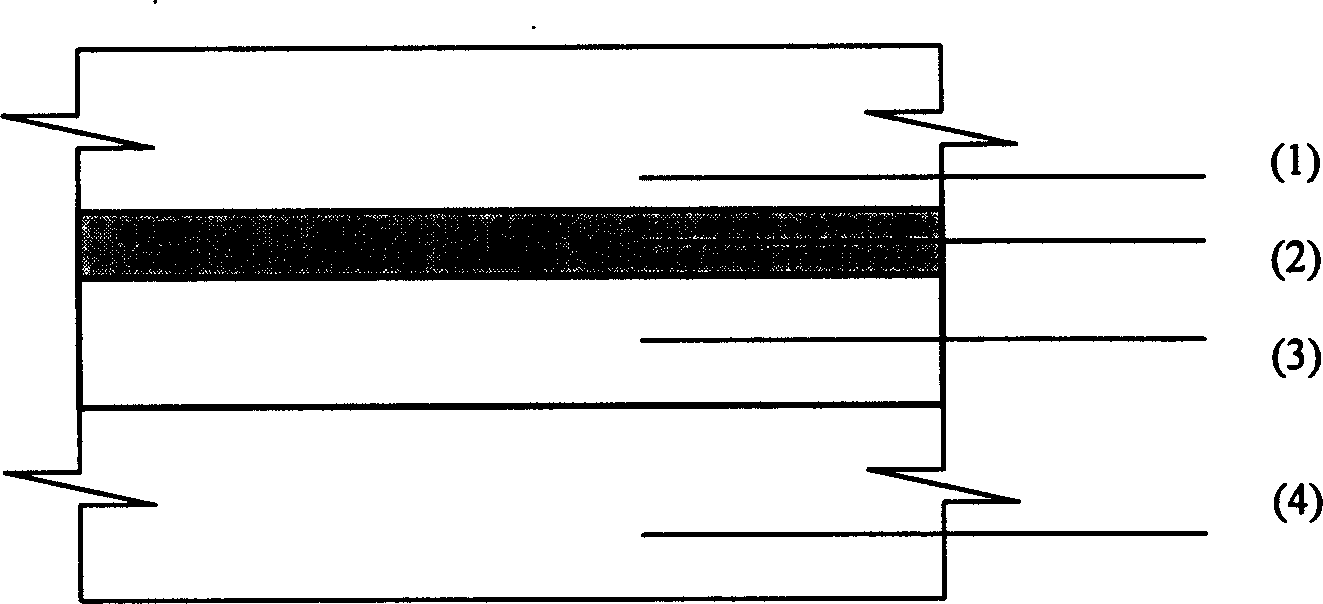

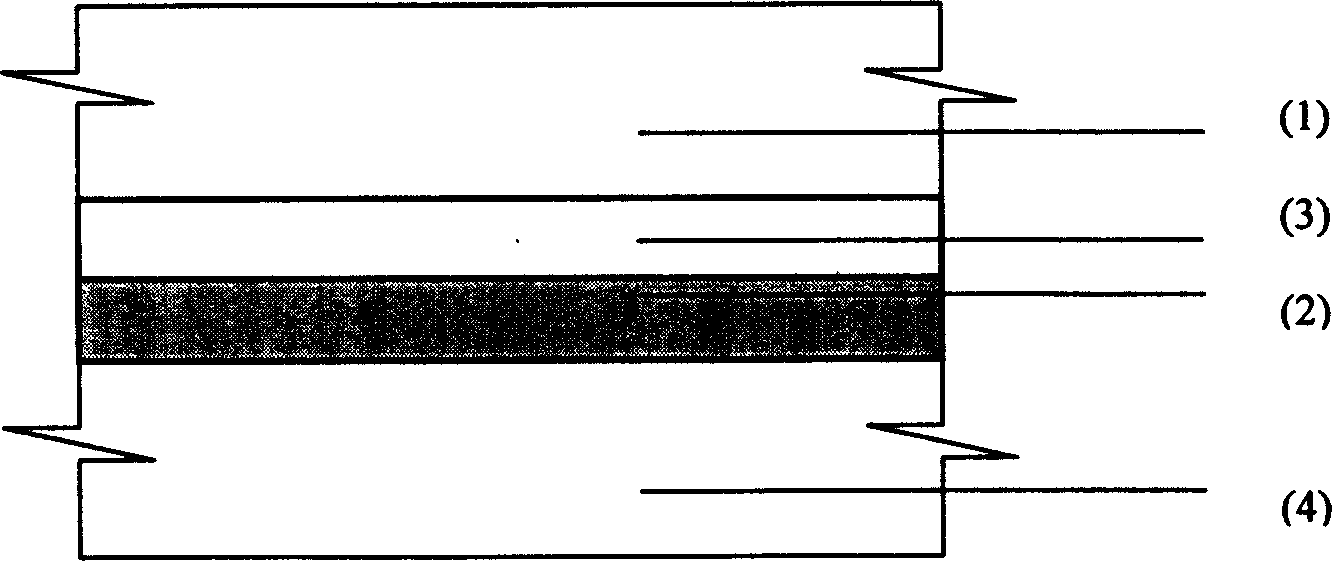

[0021] Using an indium tin oxide ceramic target containing 10% tin oxide as a raw material, a magnetron sputtering method is used to deposit an indium tin oxide film on the inner surface of a 3 mm thick hot-bending glass as the outer glass, and the sputtering process is the working Air pressure 1.5Pa, background vacuum 3.0×10 -3 Pa, the voltage is 350V. The frequency of the medium frequency AC arc suppression power supply is 60KHz, and the glass temperature is 350°C. A 350 nm thick indium tin oxide film was deposited. Then it is packaged together with 0.8mm thick PVB film and 4mm thick hot bending glass as figure 2 A car windshield of the structure shown. Install the car windshield on a car. Under the condition of the outside temperature of 35°C, the car is parked still in a place directly exposed to the sun. After turning off the power for 1 hour, the temperature inside the car with the ordinary car windshield installed reaches 67°C. And the car interior temperature that...

Embodiment 2

[0023] Use a zinc-aluminum oxide ceramic target material containing 2.0% aluminum oxide to deposit a zinc-aluminum oxide film on one side of a 0.8mm thick PVB film by sputtering. The sputtering process is a working pressure of 2.0Pa and a background vacuum of 0.8×10 -3 Pa, the voltage is 350V. The frequency of the intermediate frequency AC arc suppression power supply is 25KHz, and the PVB film is at room temperature. A zinc-aluminum oxide film with a thickness of 350 nm was deposited. Then it is packaged together with 3mm thick hot bending glass (outer layer) and 4mm thick hot bending glass (inner layer) as figure 2 A car windshield of the structure shown. Install the car windshield glass on a car. Under the condition of the outside temperature of 35°C, the car is parked still in a place directly exposed to the sun. After turning off the power for 2 hours, the temperature inside the car with the ordinary car windshield glass installed reaches 67°C. And the car interior te...

Embodiment 3

[0025] Zinc oxide silicon ceramic target material containing 1.5% silicon oxide is used to deposit zinc oxide silicon film on 3mm thick hot bending glass by sputtering method. The sputtering process is working pressure 2.5Pa, background vacuum 4.0×10 -3 Pa, the voltage is 370V. The frequency of the medium frequency AC arc suppression power supply is 30KHz, and the glass temperature is 100°C. A zinc oxide silicon film with a thickness of 300 nm was deposited. Then it is packaged together with 0.8mm thick PVB film and 4mm thick hot bending glass as figure 2 A car windshield of the structure shown. Install the car windshield glass on a car. Under the condition of the outside temperature of 35°C, the car is parked still in a place directly exposed to the sun. After turning off the power for 2 hours, the temperature inside the car with the ordinary car windshield glass installed reaches 67°C. And the car interior temperature that has installed the automobile windshield glass of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com