Preparing method of integrated capillary electrophoresis electrochemical luminescence detecting chip

A technology of capillary electrophoresis and luminescence detection, which is applied in the direction of optomechanical equipment, electric excitation analysis, photoplate making process of patterned surface, etc., can solve the problems of cumbersome operation process, time-consuming, high equipment requirements, etc., and achieve convenient use, simple production, Inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

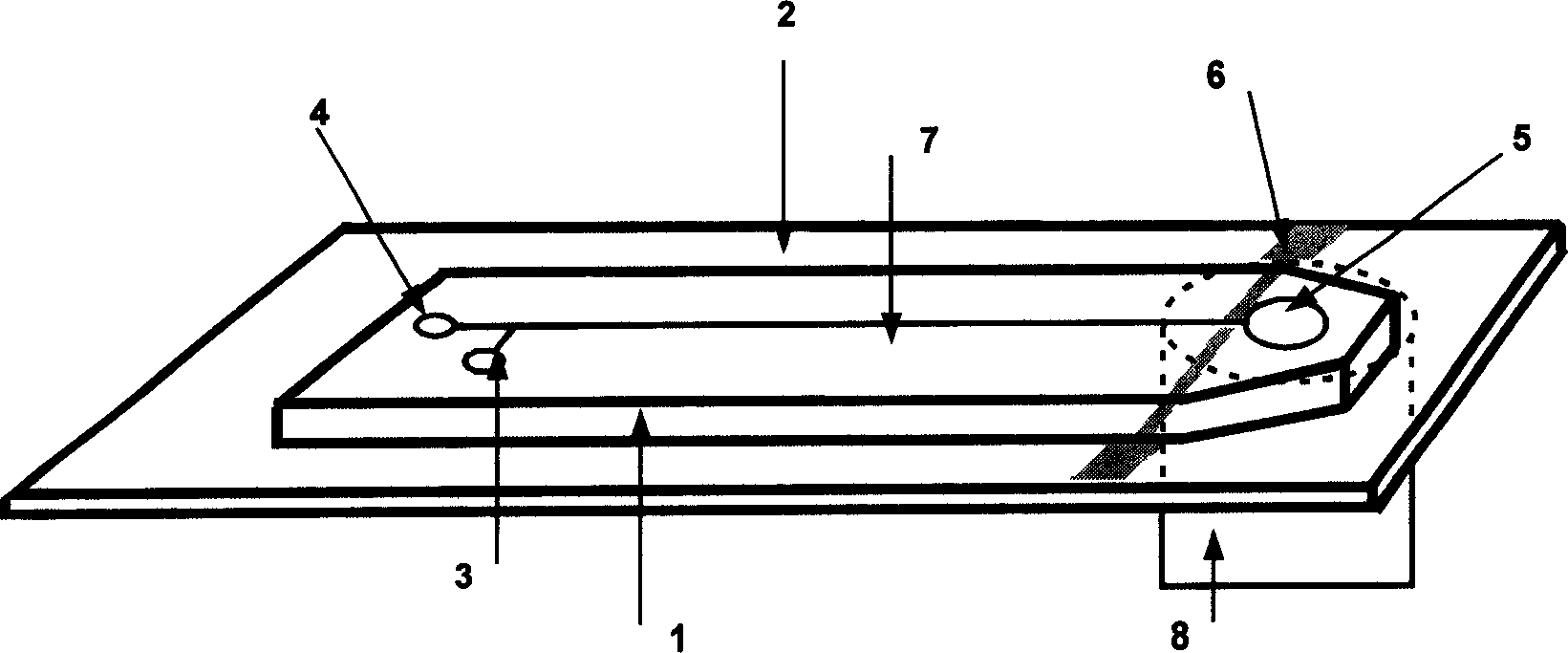

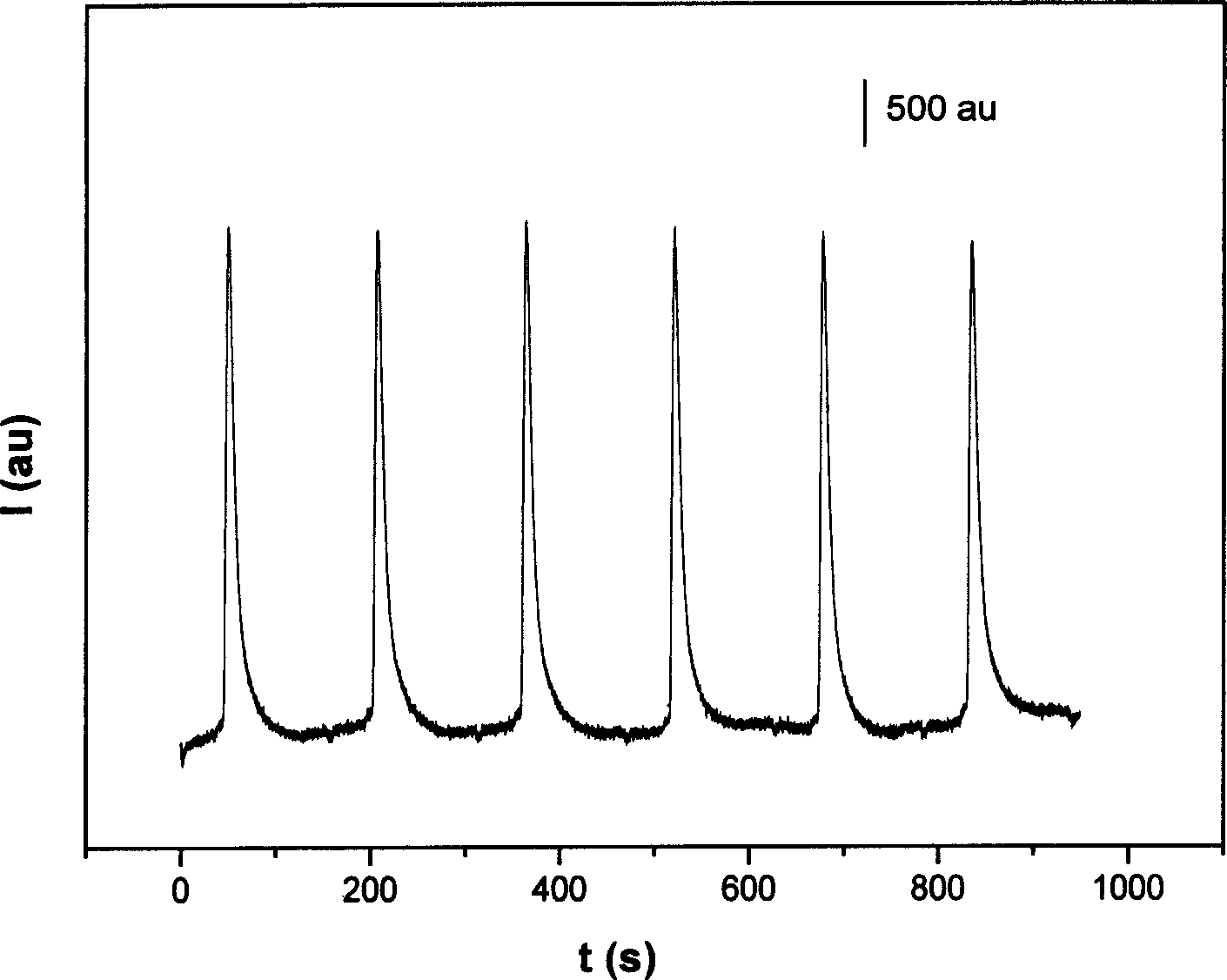

[0018] Embodiment 1: The mask required for photolithography is a transparent film with a channel pattern output by a high-definition 3000dpi laser printer. Covered on the chrome plate glass coated with photoresist, exposed by ultraviolet light, then developed with developer and removed the chrome layer, cleaned, placed in 1.7%: 1.3% HF / NH 4 In the F glass etching solution, the exposed glass part is etched for 15 minutes, and after the etching is completed, the excess photoresist and the chromium layer are removed with 2% sodium hydroxide solution. Wash the glass template and let it dry. The PDMS monomer and curing agent were mixed at a ratio of 10:1, degassed by a vacuum pump, then poured on a glass template, and heated in an oven at 60°C for 2 hours to cure. After being fully cured, the PDMS layer is peeled off from the glass template, and then the PDMS is cut into the desired chip shape with a blade. The liquid pool of the chip is made by punching holes in the PDMS layer w...

Embodiment 2

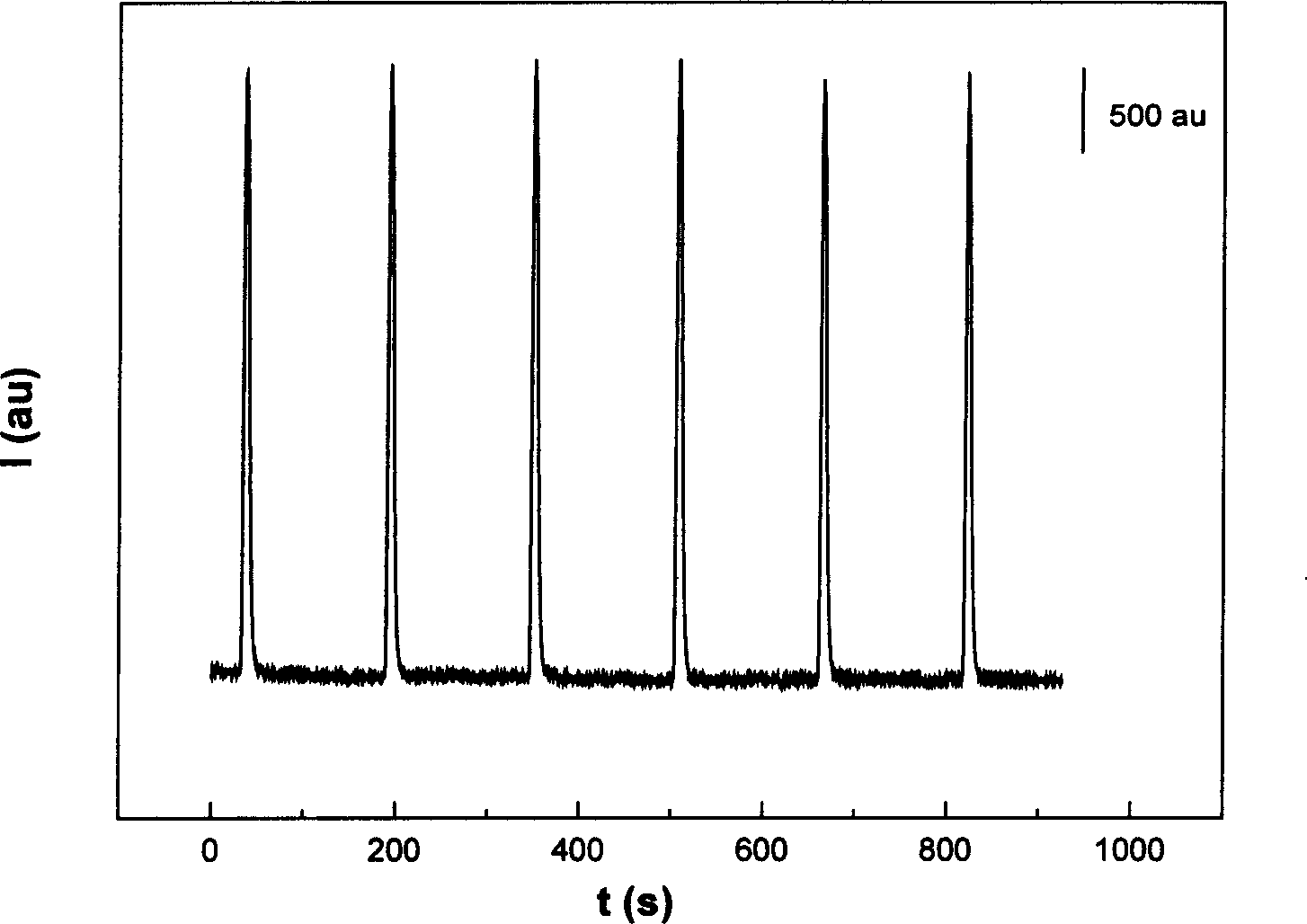

[0022] Embodiment 2: The mask required for photolithography is a transparent film with a channel pattern output by a high-definition 3000dpi laser printer. Covered on the chrome plate glass coated with photoresist, exposed by ultraviolet light, then developed with developer and removed the chrome layer, cleaned, placed in 1.7%: 1.3% HF / NH 4In the F glass etching solution, the exposed glass part was etched for 20 minutes, and after the etching was completed, the excess photoresist and the chromium layer were removed with 2% sodium hydroxide solution. Wash the glass template and let it dry. The PDMS monomer and curing agent were mixed at a ratio of 10:1, degassed by a vacuum pump, then poured on a glass template, and heated in an oven at 70°C for 1.5 hours to cure. After being fully cured, the PDMS layer is peeled off from the glass template, and then the PDMS is cut into the desired chip shape with a blade. The liquid pool of the chip is made by punching holes in the PDMS lay...

Embodiment 3

[0026] Embodiment 3: The mask required for photolithography is a transparent film with a channel pattern output by a high-definition 3000dpi laser printer. Covered on the chrome plate glass coated with photoresist, exposed by ultraviolet light, then developed with developer and removed the chrome layer, cleaned, placed in 1.7%: 1.3% HF / NH 4 In the F glass etching solution, the exposed glass part was etched for 30 minutes, and after the etching was completed, the excess photoresist and the chromium layer were removed with 2% sodium hydroxide solution. Wash the glass template and let it dry. The PDMS monomer and curing agent were mixed at a ratio of 10:1, degassed by a vacuum pump, then poured on a glass template, and heated in an oven at 80°C for 1 hour to cure. After being fully cured, the PDMS layer is peeled off from the glass template, and then the PDMS is cut into the desired chip shape with a blade. The liquid pool of the chip is made by punching holes in the PDMS layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com