Fixed tube-sheet tubular heat exchanger detached to wash

A technology of tube-and-tube heat exchanger and fixed tube-sheet type, which is applied in the direction of fixed tubular conduit assembly, heat exchanger type, heat exchanger shell, etc., and can solve problems such as high sealing requirements, equipment cost limitation, and large tube spacing. Achieve the effect of reducing equipment consumables, improving utilization efficiency, and convenient disassembly and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

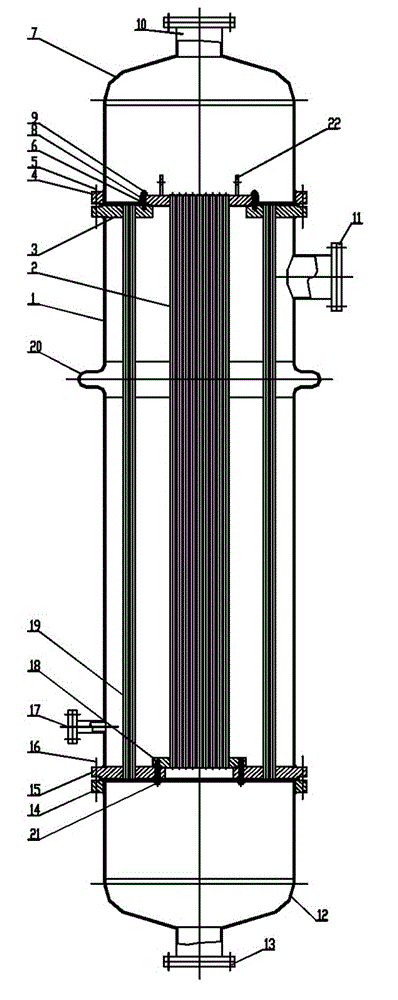

[0024] The present invention will be described in further detail below in conjunction with specific examples. It should be understood that these examples are for the purpose of illustrating the invention only and are not intended to limit the scope of the invention in any way. For simplicity of description, conventional nozzles, manholes, instrument interfaces, supports and other annexes are omitted in the description of the present invention, and those skilled in the art can design as required. Those skilled in the art can make many variations and improvements, such as adjusting the spout, and all these variations, adjustments, and improvements should be regarded as the scope of protection of the present invention.

[0025] Such as figure 1 As shown, the upper head 7 and the lower head 12 are respectively connected to the top and bottom of the cylinder 1 to form the heat exchanger body; plate 3 and the lower main tube plate 15, a certain number of upper secondary tube plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com