Concrete mortar spurting truck

A shotcrete truck and concrete technology, used in earth-moving drilling, wellbore lining, tunnel lining and other directions, can solve the problems of easy loosening of bolts, affecting the smoothness of pipelines, reducing the service life of components, etc., to improve the overall protection performance, easy Disassembly and cleaning, reducing the effect of elbow design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

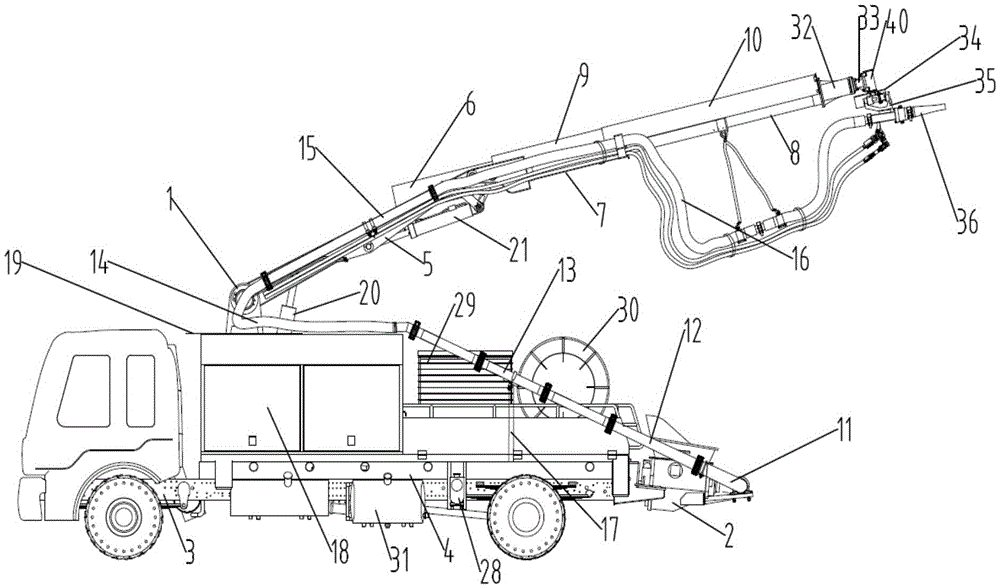

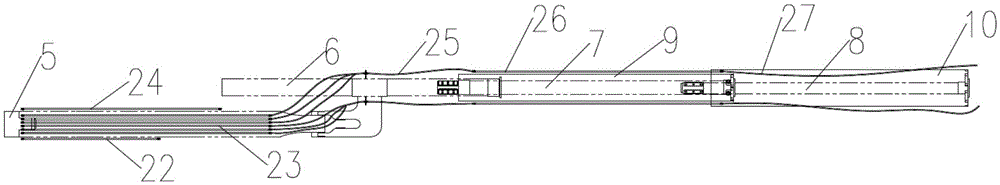

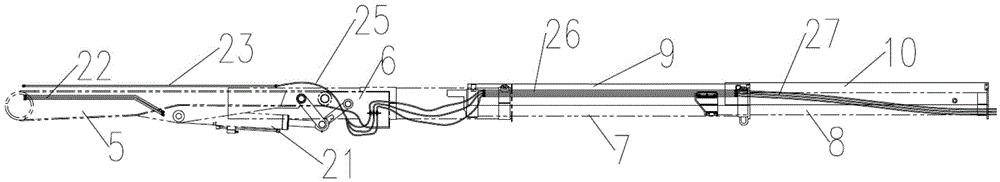

[0030] refer to figure 1 , this embodiment includes car body, slewing system, turntable 1, boom assembly, hydraulic system, pumping system 2, pump pipe assembly, quick-setting system, cleaning system, electrical system, air compressor system and nozzle assembly ;The car body includes chassis 3 and sub-frame 4; the hydraulic system is connected to the slewing system, the slewing system is connected to the turntable 1, the turntable 1 is connected to the boom assembly, and the boom assembly is connected to the nozzle assembly; The front part of the frame 4, the pumping system 2 is located at the rear of the sub-frame 4, the pumping system 2 is connected with the nozzle assembly through the pump pipe assembly; the air compressor system is connected with the nozzle assembly; the quick-setting system is connected with the nozzle assembly The assembly is connected; the electrical system is connected to the pumping system 2, the quick-setting system and the hydraulic system; the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com