Shell expansion type rock bolt

An expanding-shell, bolting technology, applied in the installation of bolts, construction, mining equipment, etc., can solve problems such as cracking, corrosion of steel bars, and limited length of bolts, and achieve simple construction technology, improved service life, and cost-effectiveness. superior effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

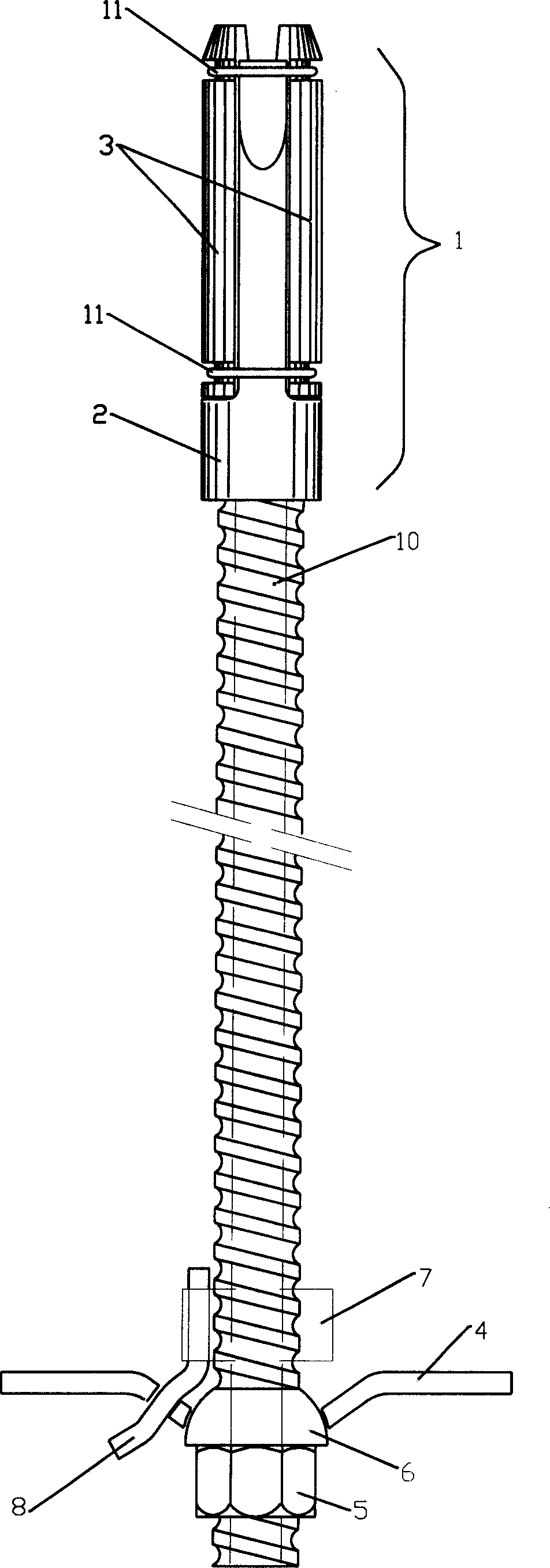

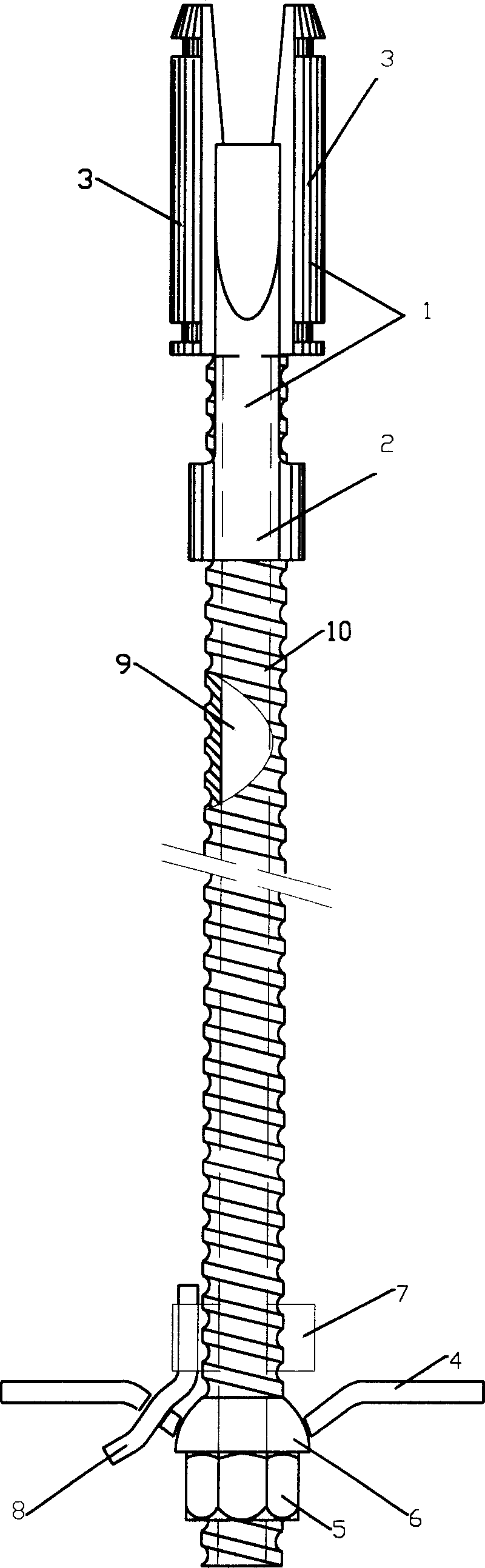

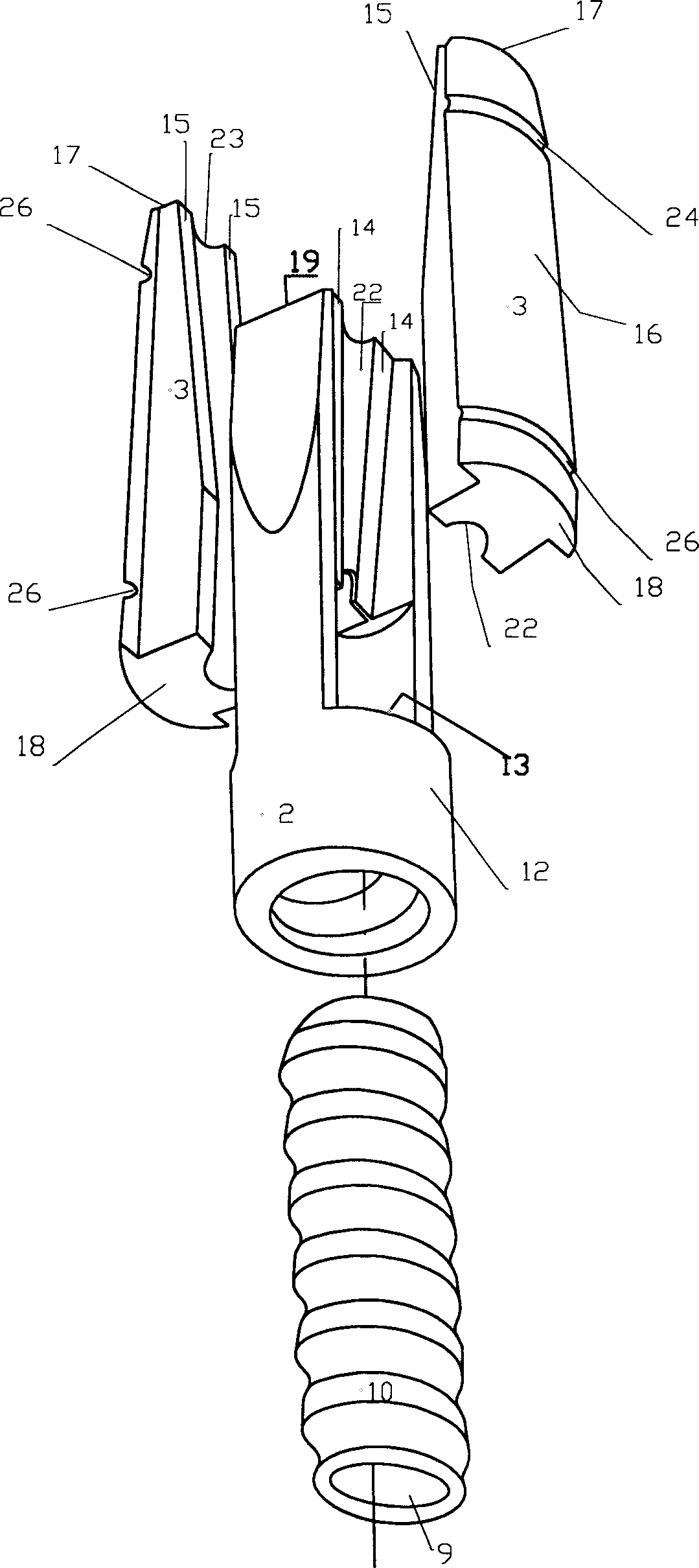

[0042] As shown in the figure, a shell-expanding anchor rod is composed of a shell-expanding anchor head 1, an anchor body 10, a support plate 4, a fastening nut 5, a washer 6, and a connecting pipe 8. The shell-expanding anchor head 1 is composed of Wedge 2 and two-petal expansion shell clips 3 are composed. The expansion shell clips 3 are fixed in the opening grooves 13 on both sides of the expansion shell inner wedge 2 through binding ropes 11. The lower part of the expansion shell inner wedge 2 is connected with the anchor rod body 10 Connection, both sides of the upper part are open grooves 13, and the middle part of the upper end of the open groove 13 has an inclined plane wedge 14, forming a double-sided wedge-shaped sliding groove 20; the inner side of the expansion shell clip 3 has an inclined plane 15 that matches the inclined plane wedge 14; the anchor rod body 10 After the top enters the inner wedge 2 of the expansion shell, it can cooperate with the lower end surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com