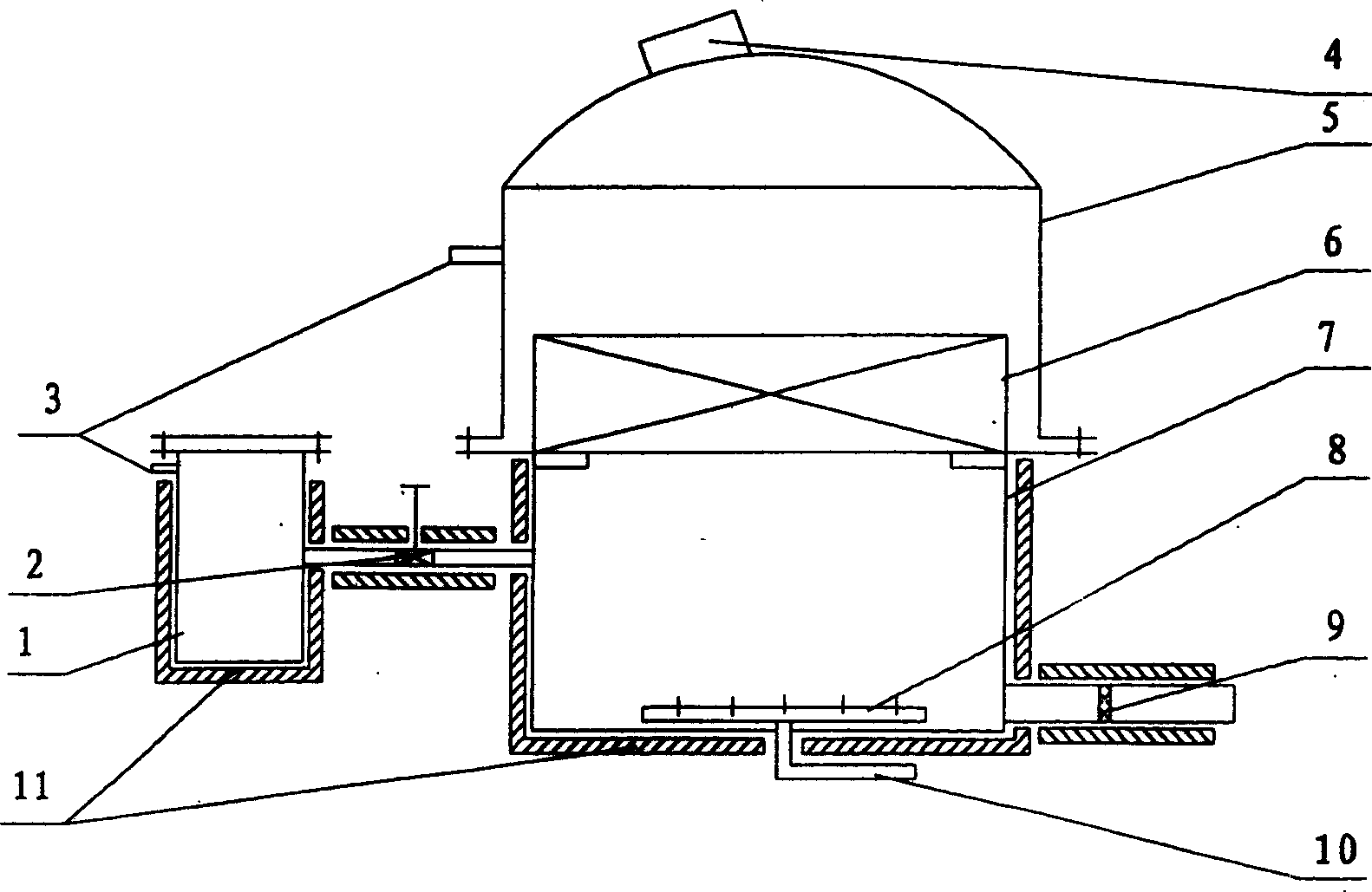

Method for removing sodium from coarse lithium by gas agitation under condition of vacuum, distillation at moderate temperature

A gas stirring and vacuum technology is applied in the field of gas stirring crude lithium vacuum medium temperature distillation and sodium removal, which can solve the problems of complex installation, high cost, complex production process, etc., and achieve the effects of simple process, high recovery rate and reasonable process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1. The furnace height is 1500mm, the diameter is Φ500mm, and the processing capacity is 20 kg / furnace; the inert gas distribution pipe is a straight pipe with a pipe diameter of Φ5mm, and the filter diameter is Φ50mm, and the thickness is 5mm. The crude lithium raw material has a sodium content of 0.7%, which is directly put into a vacuum furnace for melting, the distillation temperature is 440°C, the vacuum degree is 3Pa, filled with argon gas and stirred and distilled for 3 hours, the sodium content of the refined lithium is less than 0.005%, reaching Requirements for battery-grade lithium; the direct recovery rate is greater than 90%.

Embodiment 2

[0017] Embodiment 2: The furnace height is 1800mm, the diameter is Φ700mm, and the processing capacity is 70 kg / furnace; the inert gas distribution pipe is two rows of straight pipes, the pipe diameter is Φ8mm, the filter diameter is Φ60mm, and the thickness is 8mm. The crude lithium raw material has a sodium content of 1.0%. After melting, it is put into a vacuum furnace. The distillation temperature is 500° C., the vacuum degree is 3 Pa, and it is filled with argon gas to stir and distill for 5 hours. The sodium content of the refined lithium is less than 0.005%, reaching Requirements for battery-grade lithium; the direct recovery rate is greater than 90%.

Embodiment 3

[0018] Embodiment 3: The furnace height is 2000mm, the diameter is Φ1000mm, and the processing capacity is 100 kg / furnace; the inert gas distribution pipe is surrounded by a circle, the pipe diameter is Φ10mm, the filter diameter is Φ70mm, and the thickness is 10mm. The crude lithium raw material has a sodium content of 1.5%. After melting, it enters a vacuum furnace at a temperature of 440°C and a vacuum of 3 Pa. It is filled with argon and stirred and distilled for 8 hours. The sodium content of refined lithium is less than 0.005%, reaching battery grade. Lithium requirements; direct yields are greater than 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com