Method for heating acid washing solution

A heating method and pickling technology, which are used in the pickling process of hot-rolled strips in the cold rolling industry and the field of pickling solution heating, which can solve the problem of increasing the burden on the acid mist purification system, reducing the pickling speed, and corrosion of equipment and workshop steel structures. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

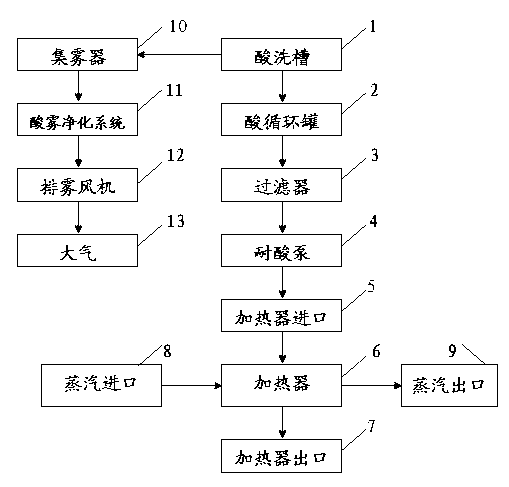

[0023] The pickling solution in the pickling tank 1 flows back to the acid circulation tank 2, and is filtered by the filter 3. The acid-resistant pump 4 pumps the pickling solution into the heater 6 through the heater inlet 5, and the heated pickling solution (90°C) passes through The heater outlet 7 is driven into the pickling tank 1 to form a cycle, and so on. The heating steam enters through the steam inlet 8 and is discharged from the steam outlet 9, so that the pickling solution always maintains the normal process temperature. The acid mist generated during the pickling process is concentrated by the mist collector 10 under the action of the mist exhaust fan 12, and the acid mist enters the acid mist purification system 11 for purification, and the mist exhaust fan 12 discharges the mist meeting the emission standard to the atmosphere 13.

[0024] Adoption of the present invention realizes heat exchange indirectly, does not dilute the pickling solution, and does not have...

Embodiment 2

[0028] A heating method for a pickling solution, characterized in that it proceeds in the following steps:

[0029] The pickling solution in the pickling tank 1 flows back to the acid circulation tank 2, and is filtered by the filter 3. The acid-resistant pump 4 pumps the pickling solution into the heater 6 through the heater inlet 5, and the heated pickling solution reaches 70°C. The heater outlet 7 enters the pickling tank 1 to form a cycle, and so on and on; the heating steam enters from the steam inlet 8 and is discharged from the steam outlet 9, so that the pickling solution always maintains the normal process temperature; the acid produced in the pickling process The mist is concentrated by the mist collector 10 under the action of the mist exhaust fan 12, and the acid mist enters the acid mist purification system 11 to be purified, and the mist exhaust fan 12 discharges the mist meeting the emission standard to the atmosphere 13.

Embodiment 4

[0031] A heating method for a pickling solution, characterized in that it proceeds in the following steps:

[0032] The pickling solution in the pickling tank 1 flows back to the acid circulation tank 2, and is filtered by the filter 3. The acid-resistant pump 4 pumps the pickling solution into the heater 6 through the heater inlet 5, and the heated pickling solution reaches 90°C. The heater outlet 7 enters the pickling tank 1 to form a cycle, and so on and on; the heating steam enters from the steam inlet 8 and is discharged from the steam outlet 9, so that the pickling solution always maintains the normal process temperature; the acid produced in the pickling process The mist is concentrated by the mist collector 10 under the action of the mist exhaust fan 12, and the acid mist enters the acid mist purification system 11 to be purified, and the mist exhaust fan 12 discharges the mist meeting the emission standard to the atmosphere 13.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com