Right-angle gear speed reducer

A gear reduction, orthogonal shaft technology, applied in the direction of gear transmission, belt/chain/gear, coupling, etc., can solve the problems of fretting wear, hindering the improvement of the durability of the reducer, and easily reducing the durability of shock loads. , to achieve the effect of improving impact resistance, sufficient durability, and preventing deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Embodiments of the present invention will be described below with reference to the drawings.

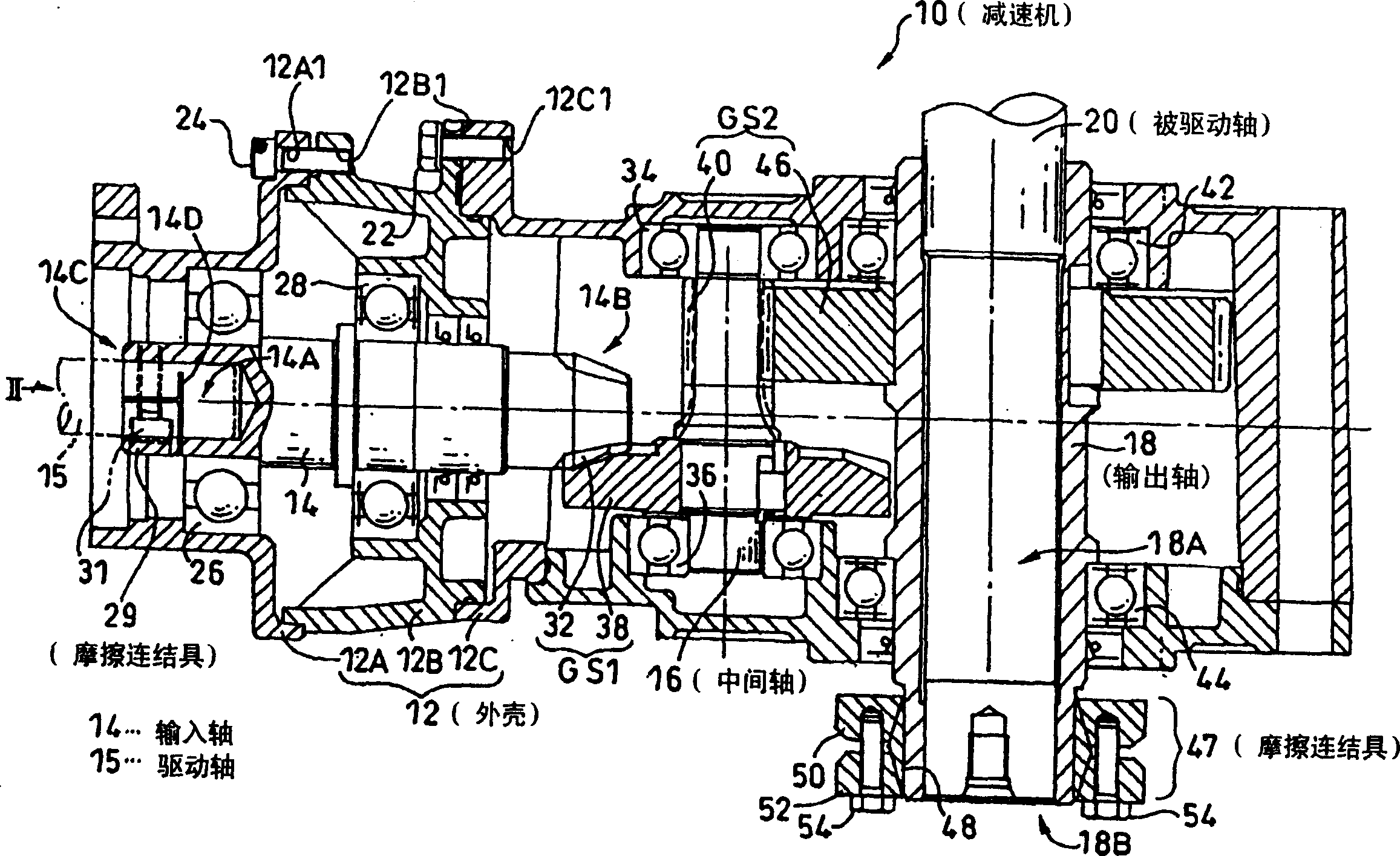

[0013] figure 1 It is a side sectional view of the orthogonal axis gear reducer 10 according to the embodiment of the present invention.

[0014] This orthogonal axis gear reducer 10 has a casing 12, and in the casing 12, an input shaft 14 arranged in the transverse direction in the drawing and an intermediate shaft 16 arranged in a direction perpendicular to the input shaft 14 are respectively provided. , and an output shaft 18 disposed parallel to the intermediate shaft 16 .

[0015] The housing 12 is composed of three first, second, and third housings 12A, 12B, and 12C. Bolt holes 12A1, 12B1, and 12C1 are respectively formed in the first to third casings 12A to 12C, and the first to third casings 12A to 12C can be connected to each other by a plurality of bolts 22, 24 (only a part is shown in the figure). combined.

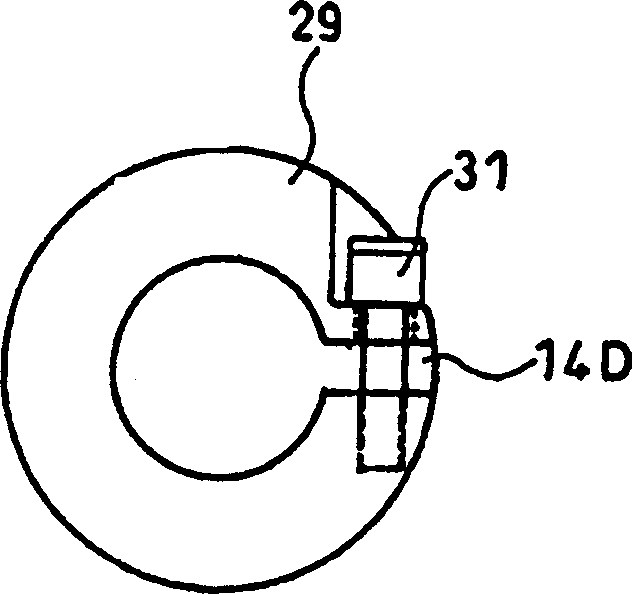

[0016] The input shaft 14 arranged in the housing 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com