10 nano-level gap electrode preparing method

A nanoscale, electrode technology, applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of easy to be affected by the external environment, unstable electrodes, unsuitable for industrial production, etc., to achieve easy control of parameters, nanometer The effect of stable electrode and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

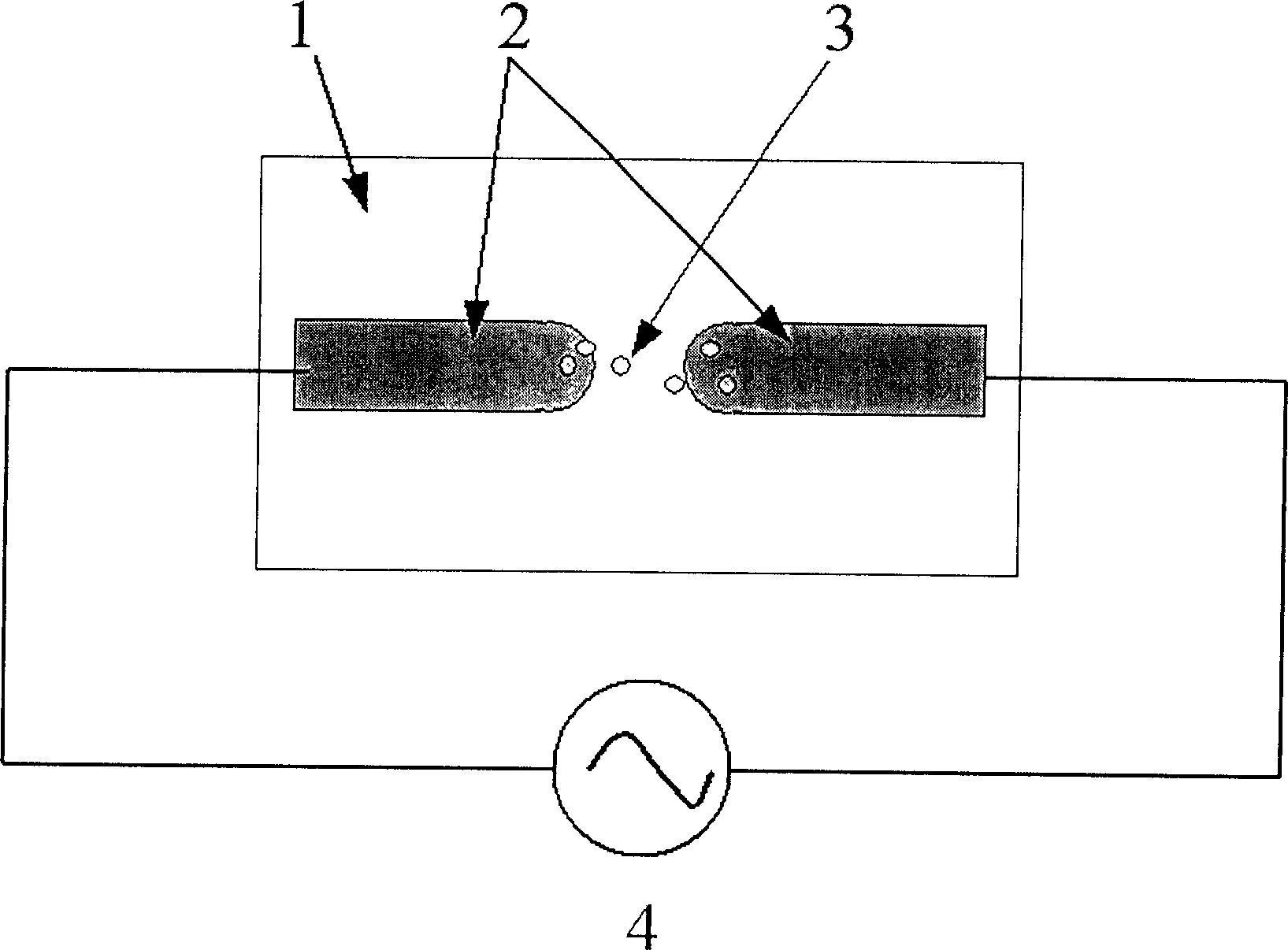

[0023] 1. Coating polymethyl methacrylate / poly(methyl methacrylate-methacrylamide) (PMMA / P(MMA-MAA)) double-layer glue on the silicon dioxide substrate 1 as an electron beam resist etchant; use the electron beam exposure method to etch grooves with a width and depth of about 200 nanometers on the surface of the double-layer glue, the electron beam acceleration voltage used is 20 kV, and the beam spot size is 0.1 micron; The evaporator evaporates gold with a thickness of about 15 nanometers on the surface, thereby depositing gold electrodes in the groove; when evaporating gold, the vacuum degree must be higher than 1.0×10 -3 Pa, control the temperature of the silicon dioxide substrate to be room temperature, and the thickness of the gold film on the evaporation can be controlled by a monitor; then use an ion beam etching machine to make polymethyl methacrylate / poly(methyl methacrylate-methacrylic acid) Dilute amide) double-layer glue is removed, promptly obtains gold electrode ...

Embodiment 2

[0031] 1, coat DNQ phenolic resin glue on the silicon dioxide substrate 1 as electron beam resist; Etch out the groove that width and depth are about 200 nanometers on this glue surface with electron beam exposure method, the adopted electron beam The accelerating voltage is 20 kV, and the beam spot size is 0.1 micron; then, a vacuum ion beam sputtering apparatus is used to grow platinum with a thickness of about 15 nanometers on the surface, thereby depositing a platinum electrode in the groove; the thickness of the platinum film can be monitored by instrument control; then use an ion beam etching machine to remove the DNQ phenolic resin glue to obtain the platinum electrode 2;

[0032] 2. Oxygen flame burns the surface of the platinum electrode prepared above, then puts it into an acetone solution for cleaning, removes organic impurities such as residual photoresist, and obtains a clean platinum electrode 2; the interval between the platinum electrodes is 300 nanometers;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com