Method for preparing composite material capable of forming in situ conductive microfiber network

A technology of composite materials and conductive fillers, which is applied to conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problems of reduced processing performance and mechanical properties, and achieve the effects of low requirements, easy control and low investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

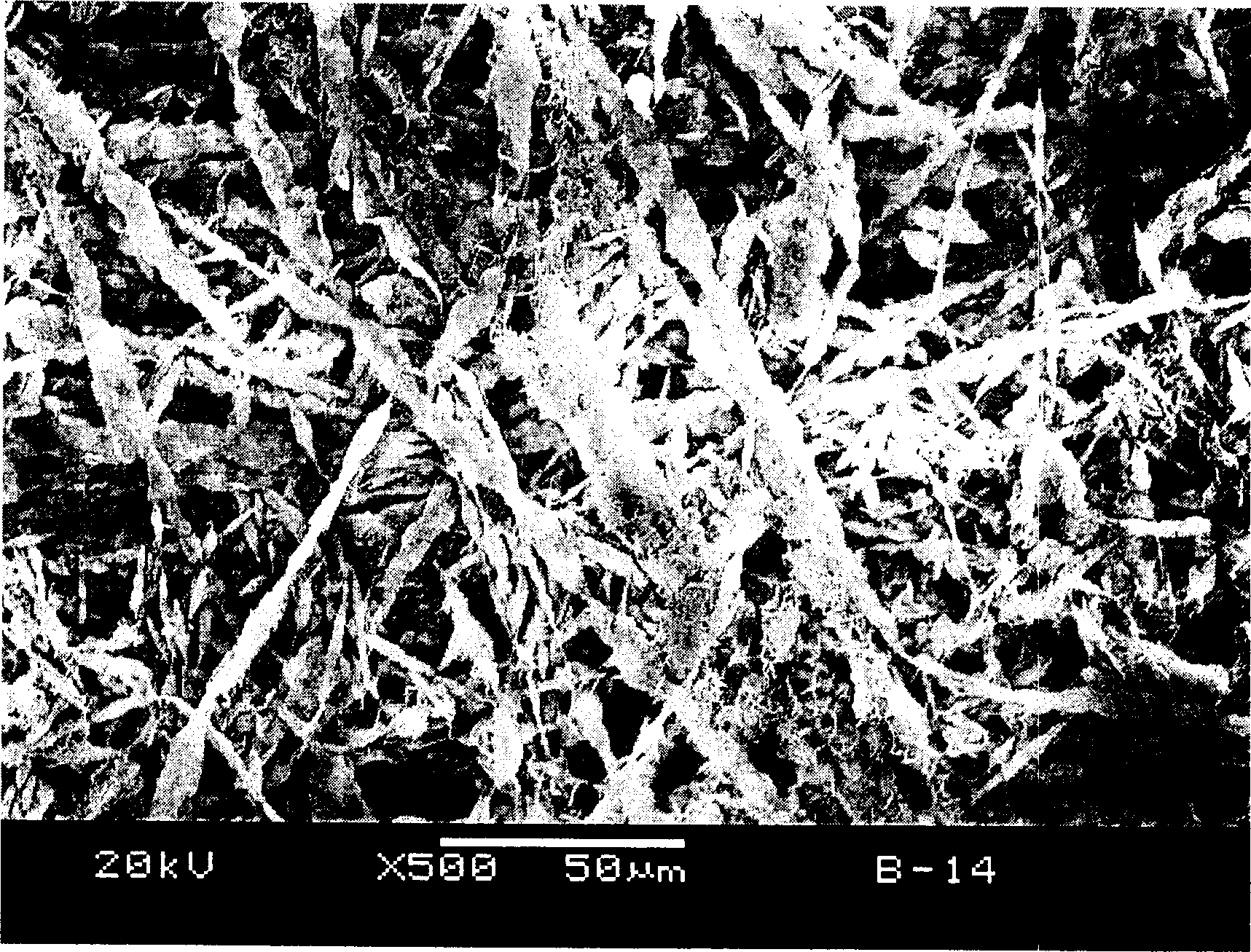

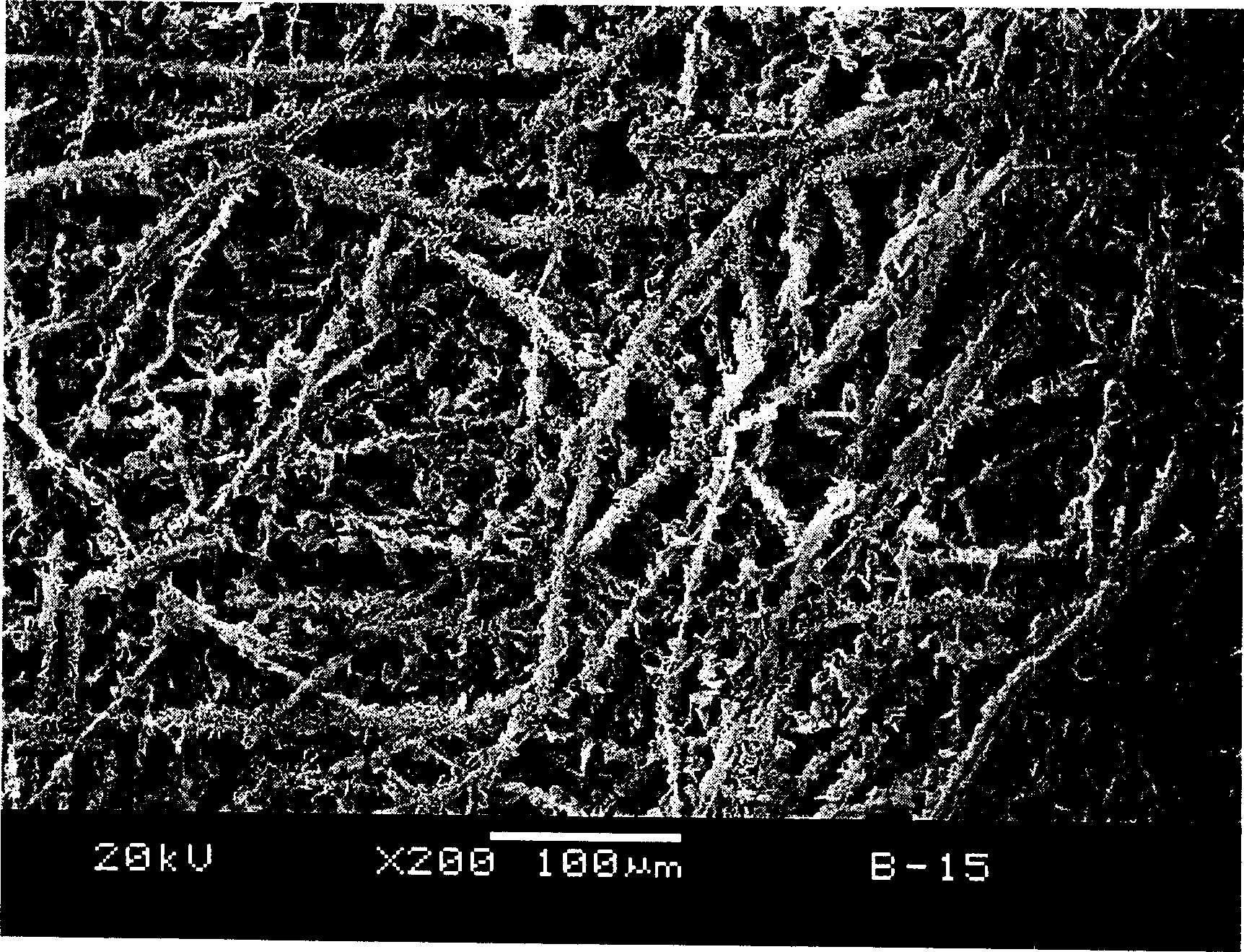

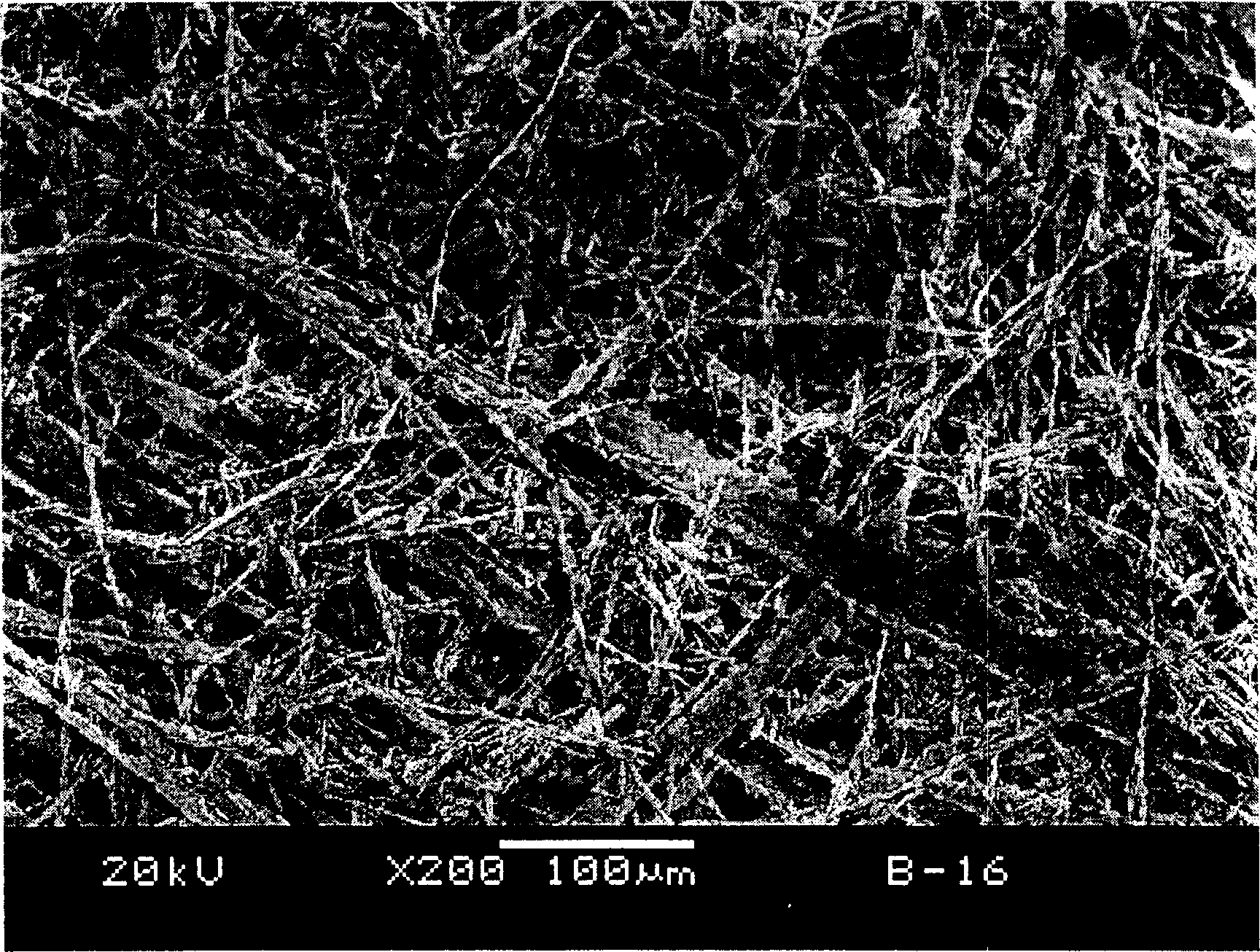

Image

Examples

Embodiment 1~22

[0037] (1) Drying: Dry the low-melting-point thermoplastics, high-melting-point thermoplastics, and conductive fillers at 70-140°C for 8-24 hours according to the proportions given in Table 1, and control the moisture content to <0.01%;

[0038] (2) Melt mixing Put the dried and cooled high-melting point thermoplastic and conductive filler into an open mixer or internal mixer according to the ratio, and melt and mix at a temperature of 200-290°C for 5-25 minutes to prepare a masterbatch;

[0039] (3) Crushing: cooling and crushing the masterbatch obtained by melting and mixing into fine particles with a particle size of 1 to 5 mm;

[0040] (4) Drying Dry the masterbatch obtained after crushing at 70-140°C for 8-16 hours, and control the moisture content to <0.01%;

[0041] (5) Melt mixing extrusion Put the crushed and dried masterbatch and low-melting point thermoplastics in proportion to melt, mix and extrude in an extruder. The extrusion temperature is 175-295°C, and the die...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com