A Modeling Experimental Method for Simulating Engine Mixing

An experimental method and engine technology, applied in the direction of engine testing, machine/structural component testing, instruments, etc., can solve problems such as lack of economical and effective experimental methods, restricting the development of engine configuration optimization design, and difficulty in measuring flow field parameters.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

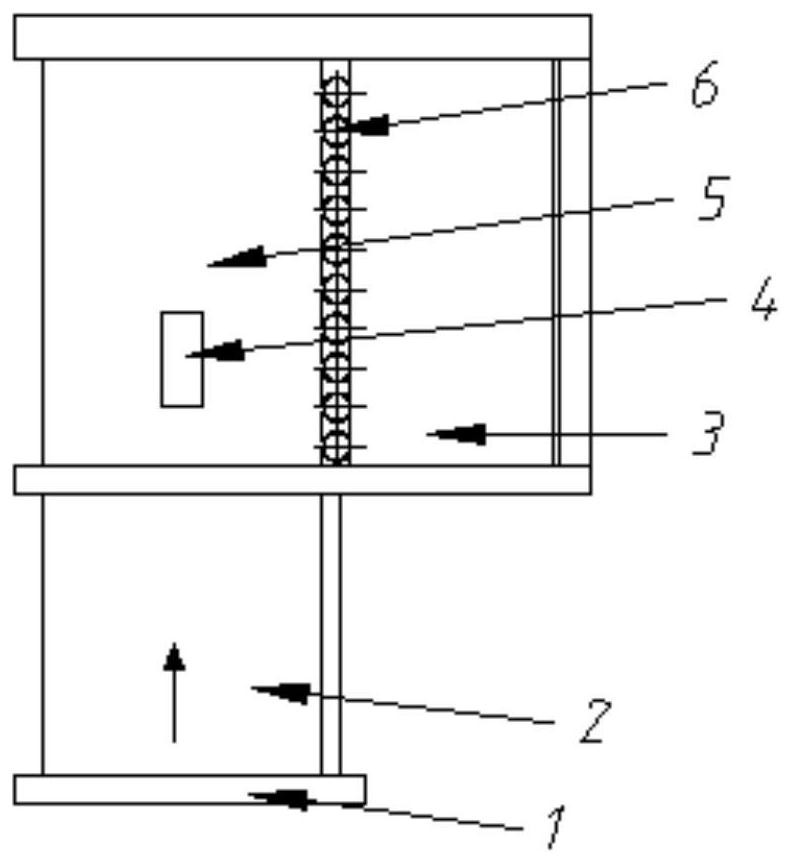

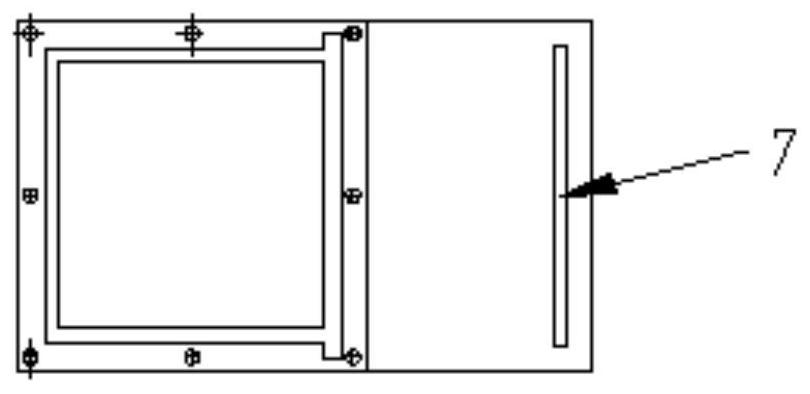

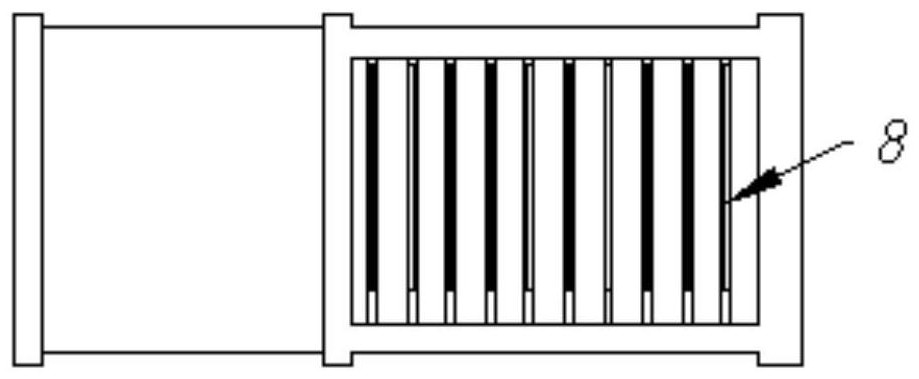

Image

Examples

Embodiment 1

[0043] A thermal power engine uses water and high-temperature gas for mixing. The mixing chamber structure is a rectangular cavity with a cross-sectional size of 95×95mm and a length of 550mm. The pressure of the mixing chamber is 2.5MPa, the gas temperature is 1500K, and the gas mass flow rate is 0.92kg. / s, gas density 5.36kg / m 3 , the water-fuel ratio is 1.0, the atomized particle size D32 of water is 120um, the initial droplet velocity is 22m / s, and the nozzle atomization cone angle is 80°. Using the modeling method proposed in this paper, acetone and heated air are used for mixing in the modeling experiment. The structural size of the mixing chamber is the same as that of the engine mixing chamber (cross-sectional size 95×95mm, length 550mm), and the pressure of the mixing chamber is 0.1 MPa, heating air temperature is 573K, air velocity is 26m / s, acetone atomized droplet D32 is 40μm, initial velocity is 20m / s, acetone mass flow rate is 0.2kg / s, according to acetone atomi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com