Membrane rector with rotary brush

A technology of membrane bioreactor and bioreactor, applied in the direction of sustainable biological treatment, biological water/sewage treatment, membrane, etc., can solve problems such as complex operation, achieve simple process and reduce aeration energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

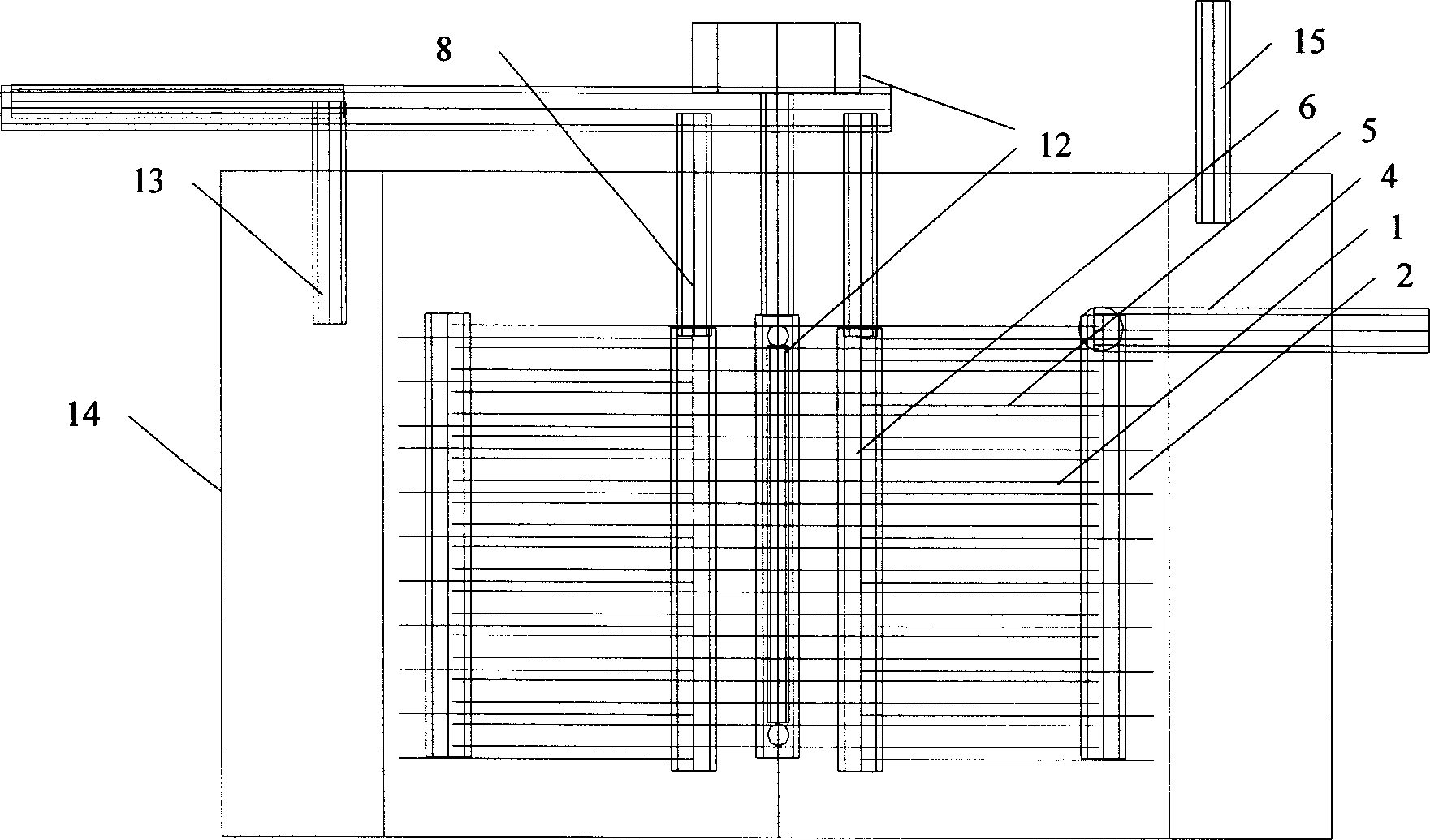

[0031] See attached figure 1 , 2 , 3 and 4. The membrane filament of the hydrophilic membrane module 3 is a hollow fiber microfiltration membrane 1, one end is closed, and the other end is connected to the water collection pipe 2. 4 connected. The membrane filaments of the hydrophobic membrane module 7 are hollow fiber membranes 5 placed in parallel with the hydrophilic membrane module 3 . Rotating brush 12 is made up of adjustable speed motor 9, base frame 10 and hair brush 11, and the rotation of adjustable speed motor drives base frame 10 and hair brush 11 to rotate. The bioreactor 14 is cylindrical, and is connected with an inlet pipe 8 , a water inlet pipe 13 , an outlet pipe 4 and an exhaust pipe 15 , and has a built-in rotating brush 12 . The waste water enters the bioreactor 14 through the water inlet pipe 13, and the hydrophobic membrane module 7 is bubble-free oxygenated so that the oxygen in the reactor 14 is sufficient. The rotation of the rotating brush 12 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com