Method of raising the medium temperature antioxygenation of Ti3AlC2

An anti-oxidation and anti-oxidation technology, applied in the field of anti-oxidation, can solve the problems of application limitations, poor anti-oxidation, etc., achieve good anti-oxidation ability, and combine good effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

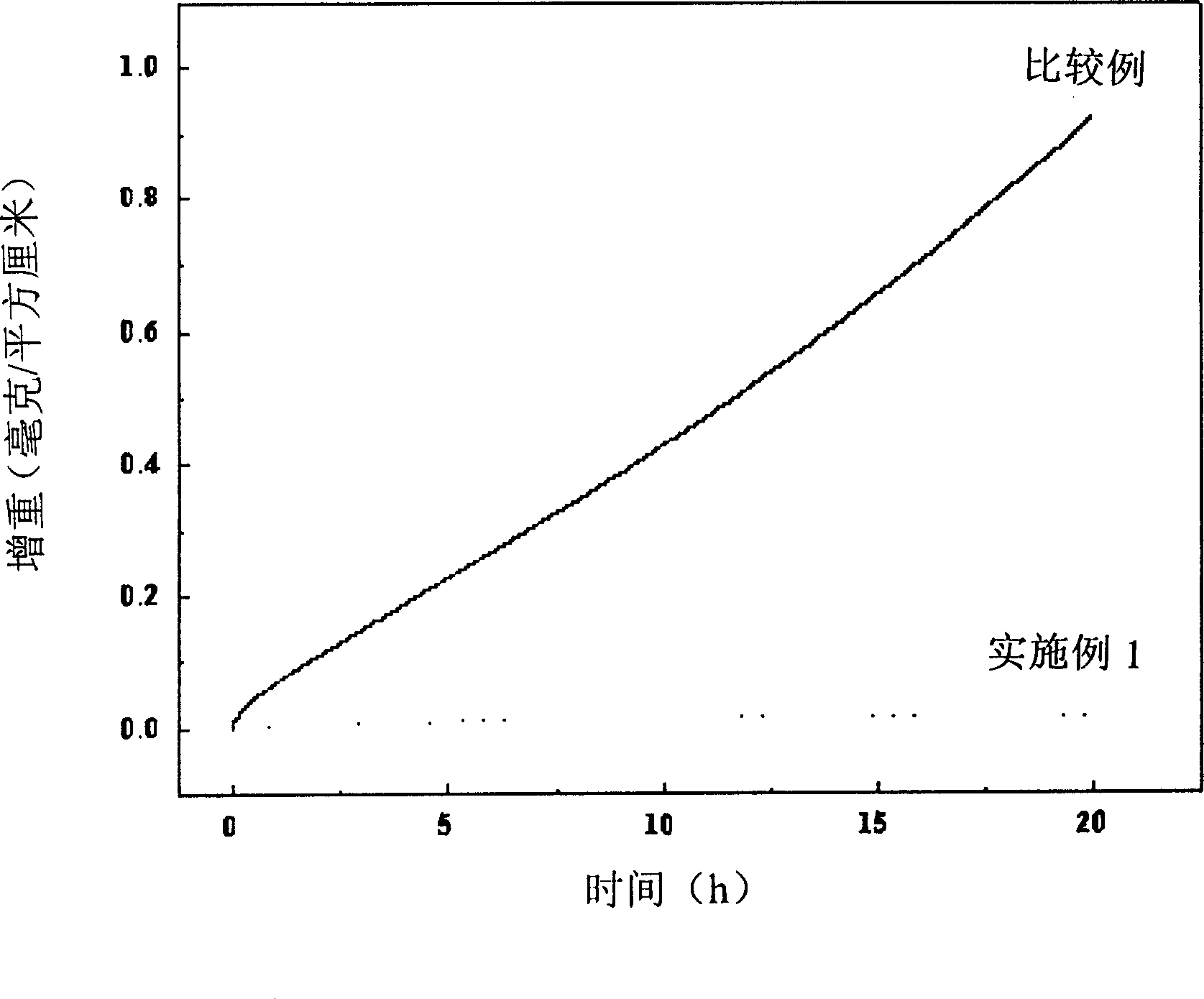

[0014] Ti 3 AlC 2 Expose to still air, the treatment temperature is 1000°C, the pre-oxidation (holding) time is 2 hours, the furnace is cooled, and a protective oxide film is formed after pre-oxidation ( figure 1 ). The pre-oxidation effect is evaluated by the relationship between the oxidation gain and the exposure time measured by the thermobalance. Compared with the sample without oxidation treatment, the sample after pre-oxidation treatment in air at 1000 °C for two hours is oxidized in air at 600 °C for 20 The weight gain per hour decreased significantly, only 1 / 50 of the unoxidized sample, and the oxidation kinetics followed the parabolic law, rather than the linear law of the unoxidized sample (see figure 2 ). This shows that the samples pre-oxidized in air at 1000°C have good long-term oxidation resistance.

[0015] Ti 3 AlC 2 The preparation of the bulk polycrystalline material adopts the method described in the patent application (application number 00123203.7...

Embodiment 2

[0019] Ti 3 AlC 2 Placed in flowing oxygen, the treatment temperature is 1100 ° C, the pre-oxidation (holding) time is 1 hour, furnace cooling, compared with the sample without oxidation treatment, the oxidation of the sample after pre-oxidation treatment in air at 1100 ° C is 20 The hourly weight gain decreased significantly, only 1 / 50 of the unoxidized sample, and the oxidation kinetics of oxidation at 600 ° C for 20 hours followed the parabolic law, not the linear law of the unoxidized sample.

Embodiment 3

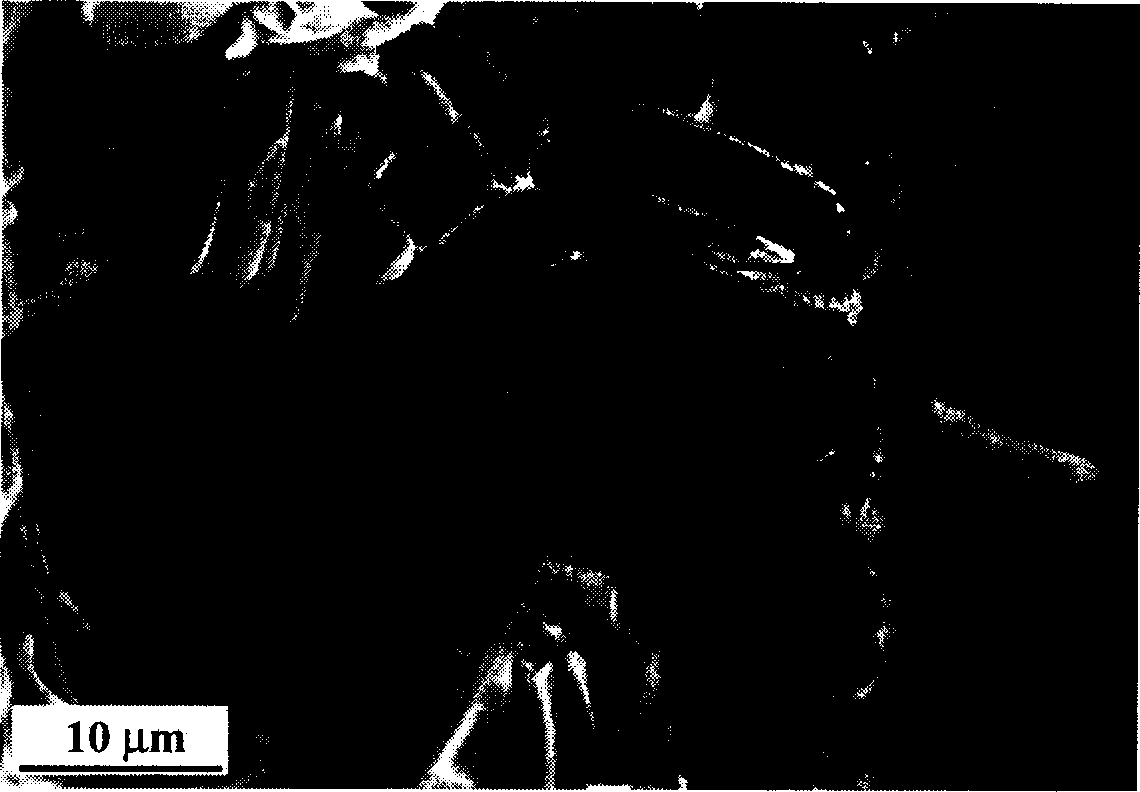

[0021] Ti 3 AlC 2 Expose to flowing dilute oxygen, the partial pressure is 0.1Pa, the treatment temperature is 1200°C, the pre-oxidation (holding) time is 3 hours, the furnace is cooled, the protective oxide film formed after pre-oxidation is further thickened, and at 600°C After 100 hours of oxidation, the weight gain is only 0.12mg / cm 2 . Figure 4 gives the Ti after preoxidation in air at 1200°C for 3 hours 3 AlC 2 Fracture scanning electron micrographs of oxidation at 600°C for 100 hours. It shows that even if it is oxidized for a long time (100 hours), the oxide layer is well combined with the substrate, and no voids and cracks are found between the oxide layer and the substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com