Combined determination method for content of calcium and chlorine in solid sintering aid

A technology of sintering aid and determination method, which is applied in the field of chemical analysis and detection to achieve the effects of improving accuracy and rapidity, avoiding property changes, and improving analysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

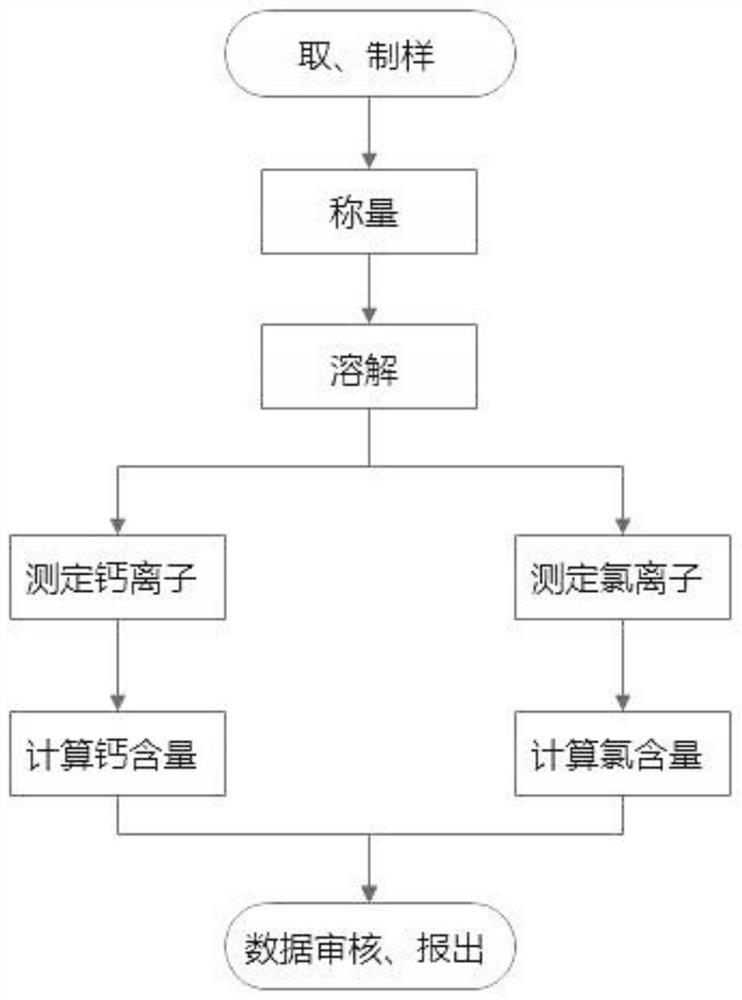

[0068] Embodiment 1: see figure 1 , a joint determination method of calcium and chlorine content in a solid sintering aid, said method comprising the following steps:

[0069] Step 1: Sampling and sample preparation, use a sampler to quickly collect samples of sintering aids, and store them in airtight storage. The samples do not need to be prepared and can be directly used for determination and analysis;

[0070] Step 2: Sample weighing, use an electronic balance to quickly weigh about 1g of sample, no need for accurate weighing, just record the weighing amount directly;

[0071] Step 3: Decompose the sample, heat it with an appropriate amount of distilled water at low temperature to dissolve the sample completely, and set the volume after cooling;

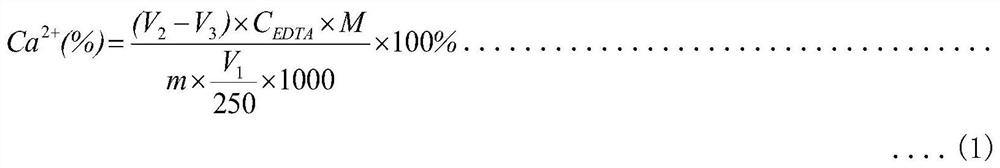

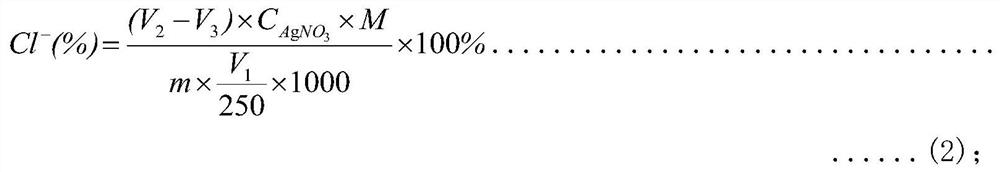

[0072] Step 4: Calcium content detection, take a part of the sample solution, mask the interfering ions, use calcium carboxylic acid (calcium indicator) as the indicator in a strong alkaline medium, and titrate with ethylenediam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com