Preparing method for nano titanium dioxide

A nano-titanium dioxide and titanium raw material technology, applied in titanium dioxide, titanium oxide/hydroxide, chemical/physical/physical-chemical mobile reactors, etc., can solve the problem of slow speed, reduce the volume, strengthen the mass transfer process, The effect of shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

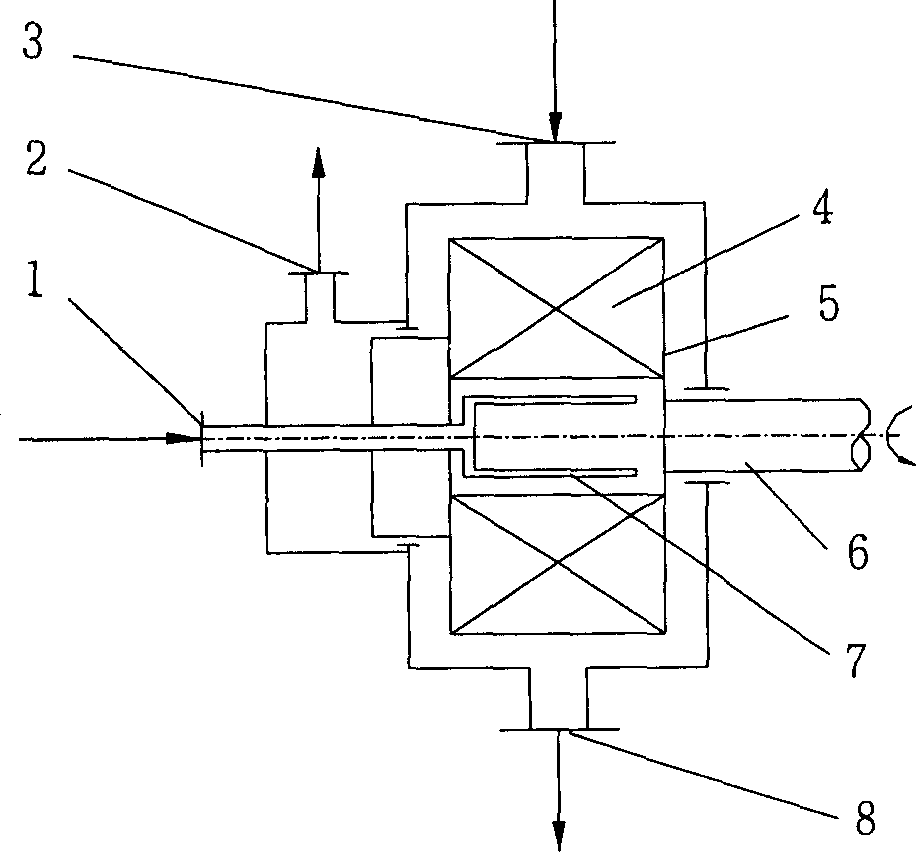

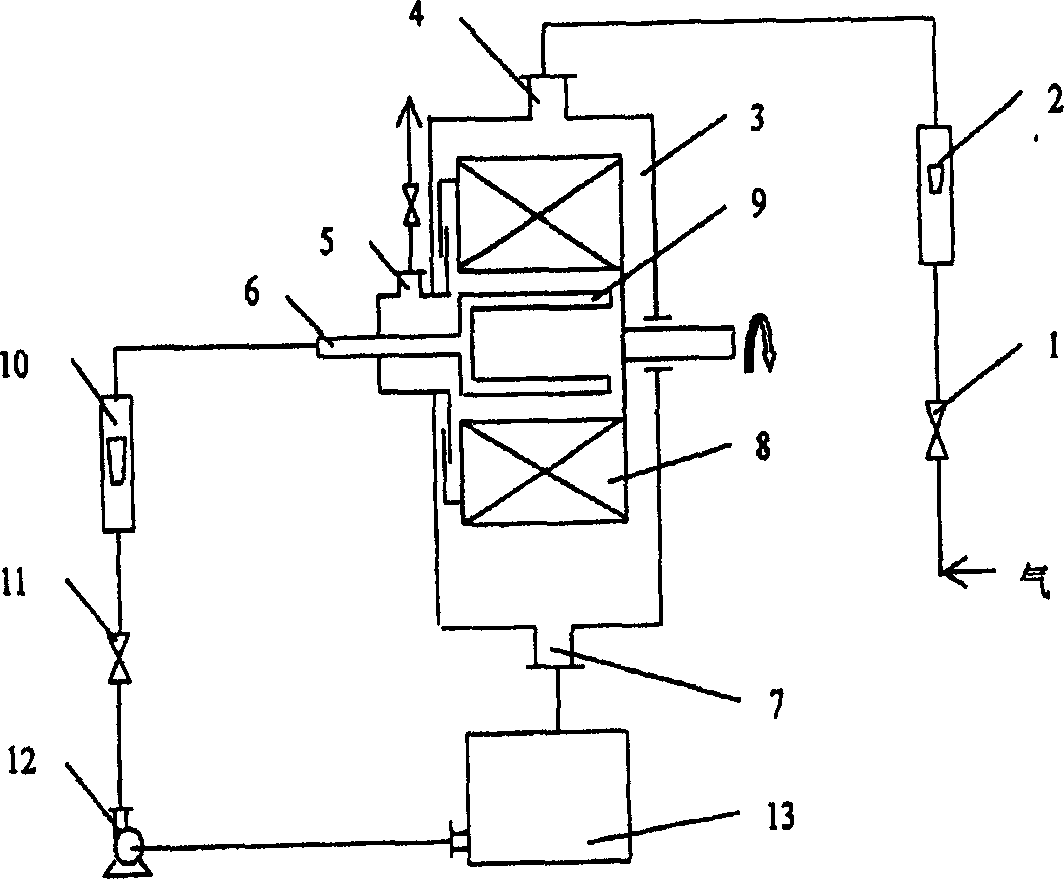

[0041] TiCl 4 As a precursor, ammonia is used as an alkaline gas to prepare nano-titanium dioxide image 3 The process flow shown.

[0042] Prepare TiCl with a concentration of 0.2mol / L 4 Solution, placed in the stirring tank 13. Turn on pump 12 to make TiCl 4 The solution flows through the regulating valve 11, the liquid flow meter 10, and enters the filler 8 through the inlet 6 through the liquid distributor 9, and flows from the inner edge of the rotor to the outer edge to control the TiCl 4 The flow rate of the solution is 200L / h; after the ammonia gas is decompressed from the gas source of the steel cylinder, it passes through the regulating valve 1 and the gas flow meter 2, and continuously enters the rotating bed from the air inlet 4, and flows from the outer edge of the rotor to the inner edge. It is 400L / h. TiCl 4 The solution and ammonia gas are in reverse contact in the filler layer of the rotor, neutralization and hydrolysis reactions occur, and hydrated tita...

Embodiment 2

[0046] Except following change, all the other are the same as embodiment 1.

[0047] The precursor was changed to Ti(SO 4 ) 2 , the concentration is 0.2mol / L, the flow rate is 200L / h, the obtained nano-titanium dioxide is also anatase type, and the particle size is about 20nm, such as Image 6 shown.

Embodiment 3

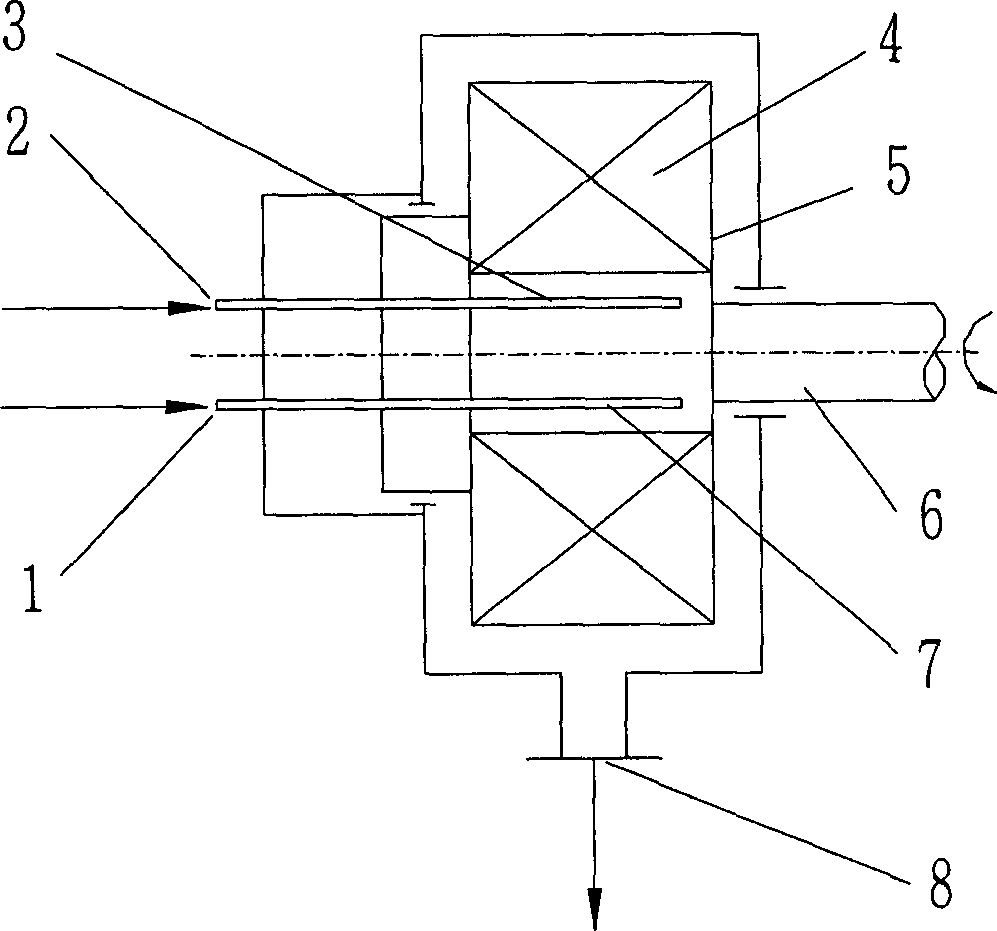

[0049] TiCl 4 As the precursor, ammonia water is used as the lye to prepare nano-titanium dioxide Figure 4 The process flow shown. Prepare TiCl with a concentration of 0.2mol / L 4 The solution is placed in the stirred tank 1, and the ammonia water with a concentration of 2.5% is placed in the stirred tank 8. After turning on pump 3 and pump 7 at the same time, the TiCl 4 The solution and ammonia water flow into the supergravity rotating packed bed reactor at the same time (such as figure 2 shown). TiCl 4 The solution and ammonia mix vigorously in the filler and react to form hydrated titanium dioxide. The reaction product leaves the high-gravity rotating bed reactor through the liquid outlet 5 after being thrown out from the filler. During the reaction TiCl 4 The flow rates of the solution and ammonia water were both 200 L / h, the rotational speed of the rotary bed rotor was 1200 r / min, and the reaction was carried out at room temperature.

[0050] The hydrated titani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com