Natural gas re-burning nozzle for coal boiler

A technology for coal-fired boilers and natural gas, applied in gas fuel burners, burners, incinerators, etc., can solve the problems of affecting the effect of reducing nitrogen oxides, not fully considering the mixing and diffusion characteristics of natural gas, etc., and achieve the scope of reducing atmosphere. Wide and evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

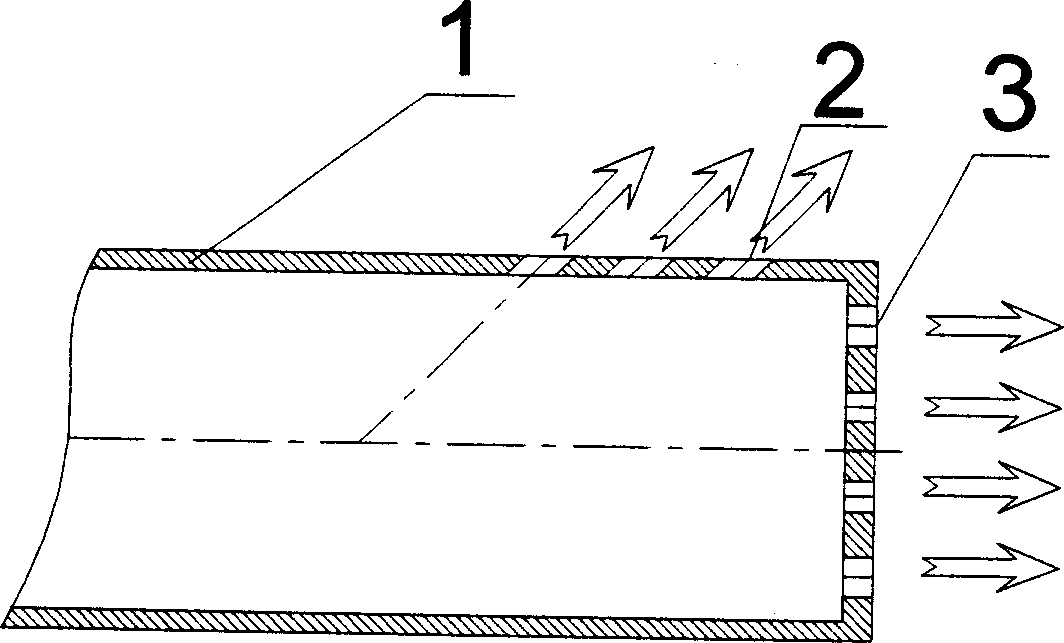

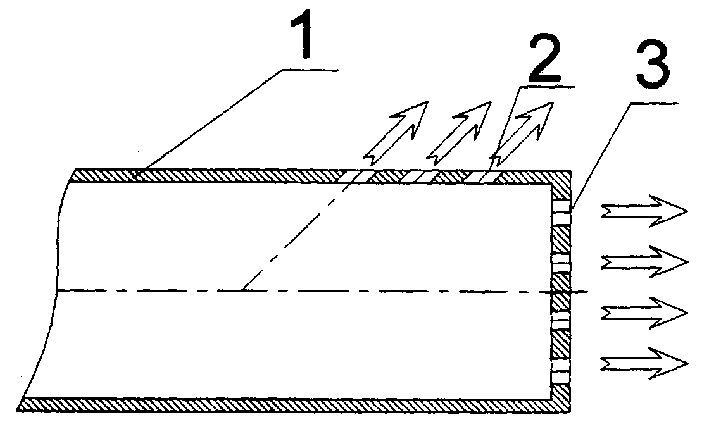

[0014] figure 1 It is a front sectional view of the structure of the natural gas reburning nozzle of the present invention.

[0015] Such as figure 1 As shown, on the semicircle of the nozzle 1, there are many oblique injection holes 2 evenly arranged in layers, and the angle between the axis of each oblique injection hole 2 and the axis of the nozzle is 15° to 75°. A number of axial injection holes 3 are evenly opened on the end cap at the end of 1, and the axes of the axial injection holes 3 are parallel to the axial direction of the nozzle.

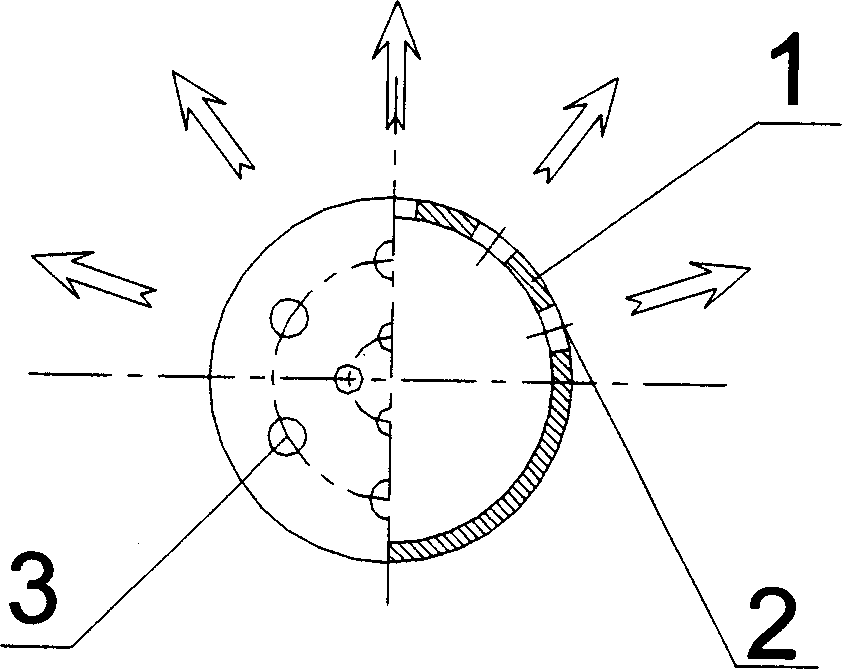

[0016] figure 2 It is a side view half-sectional view of the structure of the natural gas reburning nozzle of the present invention.

[0017] Such as figure 2 As shown, a number of axial injection holes 3 are evenly opened on the end cover of the nozzle 1, and the axes thereof are parallel to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com