Biomass fuel and semi-coke mixed burning system and method

A biomass fuel and biomass technology, applied in the direction of combustion methods, solid fuel combustion, fuel supply, etc., can solve problems such as difficulties, and achieve the effects of enhancing adaptability, reducing energy consumption, and reducing NOx emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

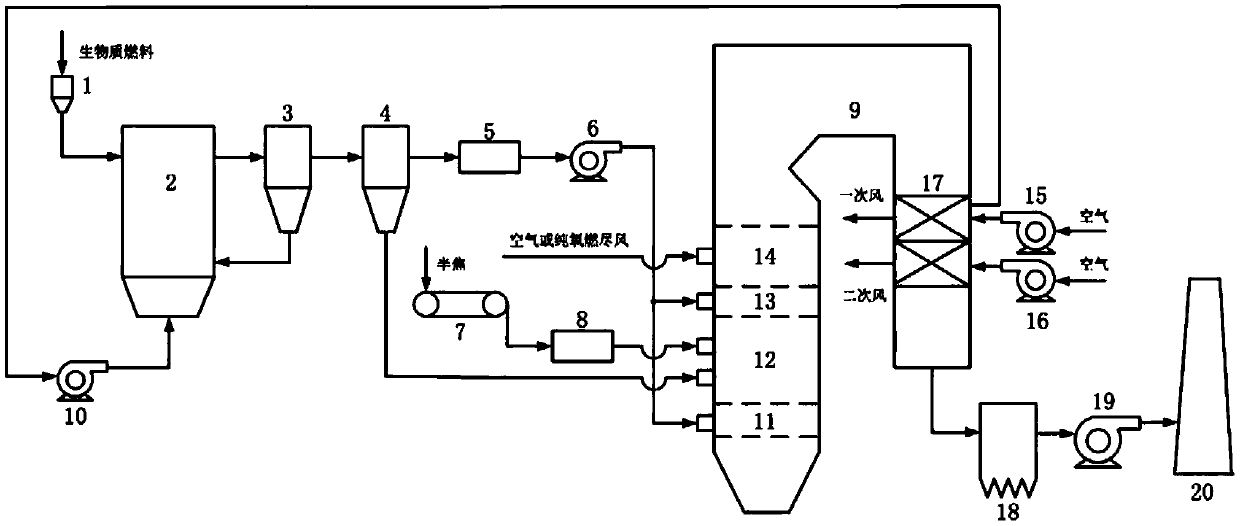

[0028] The present invention is described in further detail below in conjunction with accompanying drawing:

[0029] see figure 1 , a system for co-combustion of biomass fuel and semi-coke provided by the present invention, comprising a feeder 1, a biomass gasifier 2, a primary cyclone separator 3 and a secondary cyclone separator 4, a cyclone dust collector 5, High-temperature fan 6, coal feeder 7, coal mill 8, boiler body 9, air preheater 17, high-temperature dust collector 18, induced draft fan 19, chimney 20, and the fire zone 11 arranged in the furnace from bottom to top, Primary combustion zone 12, reburning zone 13 and burnout zone 14.

[0030] During operation, the semi-coke enters the main combustion zone 12 of the furnace through the coal feeder 7 and the coal mill 8, and the biomass fuel passes through the feeder 1, the biomass gasifier 2, the primary cyclone separator 3 and the secondary cyclone separator After 4, the gas-solid two phases are separated, and the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com