Preparation method of laminated slice type PTC heat sensitive resistor

A thermistor and lamination technology, applied in the direction of resistors with positive temperature coefficient, etc., can solve the problem that it is difficult to make good contact between the electrode and the ceramic sheet, the thickness of the chip PTC element should not be too thin, and the flatness of the ceramic sheet is difficult. Guarantee and other issues, to avoid the flatness of the tile, the uniformity of the BaTiO3 semiconducting ceramic water slurry, the uniformity of the PTC ceramic body and the sintered body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 (1) superfine BaTiO 3 Preparation of PTC-based powder

[0025] The composition of the PTC sample material is: (Ba 0.8 Sr 0.2 ) Ti 1.02 o 3 +0.6mol%Y 3+ +1mol%Al 3+ +1.5mol%Si 4+ +0.1mol%Mn 2+ . According to the ratio of metal ions in the formula, weigh BaCO 3 , SrCO 3 , Y 2 o 3 , Ti(C 4 h 9 O) 4 , and react with citric acid respectively to obtain the citrate aqueous solution of these four metal ions. The obtained solutions were mixed and ammonia water was added dropwise to adjust the pH value to 7. After uniform stirring by magnetic force, a transparent solution containing four components was obtained. According to the ratio of solution: organic monomer: cross-linking agent = 100ml: 20g: 8g, add acrylamide and N, N'-methylenebisacrylamide, in ammonium persulfate and N, N, N, 'N'- Under the initiation and catalysis of tetramethylethylenediamine, the monomers are cross-linked and polymerized to obtain a white translucent wet gel. After the w...

Embodiment 2

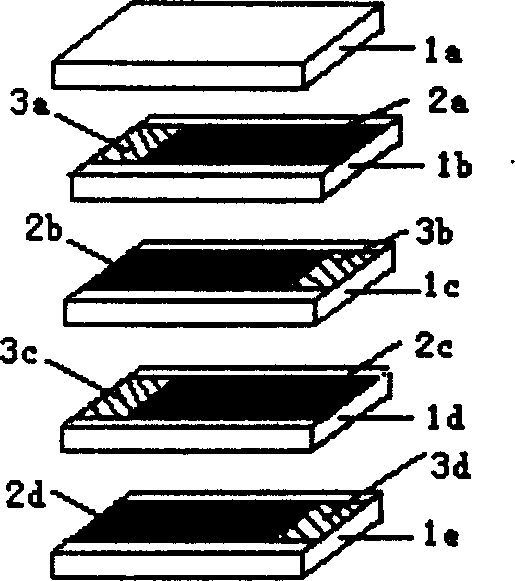

[0032] Use the same steps as in Example 1 to make a laminated chip PTC thermistor. The corresponding parameters are respectively as follows: get the BaTiO obtained in Example 1 3Base PTC powder 40g, add 6ml of water, 1.5ml of polymethacrylic acid solution with a concentration of 10wt%, and 1.5g of acrylamide and 0.04g of N,N'-methylenebisacrylamide, and ball mill for 6 hours to prepare The solid phase content is about 45vol% BaTiO 3 Water based semiconducting porcelain paste. Under the action of ammonium persulfate and N,N,N',N'-tetramethylethylenediamine, the slurry completes the polymerization reaction to form a gel. After 0.5h of solidification and molding, it is fired at 1330°C for 50min to obtain a rod-shaped PTC. For ceramics, the rod-shaped PTC ceramics are cut into chip components with a thickness of 0.4mm. After lamination and electrode firing, a laminated chip PTC thermistor is obtained.

[0033] The multilayer chip PTC thermistor has 5 layers, the size is 11mm×6...

Embodiment 3

[0035] Use the same steps as in Example 1 to make a laminated chip PTC thermistor. The corresponding parameters are respectively as follows: get the BaTiO obtained in Example 1 3 Base PTC powder 40g, add 5.5ml of water, 2ml of polymethacrylic acid solution with a concentration of 10wt%, and 1.5g of acrylamide and 0.01g of N,N'-methylenebisacrylamide, and mix by ball milling for 8 hours to prepare The solid phase content is about 45vol% BaTiO 3 Water based semiconducting porcelain paste. Under the action of hydrogen peroxide and N, N, N', N'-tetramethylethylenediamine, the slurry completes the polymerization reaction to form a gel, which is solidified and formed after 15 minutes, and fired at 1350 ° C for 20 minutes to obtain rod-shaped PTC ceramics , Cut the rod-shaped PTC ceramics into chip components with a thickness of 0.5mm. After lamination and electrode firing, a laminated chip PTC thermistor is obtained.

[0036] The multilayer chip PTC thermistor has 5 layers, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Temperature coefficient of resistance | aaaaa | aaaaa |

| Temperature coefficient of resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com