Method for preparing titania dioxide gel film electrochemical biological sensor

A biosensor, titanium dioxide technology, applied in biochemical equipment and methods, microbial measurement/inspection, scientific instruments, etc., can solve problems such as fixation, and achieve the effects of simplifying the preparation process, avoiding inactivation, and controllable film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1. Self-assembly to form a titanium dioxide film and preparation of a hydrogen peroxide biosensor

[0025] 1. Cut the ITO electrode into 0.5×1.0cm size, then put it in the detergent and ultrasonically clean it twice for 15 minutes, then ultrasonically clean it in absolute ethanol for 10 minutes, and finally ultrasonically clean it in water for 15 minutes. End After that, dry the electrode and let it stand for use.

[0026] 1.1. Soak the ITO electrode in a 5mol / L sodium hydroxide solution for 10 hours, take it out, and rinse it thoroughly with secondary water and dry it with nitrogen;

[0027] 1.2. Immerse the electrode in 100mM butyl titanate solution for 3 minutes, the solvent is a mixture of ethanol and toluene with a volume ratio of 1:1; then put the electrode in absolute ethanol for one minute, and finally soak the electrode in secondary water One minute.

[0028] 2. Immerse the above modified electrode in a 2mg / mL horseradish peroxidase aqueous solution for 30 ...

Embodiment 2

[0031] Example 2. Self-assembly to form a titanium dioxide film and preparation of a hydrogen peroxide biosensor

[0032] 1. Cut the ITO electrode into 0.5×1.0cm size, then put it in the detergent and ultrasonically clean it twice for 15 minutes, then ultrasonically clean it in absolute ethanol for 10 minutes, and finally ultrasonically clean it in water for 15 minutes. End After that, dry the electrode and let it stand for use.

[0033] 1.1. Soak the ITO electrode in a 2mol / L sodium hydroxide solution for 12 hours, take it out and rinse it thoroughly with secondary water, and dry it with nitrogen;

[0034] 1.2. Immerse the electrode in a 200mM butyl titanate solution for 2 minutes, the solvent is a mixture of ethanol and toluene with a volume ratio of 3:1;

[0035] 1.3. Soak the electrode in absolute ethanol for 3 minutes;

[0036] 1.4. Soak the electrode in the secondary water for 3 minutes;

[0037] 2. The modified electrode is immersed in a 2mg / mL horseradish peroxidase aqueous ...

Embodiment 3

[0039] Example 3. Self-assembly to form a titanium dioxide film and preparation of a hydrogen peroxide biosensor

[0040] The cleaning and surface -OH process of the electrode are the same as in Example 1. After -OH, the electrode can be immersed in a 10% silane coupling agent KH550 aqueous solution for 25 minutes to make the electrode surface -NH 2 The remaining steps are the same as in Example 1.

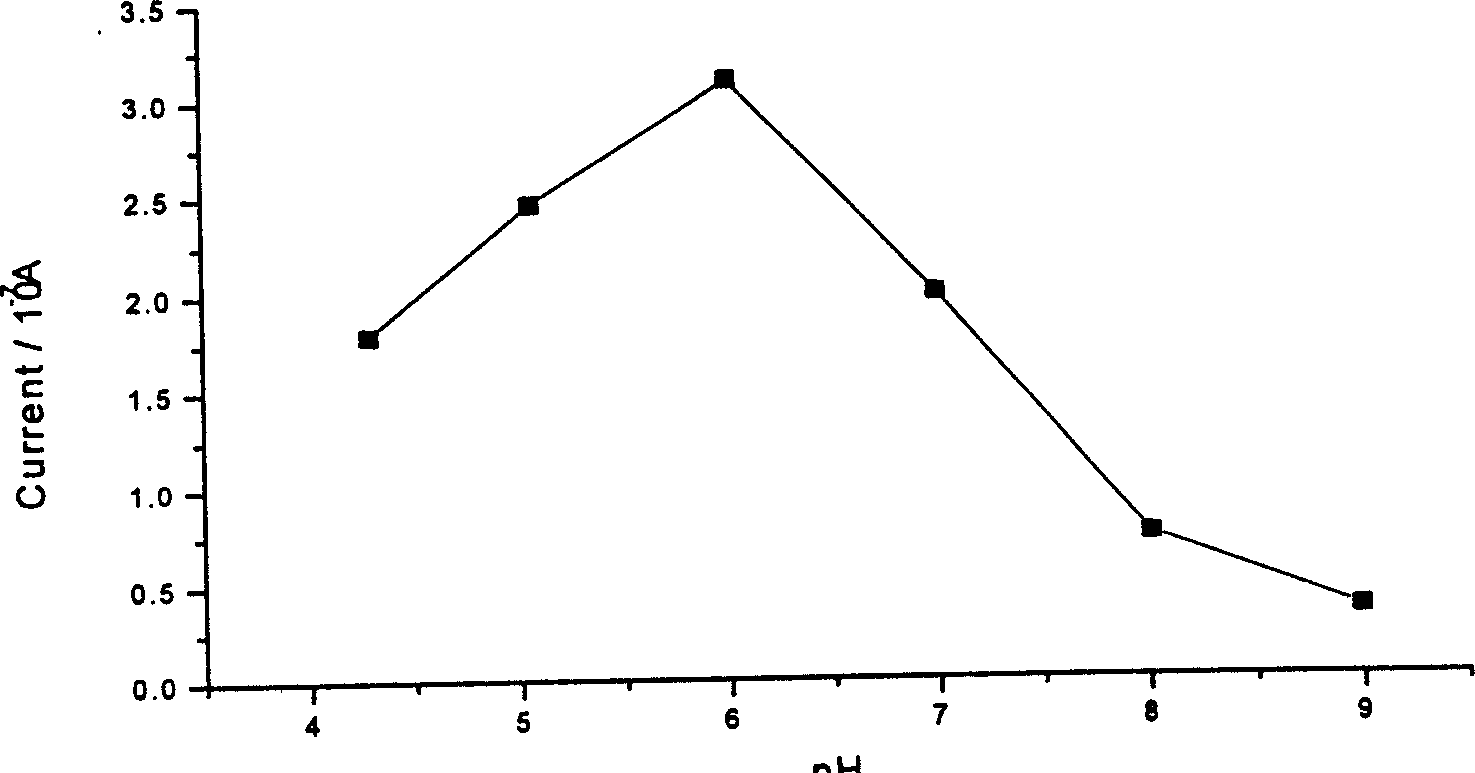

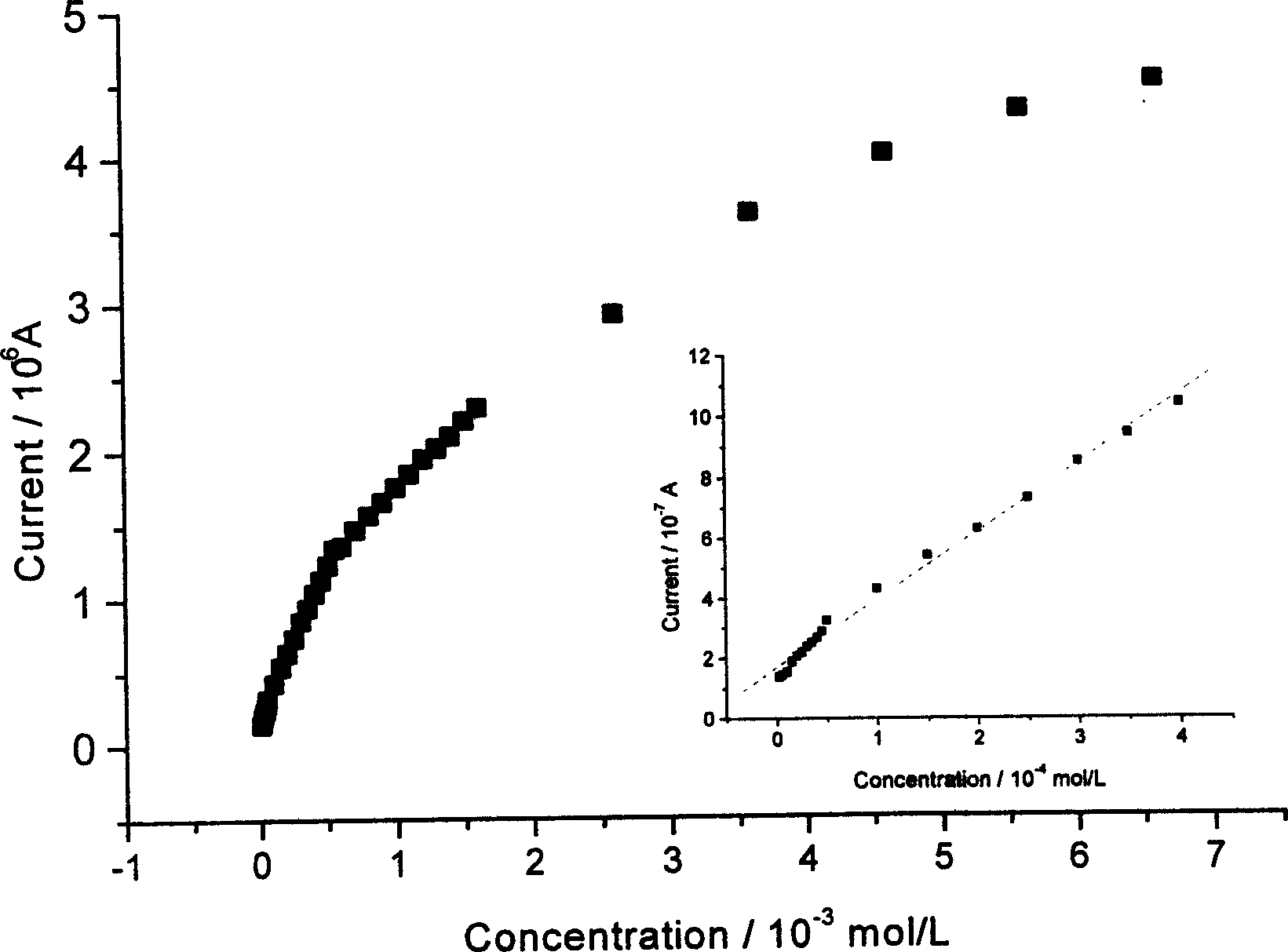

[0041] The obtained biosensor has better performance stability and is stored for one month without deactivation. The choice of experimental conditions is the same

[0042] Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com