Multi-quantum well waveguide butt coupling method

A multi-quantum well and docking coupling technology, which is applied in the coupling of optical waveguides, phonon exciters, semiconductor lasers, etc., can solve the problems of reduced coupling efficiency of multi-quantum well waveguides, affecting the performance of integrated devices, and difficult to guarantee material quality. Achieve the effects of improving stacking bending phenomenon, having universal applicability, and reducing light loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

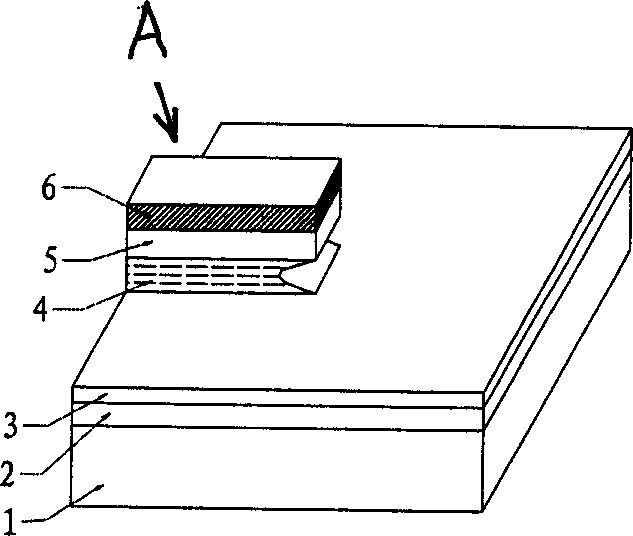

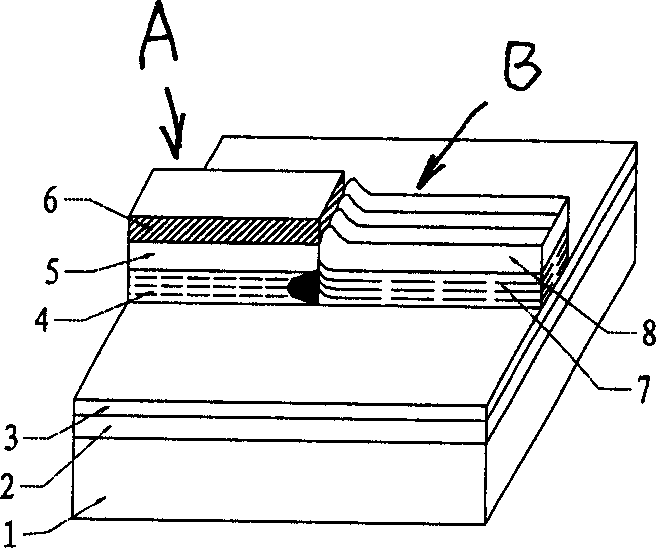

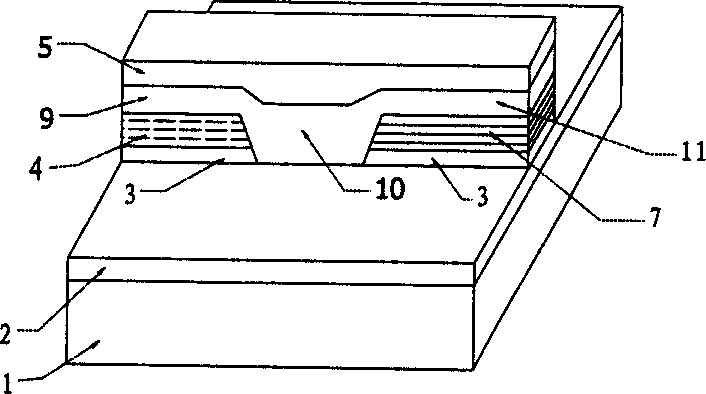

[0037] Figure 4 It is a schematic diagram of the EML structure made by the waveguide butt coupling method. The specific production process is as follows:

[0038] 1. On the (100) surface of n-type indium phosphide (InP) substrate 1, the optimally designed laser multi-quantum well active structure is epitaxially grown, specifically including the lower waveguide layer 2, the InP etch stop layer 3 (with a thickness of 10 -50nm), multiple quantum well (MQW) 4, upper waveguide 5 and InP capping layer 6;

[0039] 2. Deposit a layer of silicon dioxide (SiO2) with a thickness of about 100 nm by thermal oxidation CVD 2 ) Dielectric film, the mask photolithography out the laser table bar (see figure 1 ), the strip width is 10-50um, the strip length is 200-800um, the etching stops at the InP barrier layer 3, and the laser bar end side drills deeper;

[0040] 3. Epitaxial growth modulator active structure (MD-MQW), because silicon dioxide (SiO 2 ) Dielectric film cannot grow crystal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com