Biosensor for lactic acid in whole blood

A biosensor, blood lactic acid technology, applied in the field of biosensors, can solve the problems of interference of changes in oxygen content, poor anti-interference ability, poor redox characteristics, etc., to improve enzyme activity, improve response sensitivity, avoid blood The effect of a change in quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

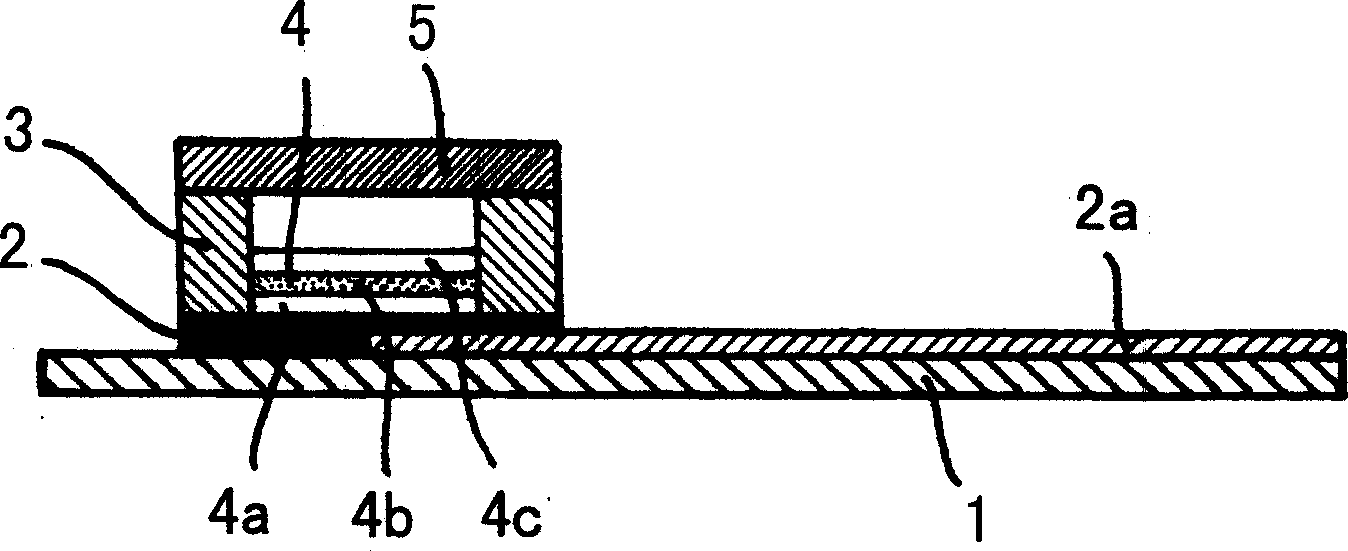

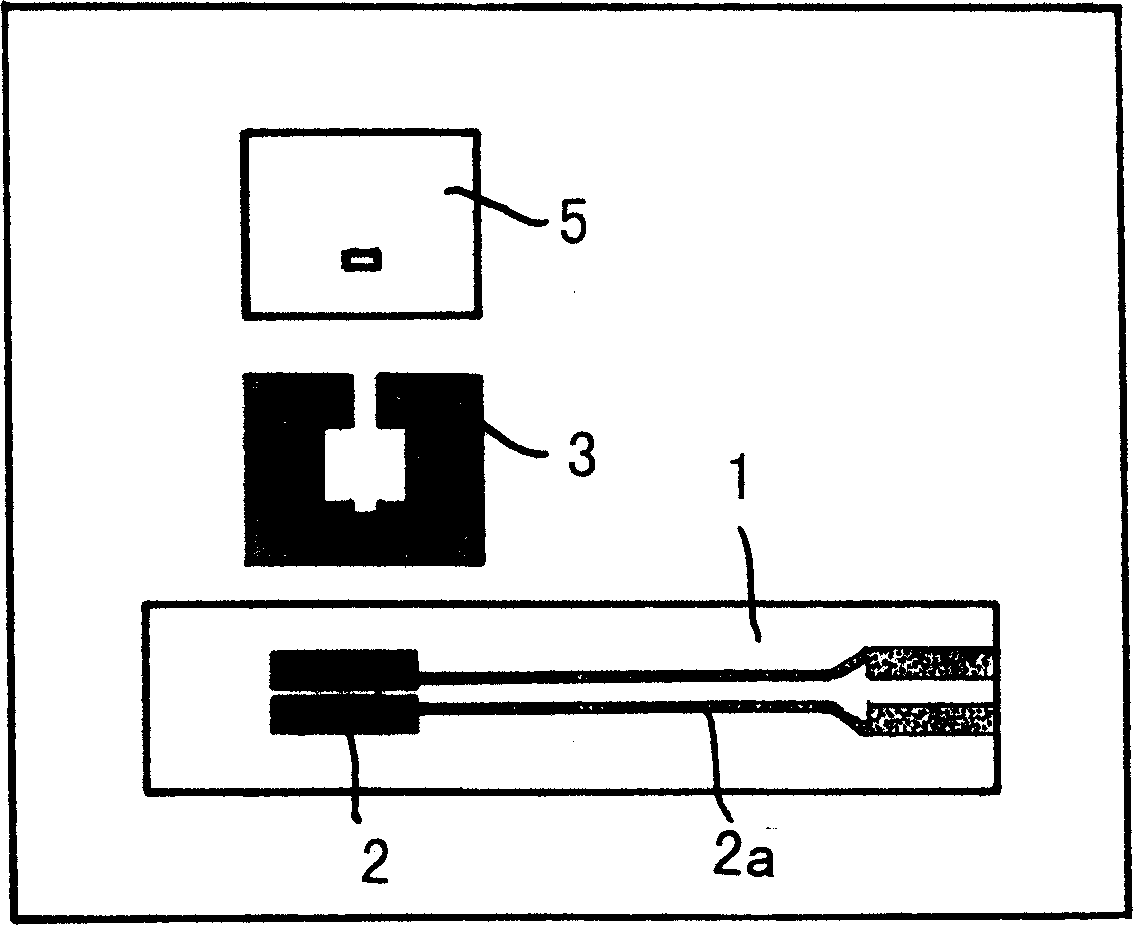

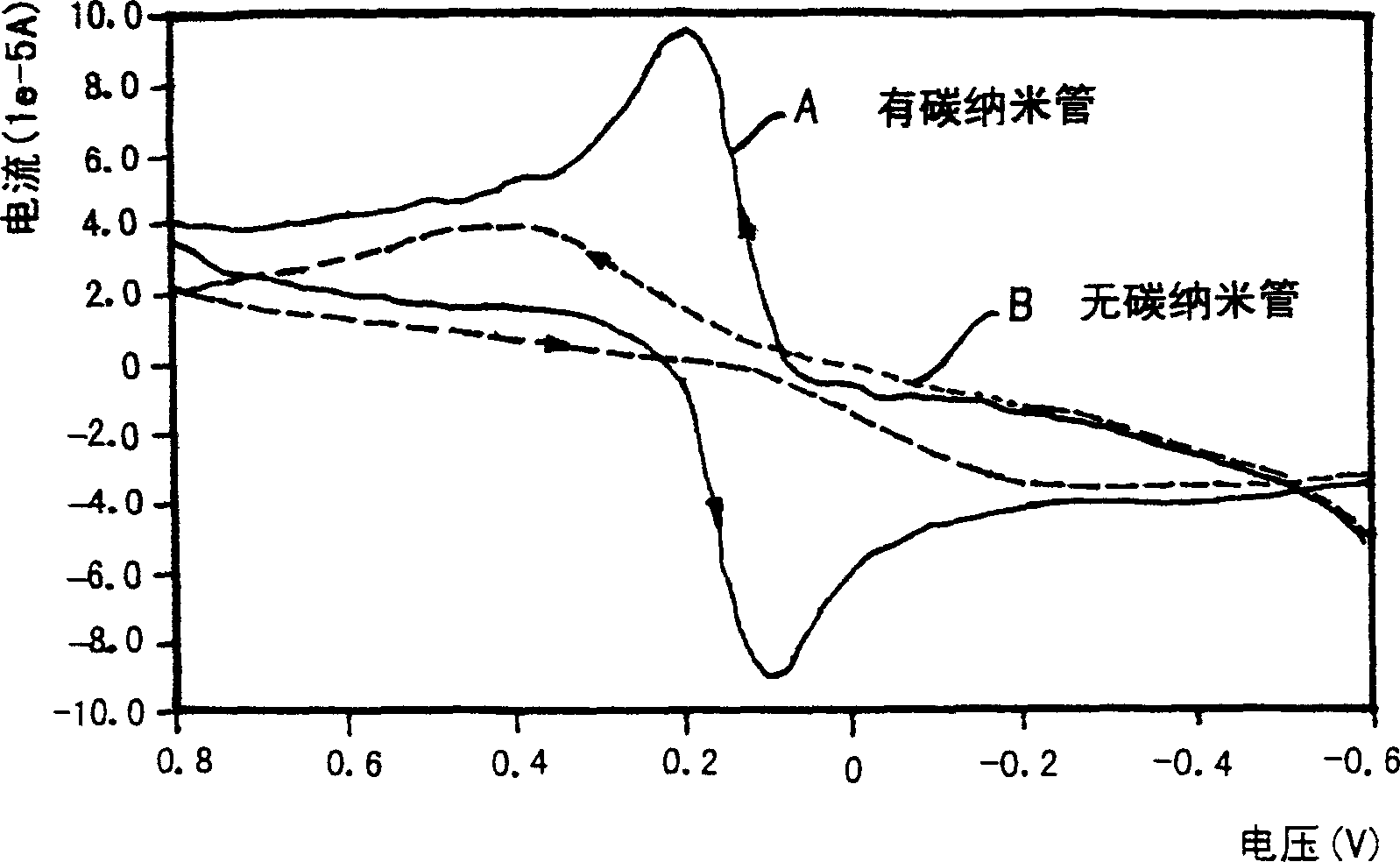

[0011] A whole blood lactate biosensor such as figure 1 As shown, thick-film carbon electrodes 2 and silver electrode leads 2a were made on the PVC base plate 1 by screen printing technology, plastic film was covered around the carbon electrodes 2 to form a cavity 3, and 2μl concentration of 5mg / kg was injected into the cavity. ml CMC solution, the solution is dried in a 60°C oven to form a CMC layer 4a; add 2 μl of modified carbon nanotube suspension with a concentration of 2mg / ml, and after drying in a 60°C oven, a carbon nanotube layer 4b is formed. Then add 2 μl of mixed solution, the composition of which is 500 activity units / ml of L-lactate oxidase, 50 mg / ml of potassium ferricyanide, 20 mg / ml of seaweed, pH value of 6.0, and concentration of 0.2M phosphate buffer solution. The mixed layer 4c formed after drying in the drying oven is then covered with a plastic film on the cavity 2 to determine the volume of the cavity 3, which is 2 μl. The plastic film here is the cavit...

Embodiment 2

[0013] A whole blood lactate biosensor such as figure 1 As shown, thick-film carbon electrodes 2 and silver electrode leads 2a were made on PVC base plate 1 by screen printing technology, plastic film was covered around carbon electrodes 2 to form cavity 3, and 2μl concentration of 20mg / kg was injected into the cavity. ml of carboxymethyl cellulose CMC solution, the solution was oven-dried at 60°C to form a CMC layer 4a; add 2 μl of modified carbon nanotube suspension at a concentration of 6 mg / ml, and after oven-drying at 60°C, a carbon nanotube layer 4a was formed. Nanotube layer 4b, and then add 2μl of mixed solution, the ingredients are L-lactic acid oxidase 1000 activity units / ml, potassium ferricyanide 50mg / ml, bovine serum albumin 40mg / ml, pH value 7.0, the concentration is 0.4M phosphate buffer solution is dried in a drying oven to form a mixed layer 4c, and then a layer of plastic film is covered on the cavity 3 as the cavity cover 5, the volume of the cavity 3 is 2 μ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com