Substance for forming electrically-conducting film and electrically-conducting film and its manufacturing method

A conductive film and composition technology, which is applied in the formation of conductive patterns, electrode system manufacturing, printed circuit manufacturing, etc., can solve the problems that it is difficult to obtain low-resistance aluminum patterns, and it is difficult to manufacture fine patterns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

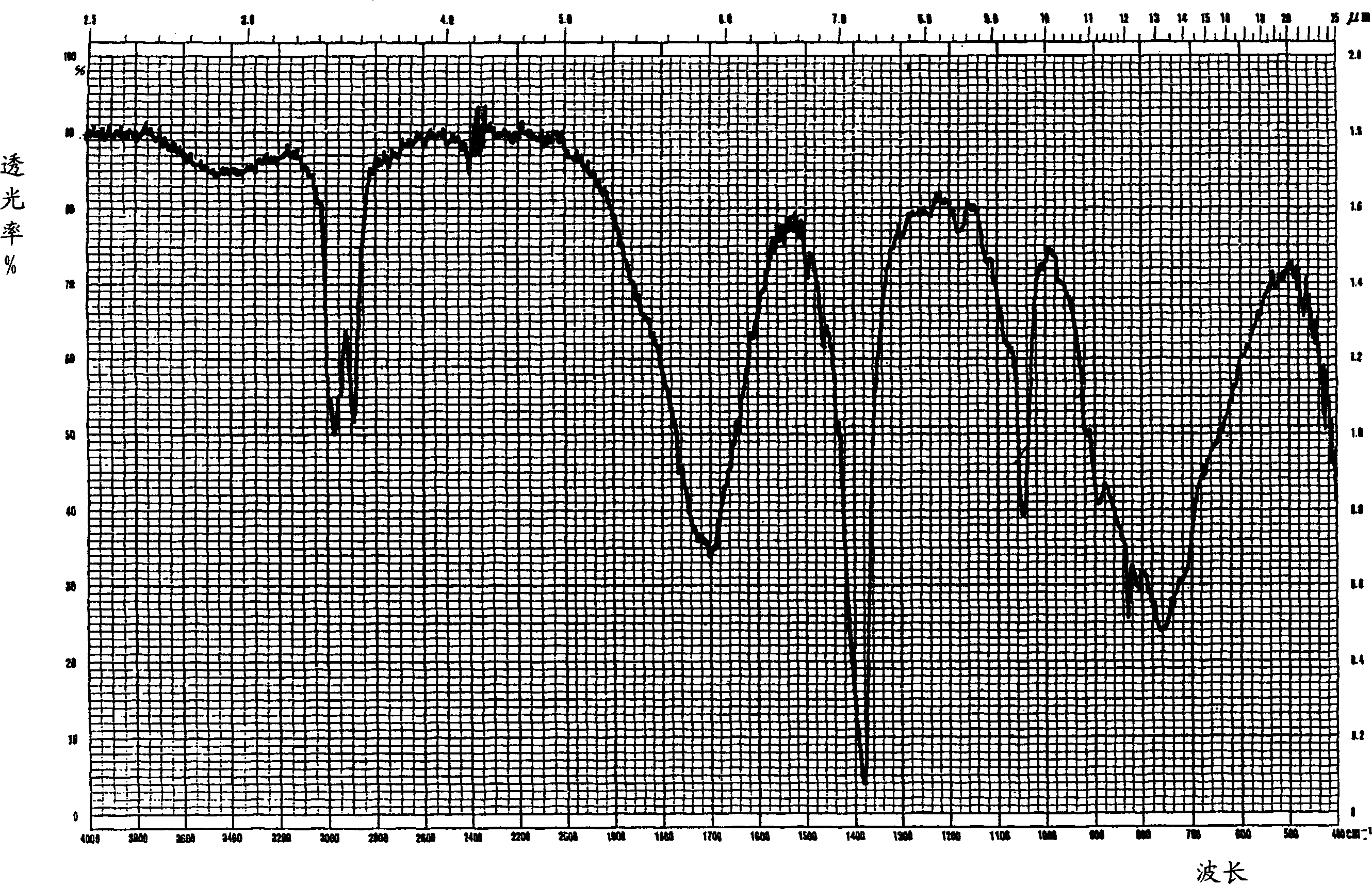

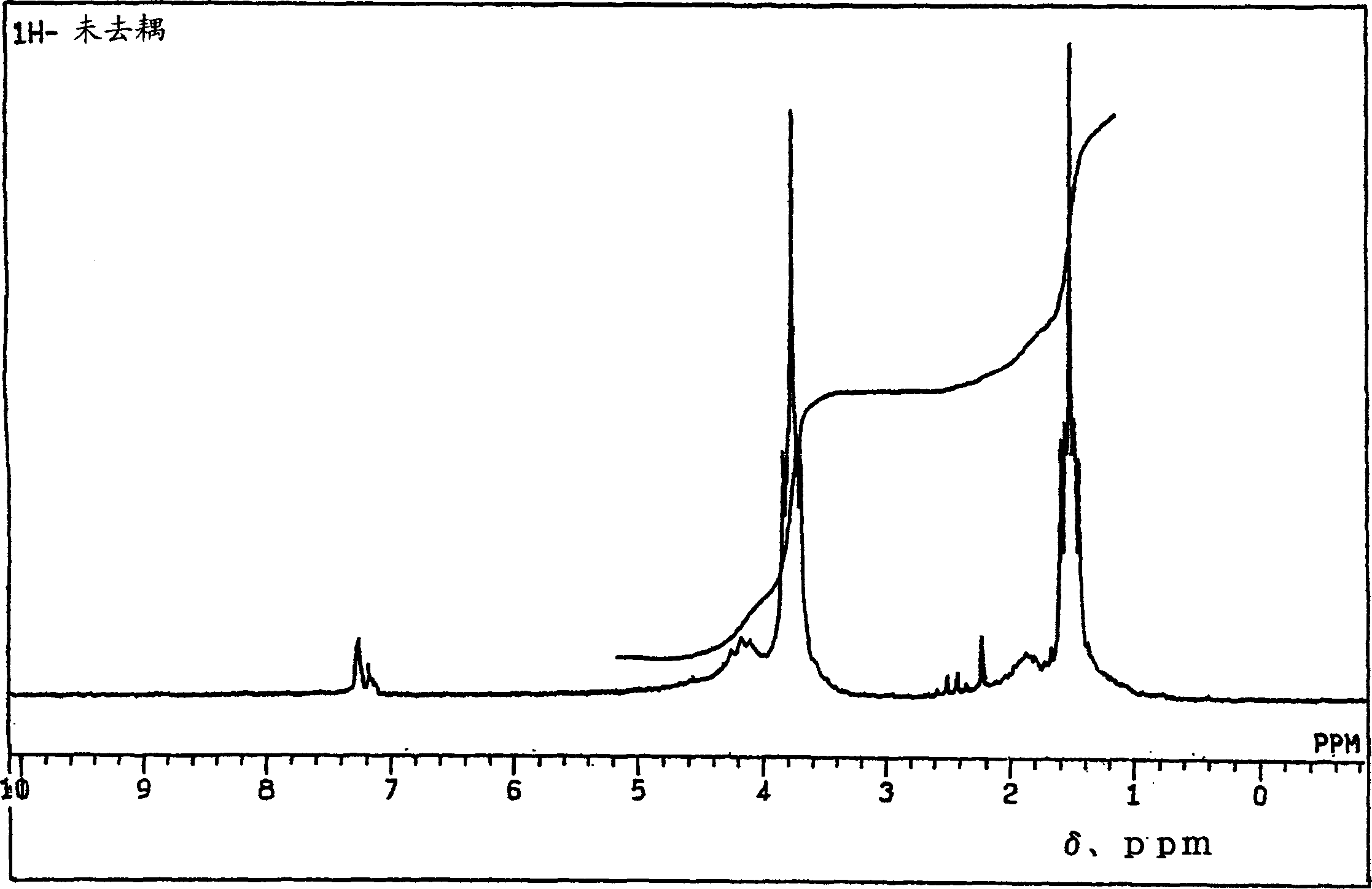

Image

Examples

Embodiment 1

[0050] A glass substrate was immersed in a 1% toluene solution of titanium bis(acetoacetate)diisopropoxide for 1 hour, then baked at 100°C for 30 minutes, and then baked at 300°C for 30 minutes to prepare a hydrophilic substrate. Under nitrogen atmosphere, the complex compound of 10g triethylamine-alane is dissolved in the mixed solvent that 45g toluene and 45g tetrahydrofuran form to make a solution, the solution is coated on the glass substrate with the speed of 1000rpm by spin coating method, immediately apply The coated substrate was prebaked at 110°C to remove the solvent, thereby forming a film composed mainly of triethylamine-alane complex. When the coating film was further heated at 250° C. for 30 minutes and then at 350° C. for 30 minutes in a nitrogen atmosphere to thermally decompose the film, a film having metallic luster was formed on the glass substrate. When the thickness of the film on the substrate was measured with α-step (product of Tenchor Co., Ltd.), the t...

Embodiment 2

[0052] Using the same hydrophilic glass substrate as in Example 1, the oven-dried film was prepared in the same manner as in Example 1, except that 10 g of the ammonia-alane complex was used instead of 10 g of the triethylamine-alane complex. things. When the thickness of the film on the substrate was measured with α-step (product of Tenchor Co., Ltd.), the thickness was 90 nm. In addition, when the conductivity of the film was checked, it was found that the film was conductive, and its surface resistance value was 120 μΩ□.

Embodiment 3

[0054] Using the same hydrophilic glass substrate as in Example 1, a dried film was prepared in the same manner as in Example 1, except that 10 g of triethylamine-alane complex was replaced by 10 g of phenyldimethylamine-alane complex Alane complexes. When the thickness of the film on the substrate was measured with α-step (product of Tenchor Co., Ltd.), the thickness was 85 nm. In addition, when the conductivity of the film was checked, the film was found to be conductive with a surface resistance value of 95 μΩ□.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com