Tunnel effect magneto-resistance device and preparing method

A technology of tunnel effect and magnetoresistance, which is applied in the manufacture/processing of magnetic field controlled resistors and electromagnetic devices, which can solve the problems that the junction resistance cannot return to the initial value, the junction resistance is complex and difficult, etc., and achieve the improvement of magnetic field response characteristics and stability, the preparation method is simple, and the effect of improving the coercive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The present invention must use the following equipment and materials:

[0033] Equipment requirements:

[0034] -Ultrasonic cleaner (the index does not make special requirements);

[0035] -Magnetron sputtering vacuum coating equipment: the ultimate vacuum is 5.0′10-4Pa, the maximum heating temperature of the substrate stage is 1000°C, and the target-base distance is 4.0-4.5cm;

[0036] -Supporting vacuum pump unit for magnetron sputtering vacuum coating equipment:

[0037] The first stage vacuum pump: mechanical pump is adopted, the pumping rate is 8L / s, and the ultimate pressure is 6′10-2Pa;

[0038] The second-stage vacuum pump: molecular pump is adopted, the pumping rate is 600L / s, and the ultimate pressure is 1′10-8Pa;

[0039] -Supporting temperature controller for magnetron sputtering vacuum plating equipment: 818 single-loop process regulator produced by Oulu Company;

[0040] -Ion etching equipment: LKJ-1C-150 ion etching instrument of the 23rd Institute of C...

Embodiment 2

[0063] After completing the preparation steps 1-6 in Example 1, the further preparation steps are as follows:

[0064] 7a. Using the same process as step 1, and using a glass-based mask to prepare a photoresist mask on the surface of the multilayer film;

[0065] 8a. Deposit a layer of Ag on the surface of the multilayer film by using a magnetron sputtering device and in a DC sputtering mode;

[0066] 9a. Immersed in acetone, while removing the photoresist, the noble metal layer above the photoresist is also removed, and the remaining part of the noble metal layer forms a contact electrode;

[0067] 10a. Using indium as solder, solder the conductive leads on the bottom electrode layer and the top electrode layer of the tunnel junction.

Embodiment 3

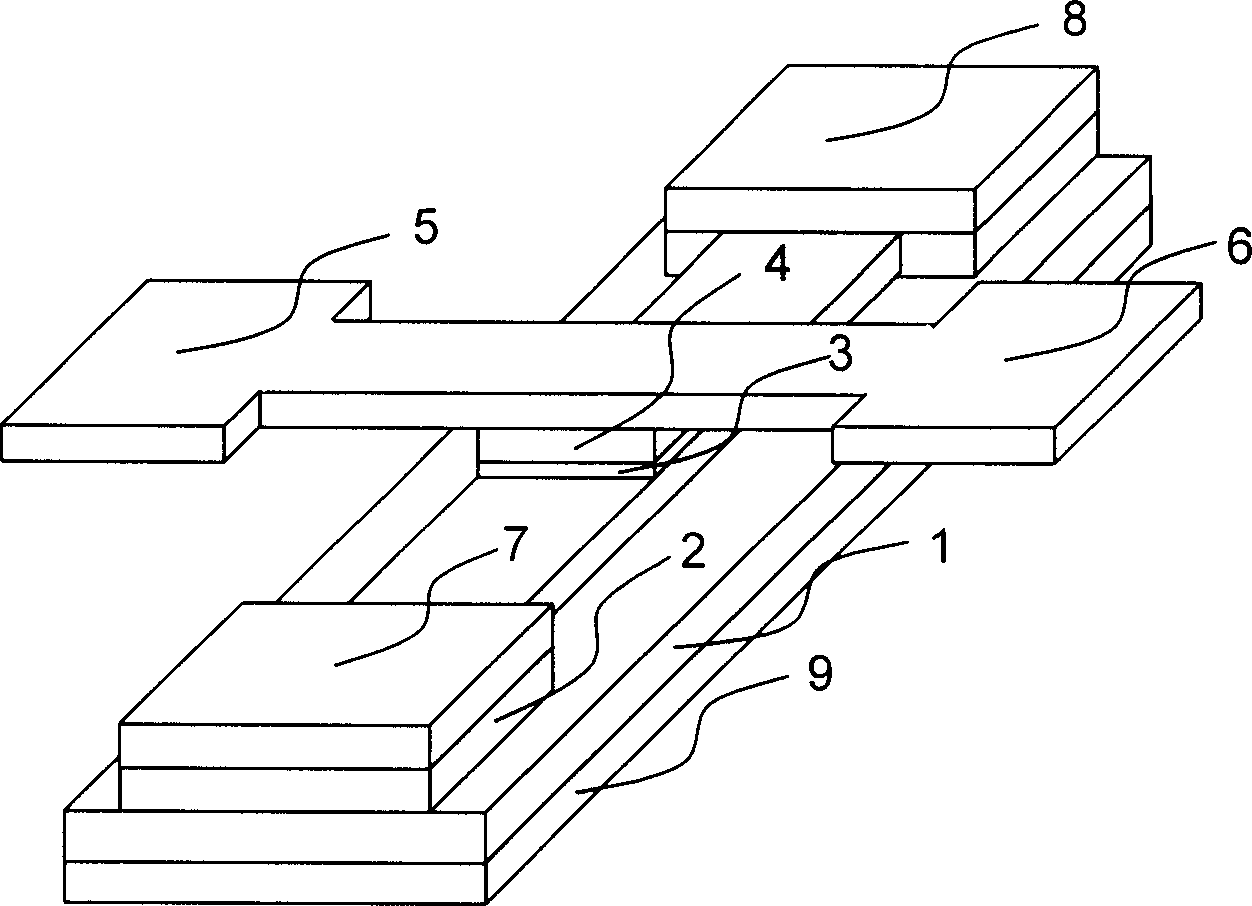

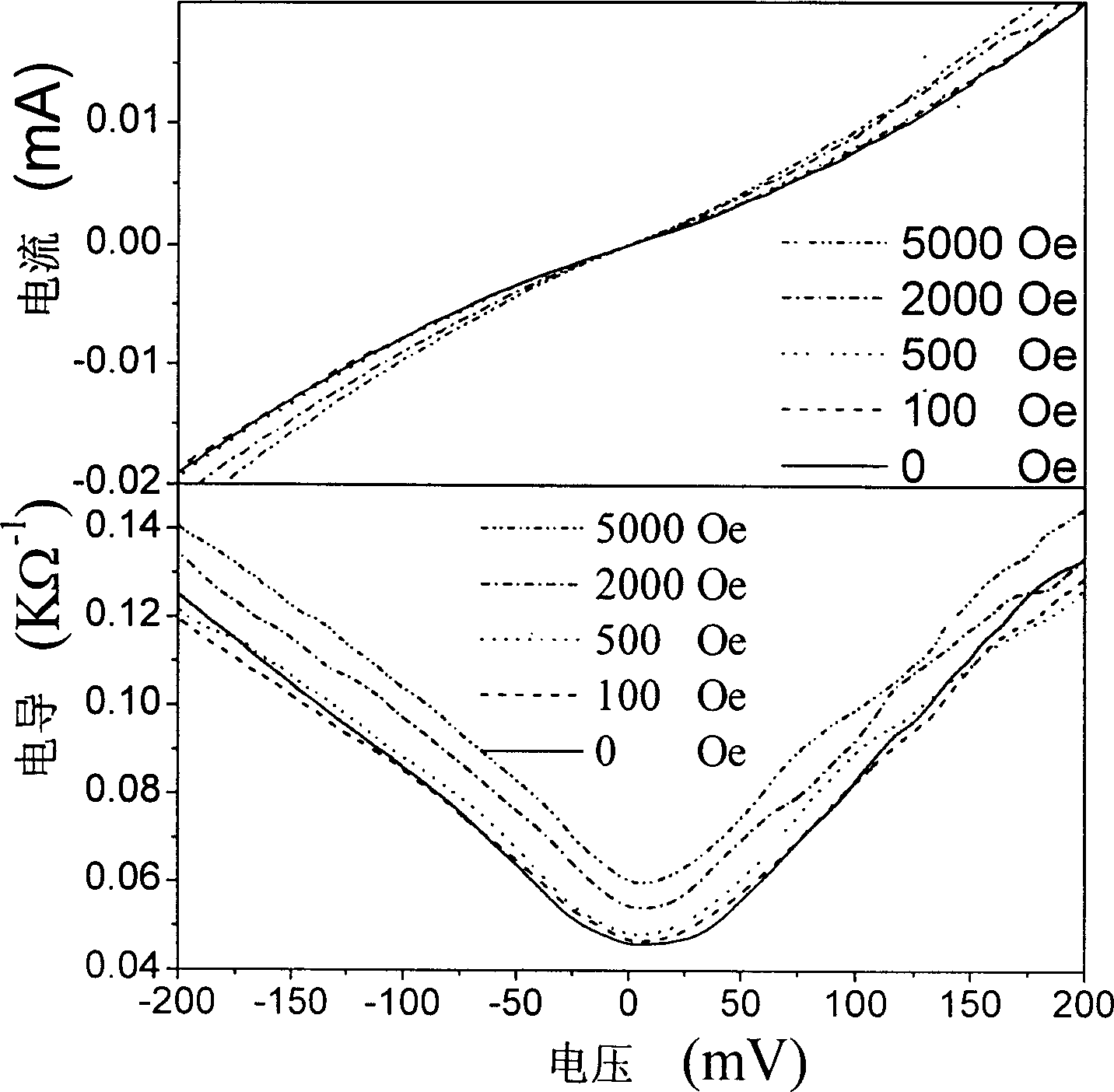

[0069] The tunnel effect magnetoresistance prepared by each step in embodiment 1 or 2 is as follows figure 1 shown. Multilayer films on SrTiO 3 , MgO, Al 2 o 3 or Si wafers as epitaxial growth on the substrate 9, including La with a thickness of 30 or 80nm 0.33 Ca 0.67 MnO 3 Pinning layer 1, La with a thickness of 20 or 100 nm 0.67 Ca 0.33 MnO 3 Bottom electrode layer 2, barrier layer 3 with a thickness of 1 or 8 nm, La with a thickness of 20 or 80 nm 0.67 Ca 0.33 MnO 3 Top electrode layer 4. The barrier layer 3 is located above the bottom electrode layer 2 and below the top electrode layer 4; the antiferromagnetic perovskite manganese oxide compound on the substrate 9 is the pinning layer 1, and the pinning layer 1 is located at the bottom electrode Below layer 2; the bottom electrode layer is strip-shaped, with lead terminals at both ends; above the bottom electrode layer 2 is a square barrier layer 3 and top electrode layer 4, and the top of the top electrode la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com