Preparation of rare earth chloride from long-chain fatty acid extracting transformation and back-extraction process thereof

A long-chain fatty acid, rare earth chloride technology, applied in the direction of improving process efficiency, can solve problems such as difficult degradation, pollute the environment, and process discontinuity, and achieve the effects of less consumption of chemical reagents, reduced environmental pollution, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

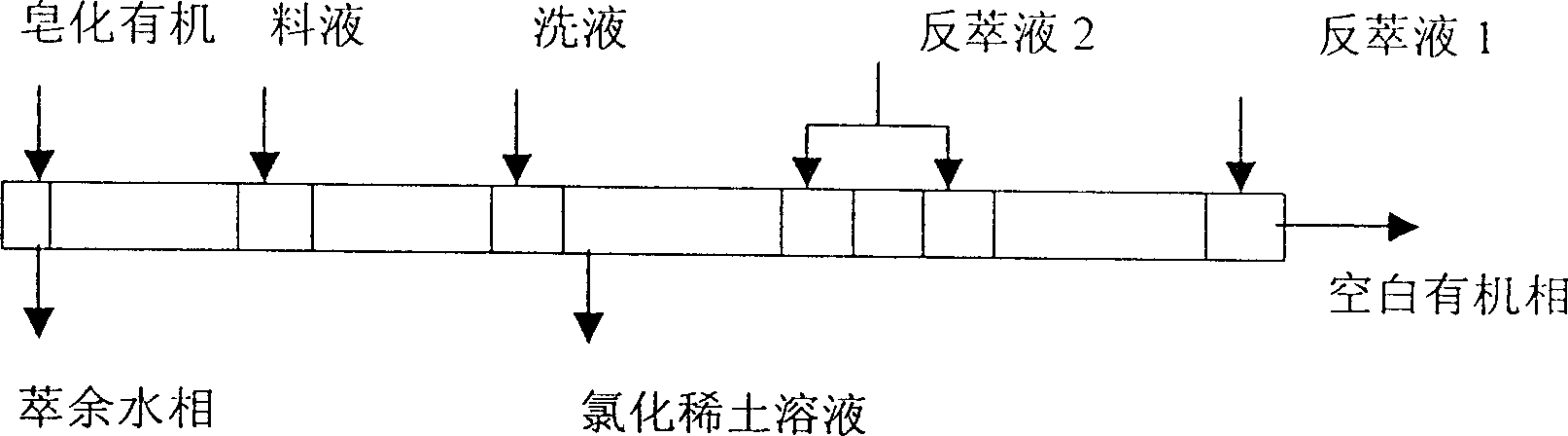

Embodiment 1

[0012] Example 1: A rare earth enterprise in Baotou concentrated sulfuric acid high-temperature roasting water immersion solution, rare earth sulfate solution after removing impurities by magnesium oxide, that is, the feed liquid used for carbon precipitation in the original process, rare earth concentration 38g / l, acidity PH4, organic phase composition It is fatty acid 1.0M-isooctanol 15% V / V-sulfonated kerosene, concentrated ammonia water saponification, saponification degree is 0.4M, 3-stage extraction, 2-stage washing, 5-stage stripping, organic phase: feed liquid: washing liquid: Stripping liquid 1: the flow ratio of stripping liquid 2 is 3: 1: 0.5: 0.18: 0.06, the rare earth chloride solution concentration that obtains is 205g / l, and acidity is PH1, and sulfate radical content is less than 0.02%, and rare earth yield is greater than 99%.

Embodiment 2

[0013] Example 2: A rare earth enterprise in Baotou concentrated sulfuric acid high-temperature roasting water immersion solution, rare earth sulfate solution after removing impurities by magnesium oxide, that is, the feed liquid used in the original process for P204 extraction transformation, rare earth concentration 36g / l, acidity PH2, other conditions Same as Example 1, the concentration of the obtained rare earth chloride solution is 203g / l, the acidity is PH1, the sulfate content is less than 0.02%, and the rare earth yield is greater than 99%.

Embodiment 3

[0014] Embodiment 3: The feed liquid is the same as in Example 1, the organic phase is composed of fatty acid 0.85M-isooctanol 15% V / V-sulfonated kerosene, saponified with concentrated ammonia water, and the degree of saponification is 0.4M. 3-stage extraction, 2-stage washing, 5-stage back-extraction, the flow ratio of organic phase: feed liquid: washing liquid: stripping liquid 1: stripping liquid 2 is 4: 1: 1: 0.18: 0.04, and the obtained rare earth chloride The solution concentration is 184g / l, the acidity is PH2, the sulfate radical content is less than 0.02%, and the rare earth yield is greater than 99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| saponification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com