Method for mfg. organic electroluminescent display panel covered with protective film

A manufacturing method and technology of protective film, applied in the direction of electroluminescence light source, electric light source, light source, etc., can solve the problems of long sealing process time, increase the cost of raw materials, shorten the life of accessories, etc., to overcome manufacturing difficulties, improve production efficiency, The effect of simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

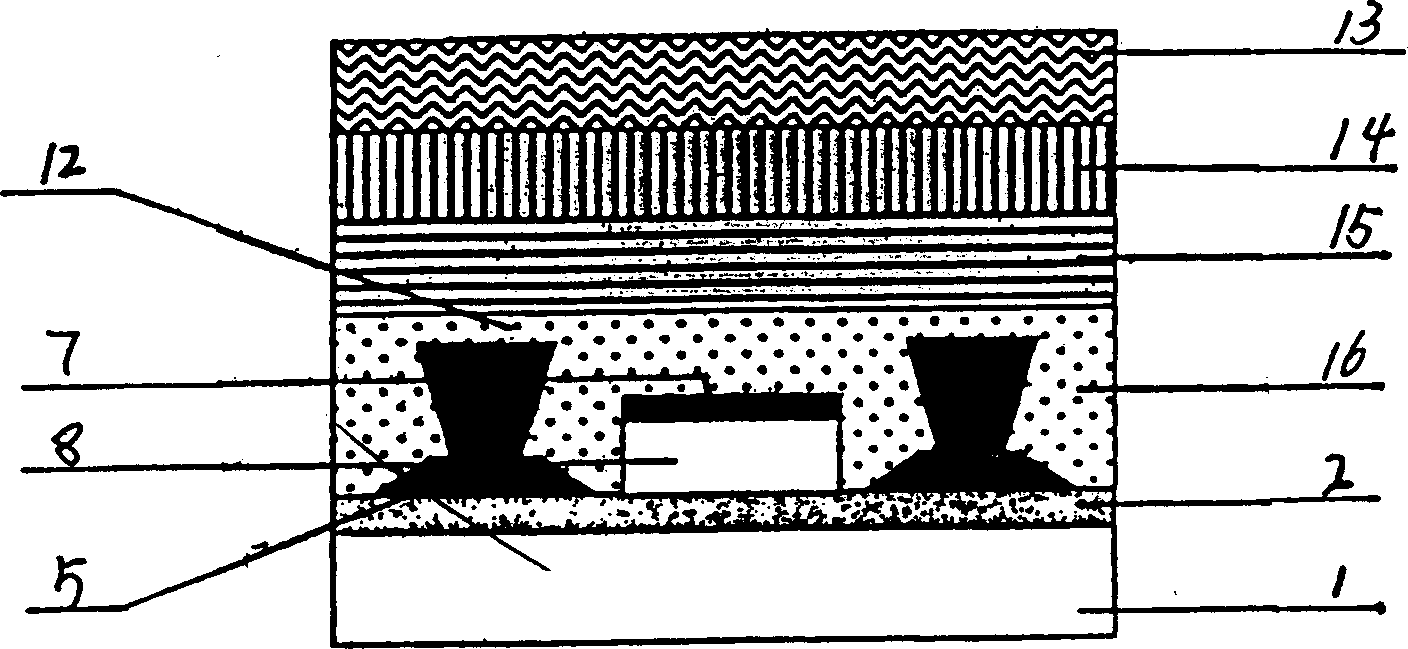

[0024] Such as Figure 4 Shown, the manufacturing process of parylene dimethyl (Parylene) film: heating dimer (Dimer) parylene dimethyl (Di-para-xylylene) to 150 degrees Celsius under the pressure of 1.0 torr , decomposed into monomer (Monomer) polyparaxylylene dimethyl Paraxylylene, and then sprayed into the reaction chamber (Chamber) at a pressure of 0.5 Torr not higher than 680 degrees Celsius, and at a pressure of 0.1 Torr at 25 degrees Celsius The formation of polymer (Polymer) poly-p-phenylene dimethyl Poly (para-xylylene), that is, the formation of a film.

Embodiment 2

[0026] Such as Figure 5 As shown, the silicone resin refers to a polymer (Polymer) containing an organic group connected by a Si-O-Si combination of silicon and oxygen. Therefore, it has both organic and inorganic properties. That is, analyzing the molecular structure of silicone resin, due to the combination of Si-O-Si, it has inorganic properties such as heat resistance, chemical stability, wear resistance, and high gloss; at the same time, because of the organic properties of its side chains, it has Excellent reactivity, solubility, productivity, etc. According to the different forms of silicone resin, it is divided into oil (oil), rubber (Rubber), resin (resin) and other types. The higher the degree of cross-linking of silicon (Silicon Resin), the lower the activity and stretchability of the molecule, and the higher the hardness. The product with extremely high cross-linking density is silicone resin (Silicone Resin).

Embodiment 3

[0028] Such as Figure 6 As shown, the chemical basic unit of epoxy resin must contain epoxy (Epoxy) structure, which is usually produced by neutralizing epichlorohydrin and bisphenol A. Epoxy resins are difficult to use alone and require the addition of a hardener. Therefore, epoxy resins in the strict sense are intermediate products. Because bisphenol A epoxide is produced by the reaction of 2,2-bis-p-hydroxyphenylpropane BPA (Bisphenol A) and chloromethoxycyclopropane ECH (ie Epichlorohybrine), it belongs to the benzene ring nucleus (Bisphenol A), so it is difficult to rotate freely . Therefore, its chemical resistance, adhesive force, toughness, high temperature resistance and other properties are outstanding. Moreover, the ether (Ether) group inside its molecule can improve drug resistance and plasticity. Hydrophilic hydroxyl groups and hydrophobic hydrocarbon groups are regularly arranged, so its adhesive force is excellent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com