Mfg. appts. of electronic device, mfg. method of electronic device and mfg. program of electronic device

A technology for electronic devices and manufacturing devices, which is applied to the assembly of printed circuits with electrical components, semiconductor/solid-state device manufacturing, and electrical solid-state devices. Changes, shortening of production cycle time, and the effect of preventing quality deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0132] Hereinafter, an electronic device manufacturing apparatus and a manufacturing method thereof according to an embodiment of the present invention will be described with reference to the drawings.

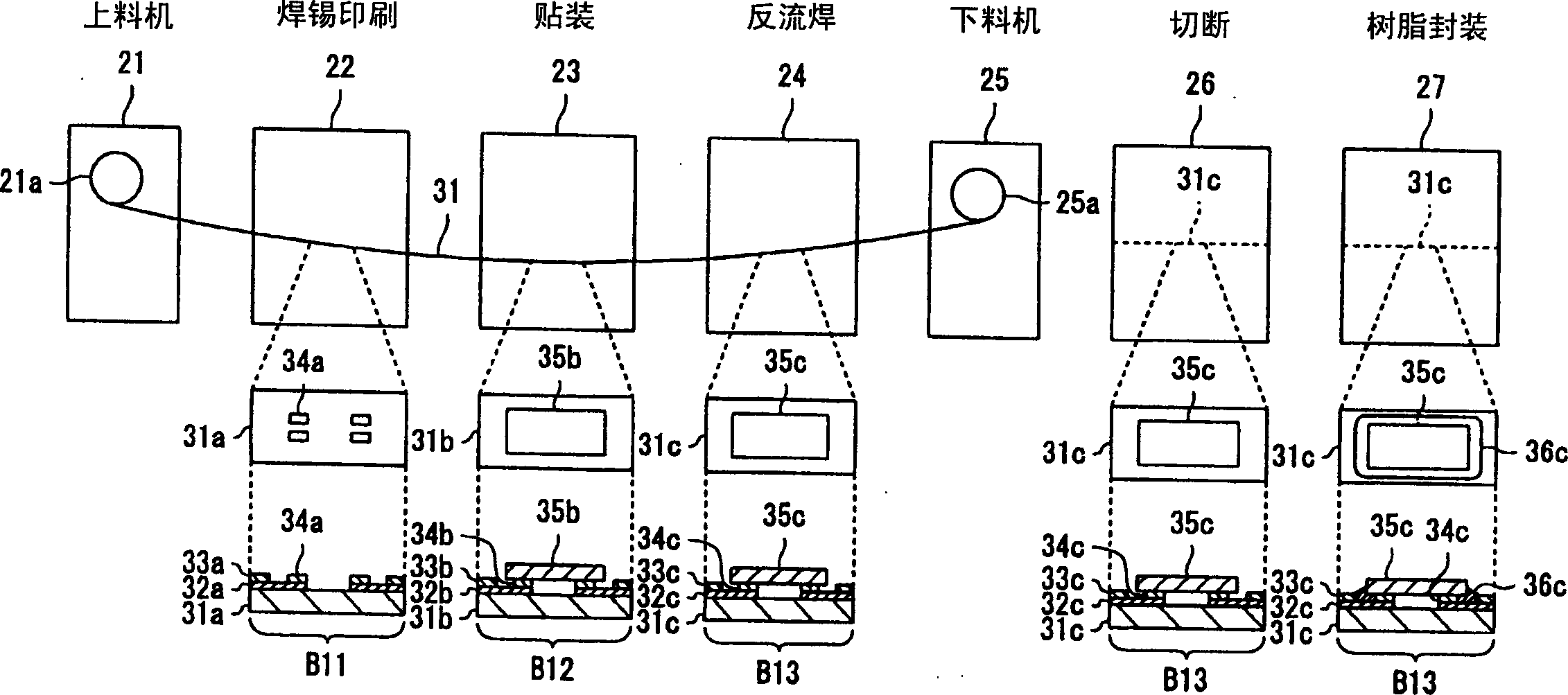

[0133] figure 1 A method of manufacturing an electronic device according to a first embodiment of the present invention is shown.

[0134] exist figure 1 Among them, a solder coating section 22 , a mounting section 23 and a reflow soldering section 24 are arranged side by side between the loader 21 and the unloader 25 along the transport direction of the tape carrier substrate 31 .

[0135] On the other hand, on the tape carrier board 31 , electronic component mounting regions are provided on the respective circuit blocks B11 to B13 , and circuit boards 31 a to 31 c are provided on the respective circuit blocks B11 to B13 . Then, wirings 32a to 32c are formed on the respective circuit boards 31a to 31c, and insulating films 33a to 33c are formed on the respective wirings 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com