Processing method for small motor commutator assembly and small motor and equipment mounted with said commutator assembly

A processing method and technology for commutators, which are applied in electrical components, electromechanical devices, DC commutators, etc., can solve the problems of out-of-round commutator components, shortened motor life, difficulties, etc., to achieve high social and economic value, reduce Processing cost, strong vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

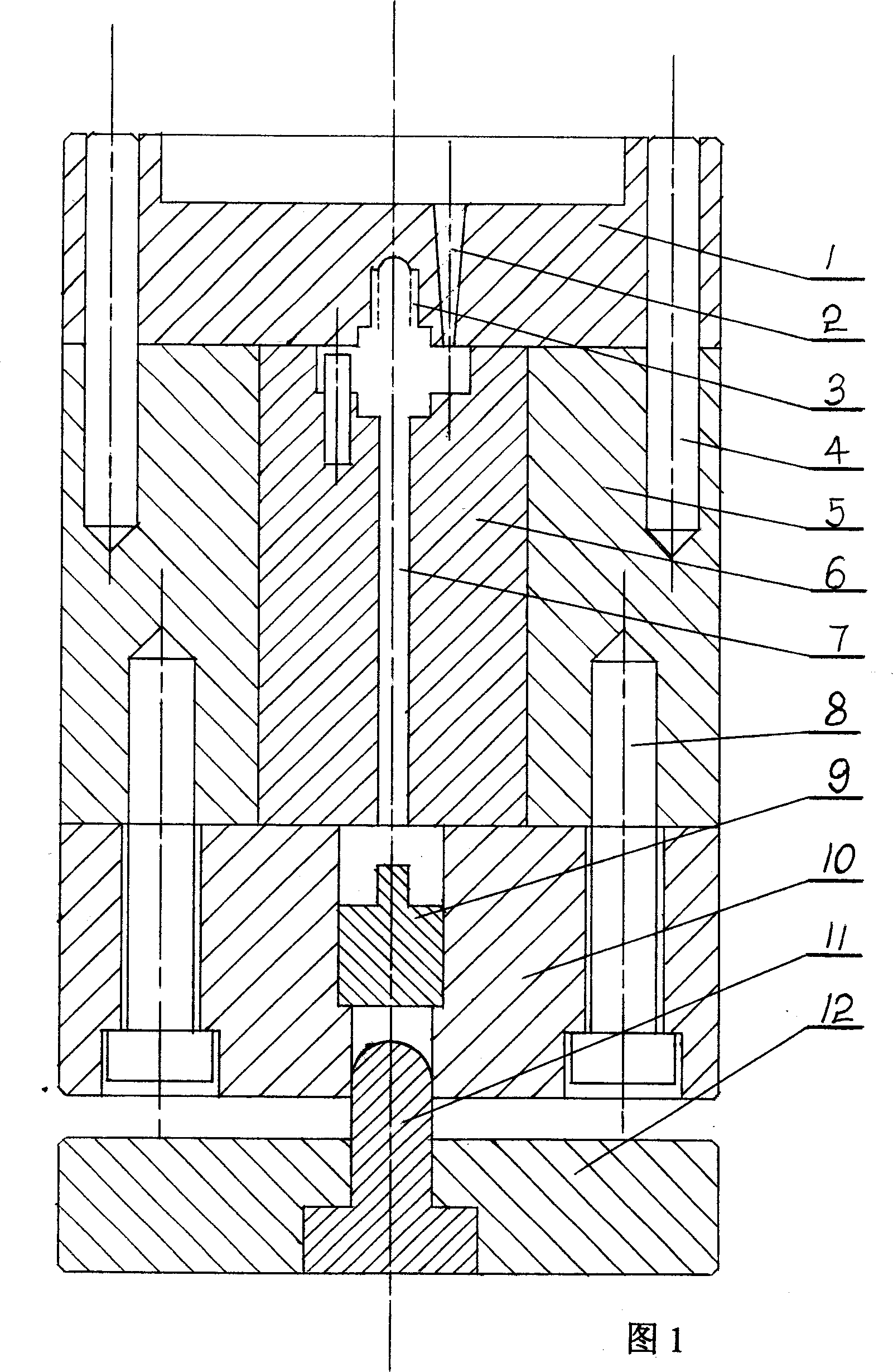

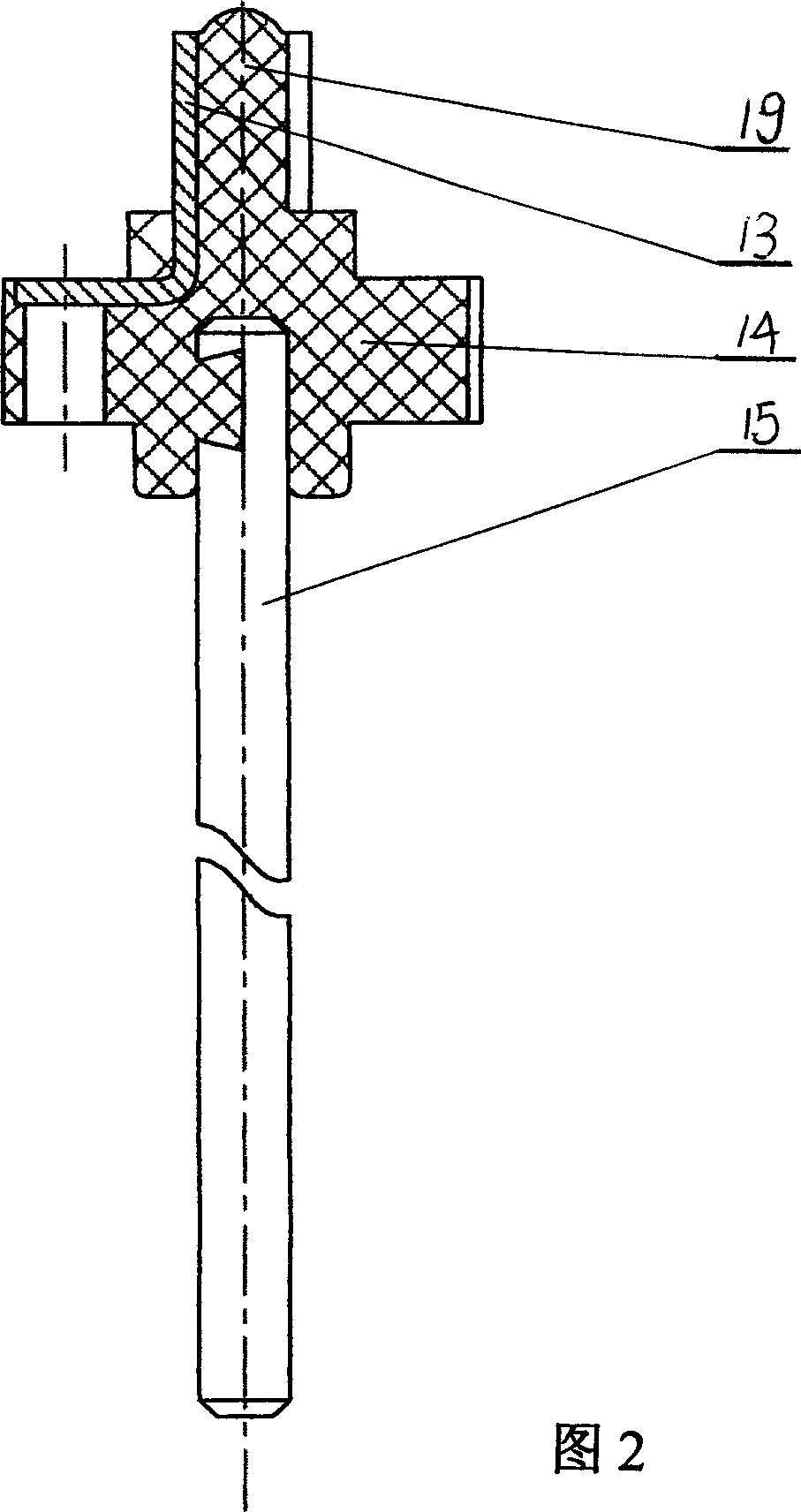

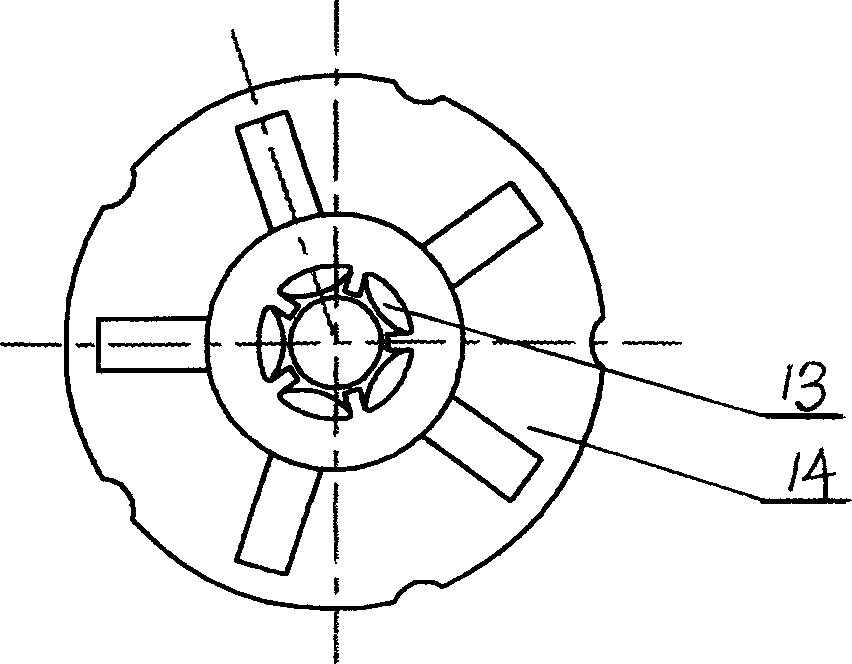

[0012] Fig. 1 is an overall cross-sectional view of the injection mold of the rectifier subassembly of the present invention, including an upper template (1), an injection port (2), and the upper template (1) is connected to the lower template (5) through a positioning pin (4). Wherein in lower formwork A (5) mold core (6) is installed, central axis (13) positioning hole (7) is arranged on the mold core (6). The lower formwork A (5) is connected with the lower formwork B (10) through the positioning screw (8), and the thimble (9) is installed in the middle of the lower formwork B (10), and the ejector block (11) and the thimble are arranged on the thimble plate (12). (9) Tangent. The specific method is to allow the worker to insert the commutator (14) into the positioning groove (3), and then insert the central axis (15) into the positioning hole (7) of the central axis (15) of the mold core B (5). Then let the upper template (1) and the lower template A (5) overlap through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com