Liquid composition for removing residue of photo-corrosion-inhibitor

A technology for photoresist and residue removal liquid, applied in the field of photoresist residue removal liquid composition), can solve the problems of unpreferable environment, unsatisfactory corrosion inhibitor and the like, and achieve excellent removability, prevent The effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Examples of the aliphatic polyhydric carboxylic acid and its salt used in the photoresist residue removing liquid composition of the present invention include dibasic carboxylic acids such as oxalic acid, malonic acid, tartaric acid, and succinic acid, and hydroxy dicarboxylic acids such as malic acid. Hydroxytricarboxylic acids such as polycarboxylic acids and citric acid, salts thereof, and the like.

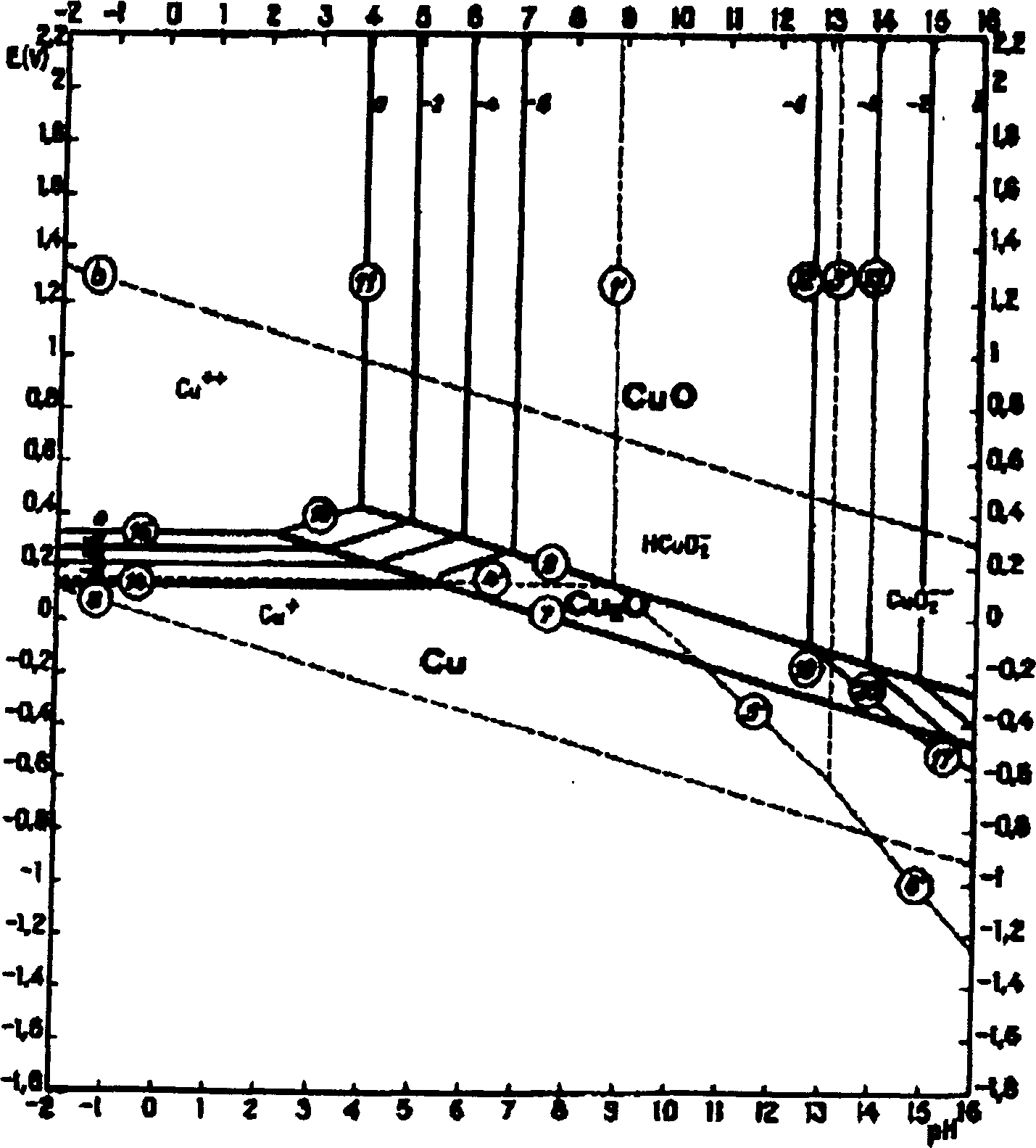

[0042] The composition of the photoresist residue remaining after grinding and polishing differs depending on the material to which dry etching is performed. When dry etching is performed on the interlayer insulating film on the copper wiring, the photoresist residue present on the bottom surface and sidewall of the via hole after grinding and polishing contains copper oxide. Therefore, aliphatic polyhydric carboxylic acid is mentioned as a component which removes a photoresist residue, and can be dissolved and removed by suitably selecting a case. In addition, in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com