Gear and its production method

A processing method and gear technology, applied to components with teeth, belts/chains/gears, portable lifting devices, etc., can solve the problems of high cost per piece of gears and expensive equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

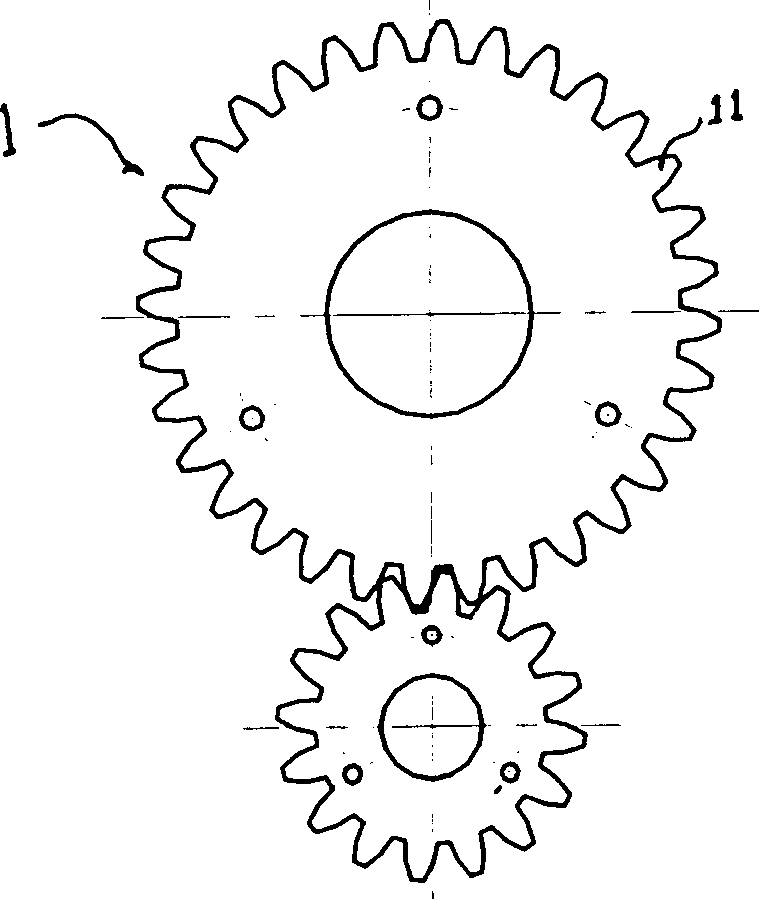

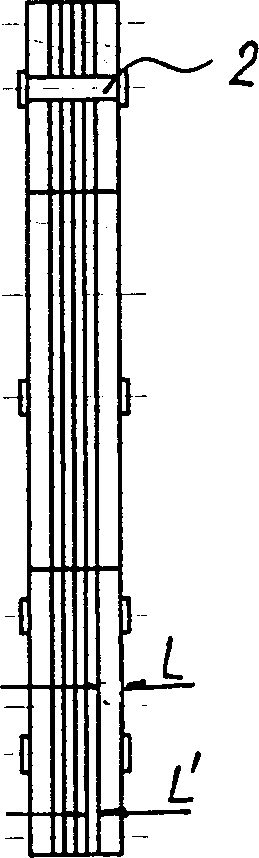

[0024] The laminated gear of the present invention can form various transmission modes according to transmission requirements. Such as Figure 1~2 The first type of spur gear shown is formed by superimposing several identical gear pieces 1 with tooth profiles 11 aligned, and the pieces are fixedly connected by rivets 2 . The thickness L of the tooth pieces on the left and right sides of the gear is greater than the thickness L' of the middle tooth piece.

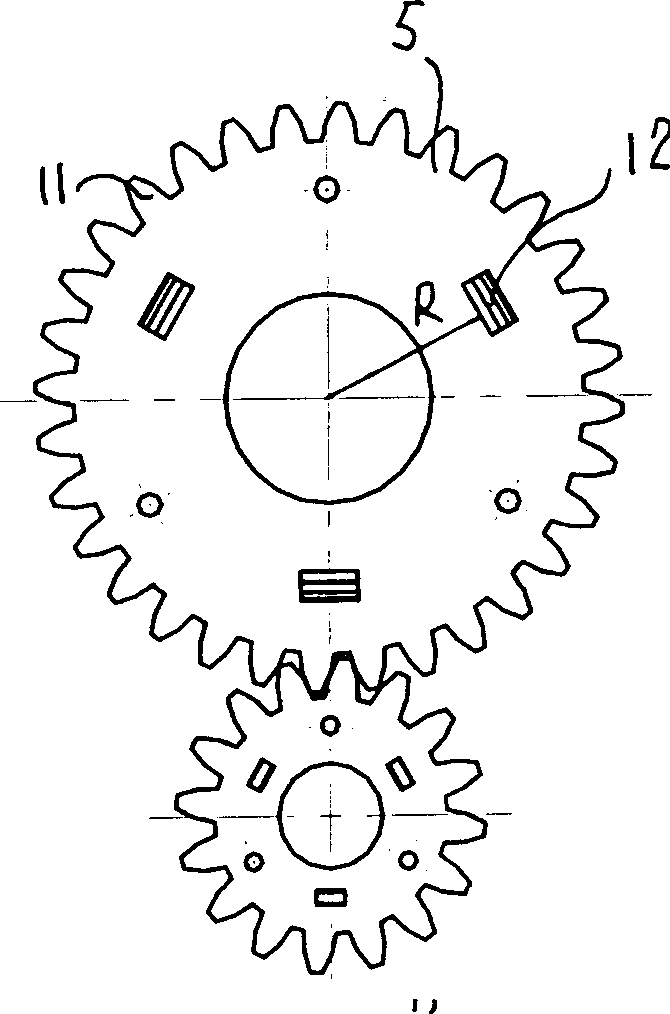

[0025] Such as Figure 3-5 The second type of spur gear shown is composed of a number of identical gears 5 stacked in alignment with each tooth profile 11. Except for the outer gear 5', the rest of the gears are at a distance of radius R from the center of the circle. There are evenly distributed concave-convex points 12 punched on the circumference, and the convex part of the concave-convex point 12 of the previous tooth piece is embedded in the concave part formed by the concave-convex point of the next tooth piece; Con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com