Carbon atom wire and process for preparing carbon nanotube and carbon atom wire by pyrolyzing solid-state carbon source

A technology of carbon nanotubes and solid carbon source, which is applied in the field of preparing carbon nanotubes and carbon atomic wires, can solve the problems of low yield of carbon nanotubes and the like, and achieve the effects of low price, low cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

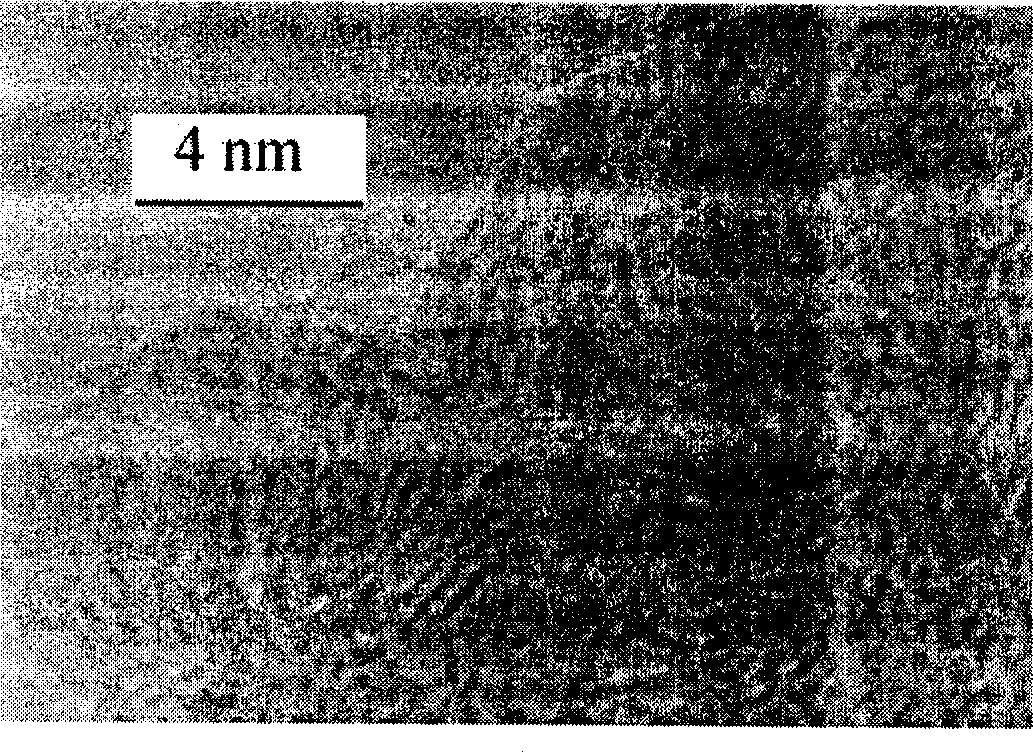

[0021] Embodiment 1, with 2g 0.2mol / L Fe (NO 3) 3 The solution was mixed with 3.5g of potato starch evenly, then added into a ceramic burning boat, vacuum dehydrated at room temperature for 1 hour, put into a tube furnace whose reaction tube could be isolated from the outside air, vacuumed, filled with Ar gas, and repeated three times to remove the original substance in the furnace tube. Some air, 30mL / min of Ar and 30mL / min of H under the pressure of 0.2Mpa 2 steady airflow. Raise the temperature to 500°C at a rate of 15°C / min, keep the temperature for 5 hours, then raise the temperature to 700°C at a rate of 15°C / min, cool down to room temperature naturally after 15 hours at a constant temperature, and stop the gas. Discharge, obtain product 1.0g. The obtained product without any purification is observed under the transmission electron microscope (TEM) in the morphology shown in Figure 10 . From the TEM image, it can be seen that impurities such as amorphous carbon are...

Embodiment 2

[0022] Embodiment 2: substantially the same as embodiment 1, but the reactant is cotton cellulose. Figure 11 It is the morphology of the product obtained in this example without any purification treatment under a transmission electron microscope. It can be seen from the TEM image that the product obtained is also of high purity, and the diameter of the obtained carbon nanotubes is also very uniform, about 20 nm.

Embodiment 3

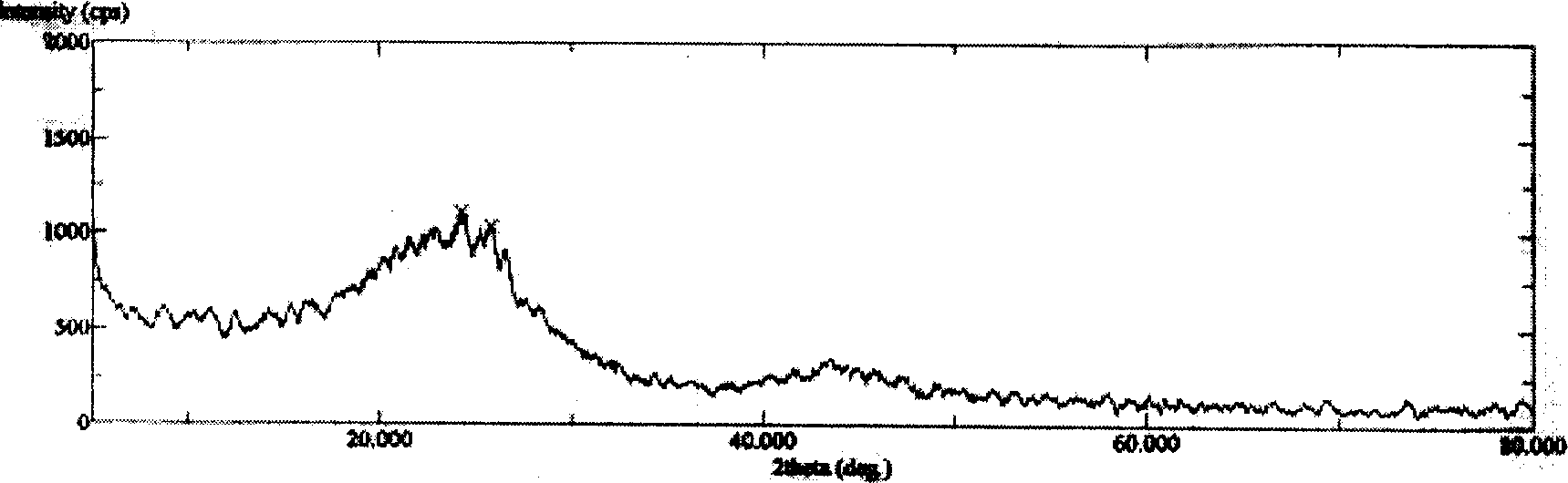

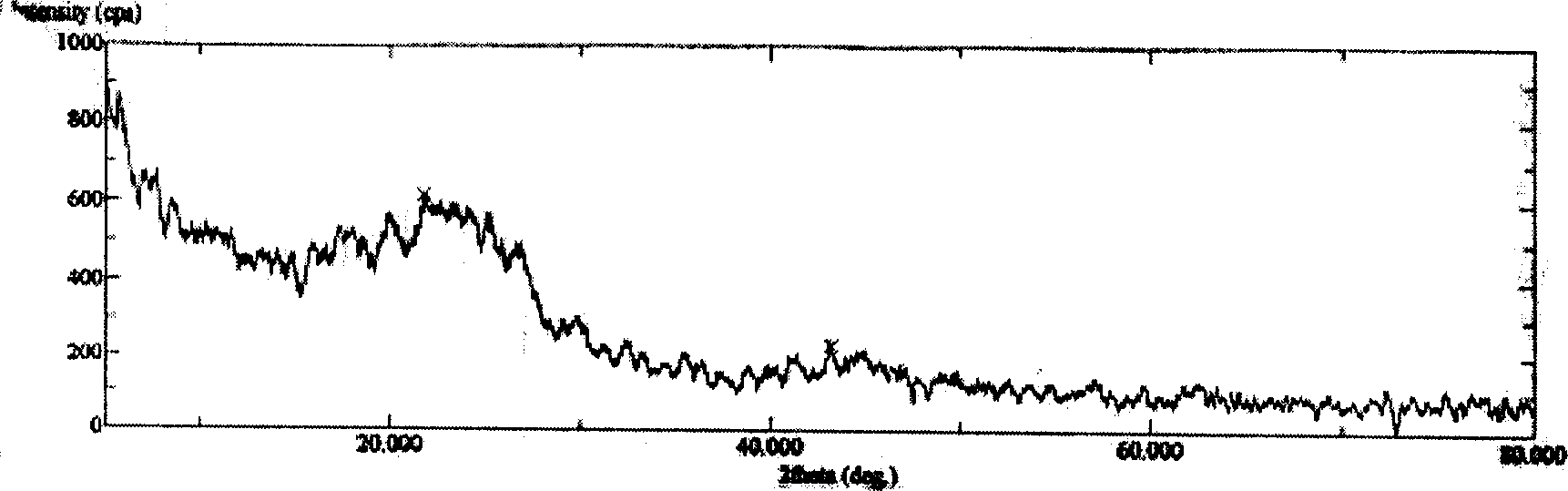

[0023] Embodiment 3: reactant is 2.3g potato starch, the aqueous solution of 0.23g polyacrylic acid iron resin (wherein containing polyacrylic acid resin 76%, Fe0.034%, all the other are water) and 1.0g 2.0%Fe (NO 3 ) 3 , the post-treatment temperature is 800°C. Polyacrylic resin is polymerized by acrylic acid and styrene at a mass ratio of 4:1. This embodiment obtains product 0.63g. The morphology of the purified carbon atomic wires observed under the high-resolution transmission electron microscope (HRTEM) is shown in Fig. figure 1 . The X-ray diffraction (XRD) figure of the obtained carbon atom line after purification is shown in figure 2 . The photoelectron spectroscopy (XPS) figure of the obtained carbon atomic line after purification is shown in Figure 4 and Figure 6 . The Auger Electron Spectrum (AES) diagram of the obtained carbon atomic line after purification is shown in Figure 8 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com