Zinc electrode material for secondary battery using Zn as negative electrode and its preparing process

A secondary battery, zinc electrode technology, applied in battery electrodes, electrode manufacturing, circuits, etc., can solve the problems of inability to comprehensively improve the performance of zinc electrodes, limit the practical application of secondary batteries, expensive zinc electrode costs, etc., to improve zinc deposition. performance, reducing corrosion current density, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Preparation of Zn by solid phase diffusion method 100-x La x alloy. Mix the Zn and La metal powders over 300 mesh evenly according to the stoichiometric ratio (where x=0.1, 1), grind for 4 hours, put them into a special mold, and press them into an ingot under a pressure of 30 MPa. Then put the metal ingot into a stainless steel reactor, fill it with 5MPa high-purity Ar gas, seal the reactor, put it into a tube furnace, heat it to 370°C, diffuse it for 8 hours to form an alloy, and then cool it naturally After reaching room temperature, the obtained product was mechanically pulverized and set aside.

Embodiment 2

[0018] Preparation of Zn by solid phase diffusion method 100-x Mmm x Alloy (Mm is lanthanum-rich mixed rare earth, the percentages of main elements are: La: 51.38%; Ce: 28.32%; Pr: 3.92%; Nd: 16.38%). Weigh 300-mesh Zn and Mm metal powders (where x=0.1, 1) according to the formulated alloy composition, mix them evenly, grind them with an agate mortar for 5 hours, and press the ground powders into circular pieces under a pressure of 25 MPa , and then sealed in a stainless steel container, after vacuuming and gas washing, filled with 7.5MPa high-purity Ar gas, put the stainless steel container into a tubular resistance furnace, heated to 420 ° C, and diffused at a constant temperature for 10 hours to make it in solid state Diffusion in the phase to form an alloy, naturally cooled to room temperature, mechanically crushing the obtained alloy, and set aside.

Embodiment 3

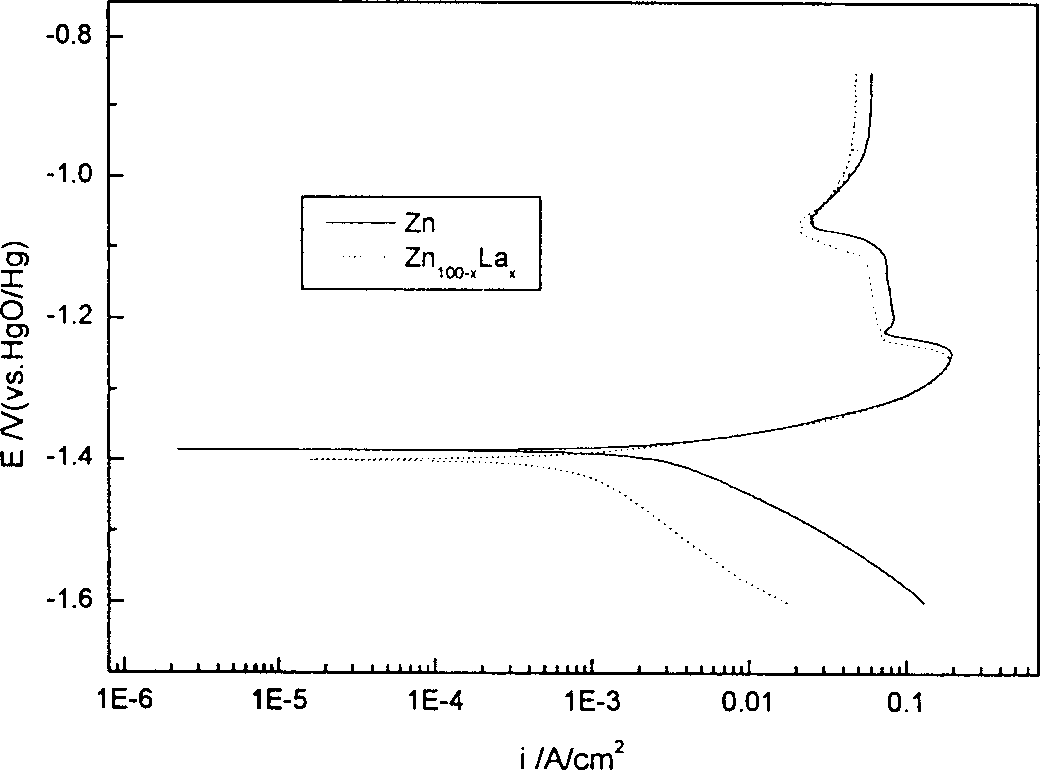

[0020] The alloy prepared in Example 1 was prepared into an as-cast electrode, and the electrochemical performance test was carried out in a 5M KOH solution, and compared with a pure Zn electrode, the obtained corrosion curve is shown in Figure 1, and the data are shown in Table 1:

[0021] Table 1 Zn 100-x La x Potentiostatic Polarization Curve Parameters of Alloy Electrode and Pure Zn Electrode

[0022] Alloy

i corr / mA / cm 2

b a / mV

b c / mV

η / V(0.02A / cm 2 )

p / V

Zn

3.89

45

128

0.088

-1.256

Zn 100-x La x

0.81

36

162

0.214

-1.253

[0023] Note: i corr is the corrosion current density; b a is the anode Tafel slope; b c is the cathode Tafel slope; η is the hydrogen evolution overpotential;

[0024] p passivating potential

[0025] From Figure 1 and Table 1, it can be seen that compared with pure Zn electrodes, Zn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com