Production process of quarternary carbonate powder

A manufacturing process, carbonate powder technology, applied in the preparation of carbonate/acid carbonate, calcium carbonate/strontium/barium, rare earth metal compounds, etc., can solve the problem of uneven dispersion of scandium oxide and cathode emission current Density Inconsistencies, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

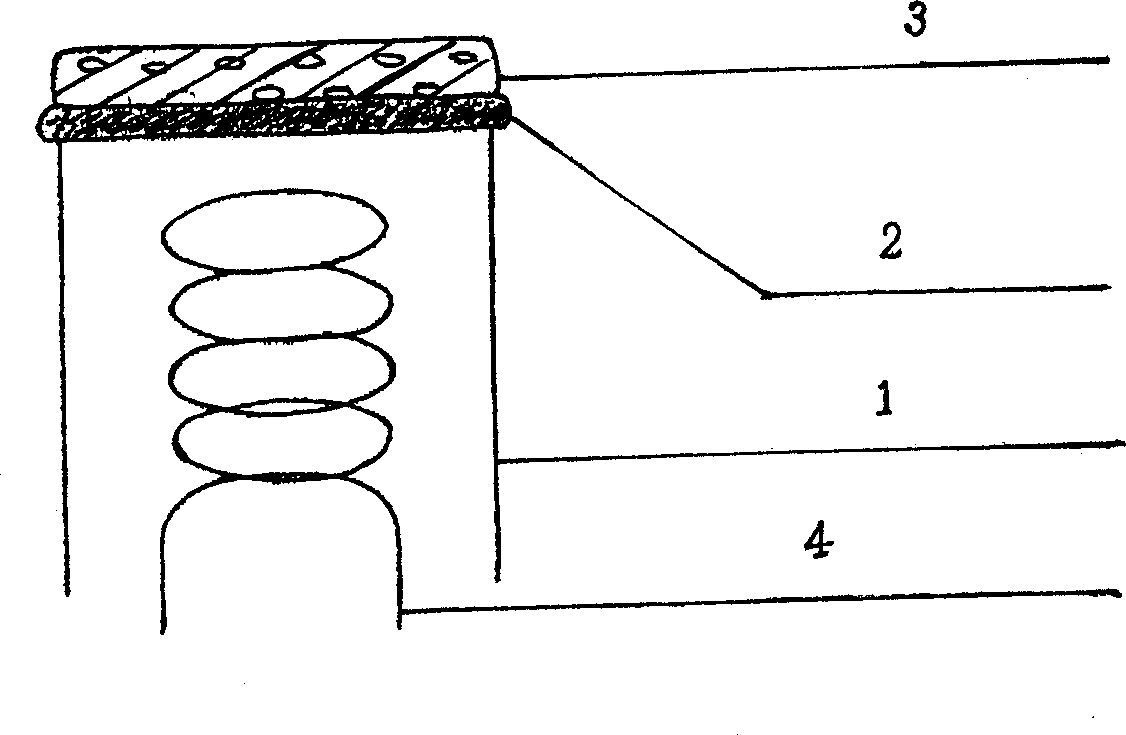

Image

Examples

Embodiment Construction

[0043] Raw material proportioning of the present invention is as follows:

[0044] Barium nitrate 30g

[0045] Strontium nitrate 23 grams

[0046] Calcium nitrate 4 g

[0047] scandium oxide 1 g

[0048] Hydrochloric acid (concentration 20%) 6 grams

[0049] Sodium carbonate 30g

[0050] 0.7 liters of water

[0051] Manufacturing process of the present invention is as follows:

[0052] 1. Preparation of scandium chloride solution: add scandium oxide into hydrochloric acid with a concentration of 20% to react to form a scandium chloride solution.

[0053] 2. Preparation of nitrate solution: weigh barium nitrate, strontium nitrate, calcium nitrate and scandium chloride solution according to the above formula and add them into 80°C hot industrial pure water and stir to dissolve.

[0054] 3. Preparation of sodium carbonate solution: Dissolve sodium carbonate in 80°C hot industrial pure water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com