Process for preparing nylon 6/montmorillonite composite

A technology of montmorillonite and composites, applied in the field of polymer nanocomposite materials, can solve the problems of insufficient economical environmental pollution, long reaction time, etc., and achieve the effects of reducing environmental pollution, shortening reaction time, and uniform performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

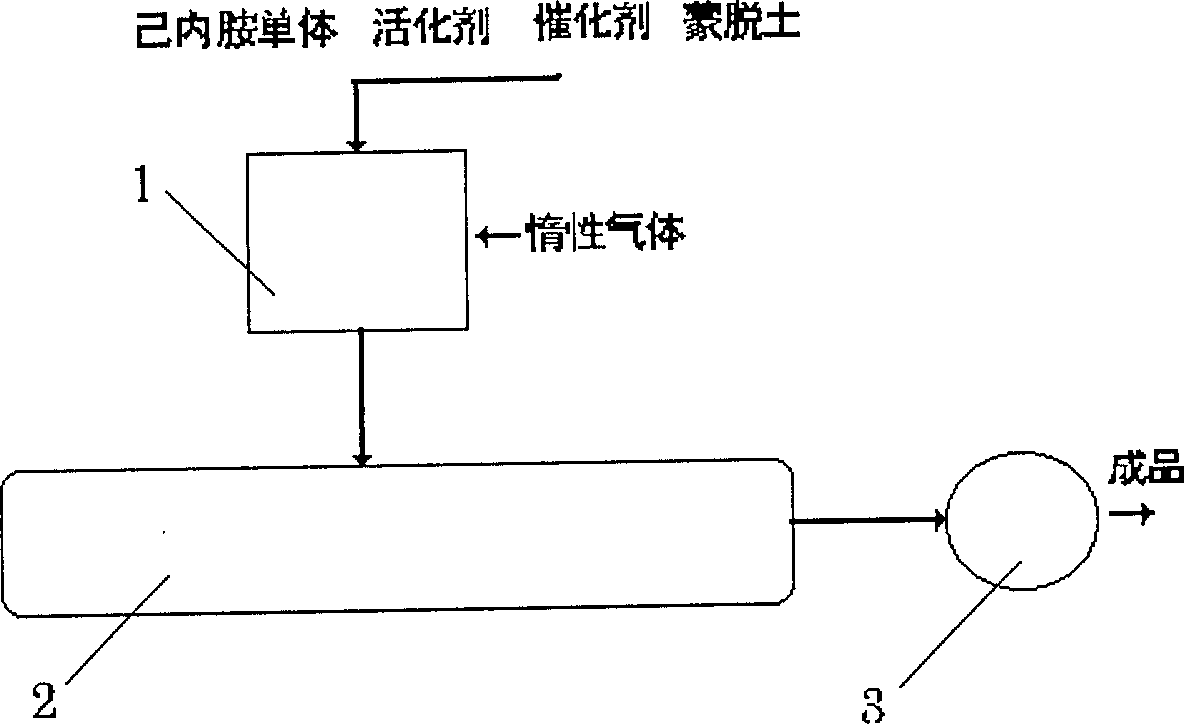

Image

Examples

Embodiment 1

[0033] Feed caprolactam monomer, catalyst sodium caprolactam, and activator 2-4 xylene diisocyanate in proportions of 98%, 1% and 1% by mass, add to the pretreatment tank, start vacuuming and stir.

[0034] Then the temperature of the pretreatment tank was raised to 100°C to melt the monomer. After the temperature rises to 100°C, vacuum is maintained for about 2 hours to remove water in the system as much as possible.

[0035] After dehydration is completed, fill with nitrogen (pressure is 0.1kg / cm 2 ) to protect the material in the kettle, then add 3% montmorillonite by mass percentage, continue to vacuumize for 30 minutes, and fill with nitrogen for protection. Then let the mixed melt continue to stir in the pretreatment tank for 15 minutes to complete the preparation of the polymerization active material.

[0036]After the preparation of the polymer active body is completed, open the ball valve at the lower part of the pretreatment tank, let the active body be injected in...

Embodiment 2

[0040] Same as Example 1, only the amount of montmorillonite accounted for 5% of the total weight, to prepare nylon / montmorillonite composite.

Embodiment 3

[0042] Same as Example 1, only the amount of montmorillonite accounted for 7% of the total weight, to prepare nylon / montmorillonite composite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com